Charging optimization method of lithium ion battery

A technology of lithium ion battery and optimization method, applied in the field of lithium ion battery, can solve problems such as capacity loss, and achieve the effect of reducing charging time, easy to implement, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

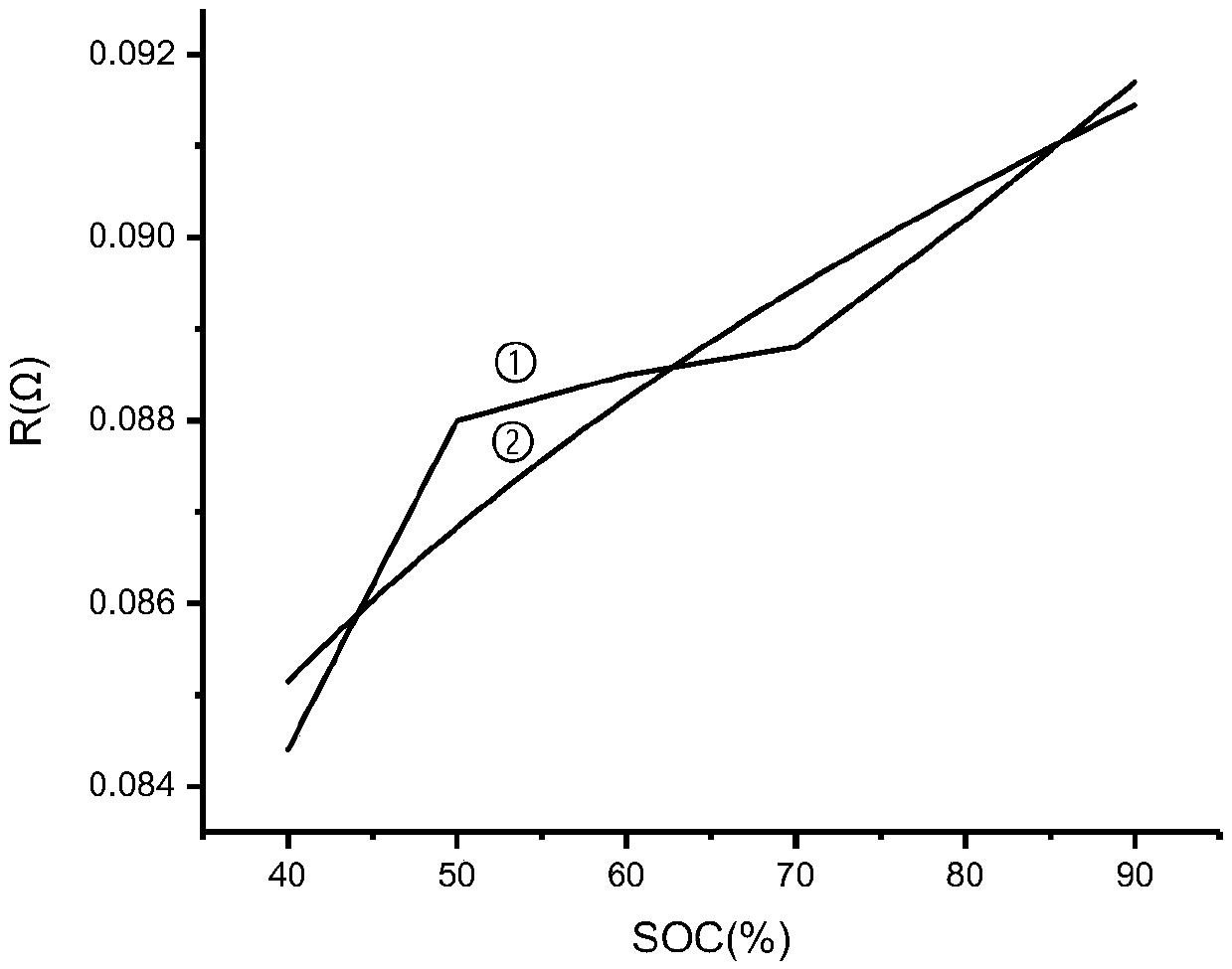

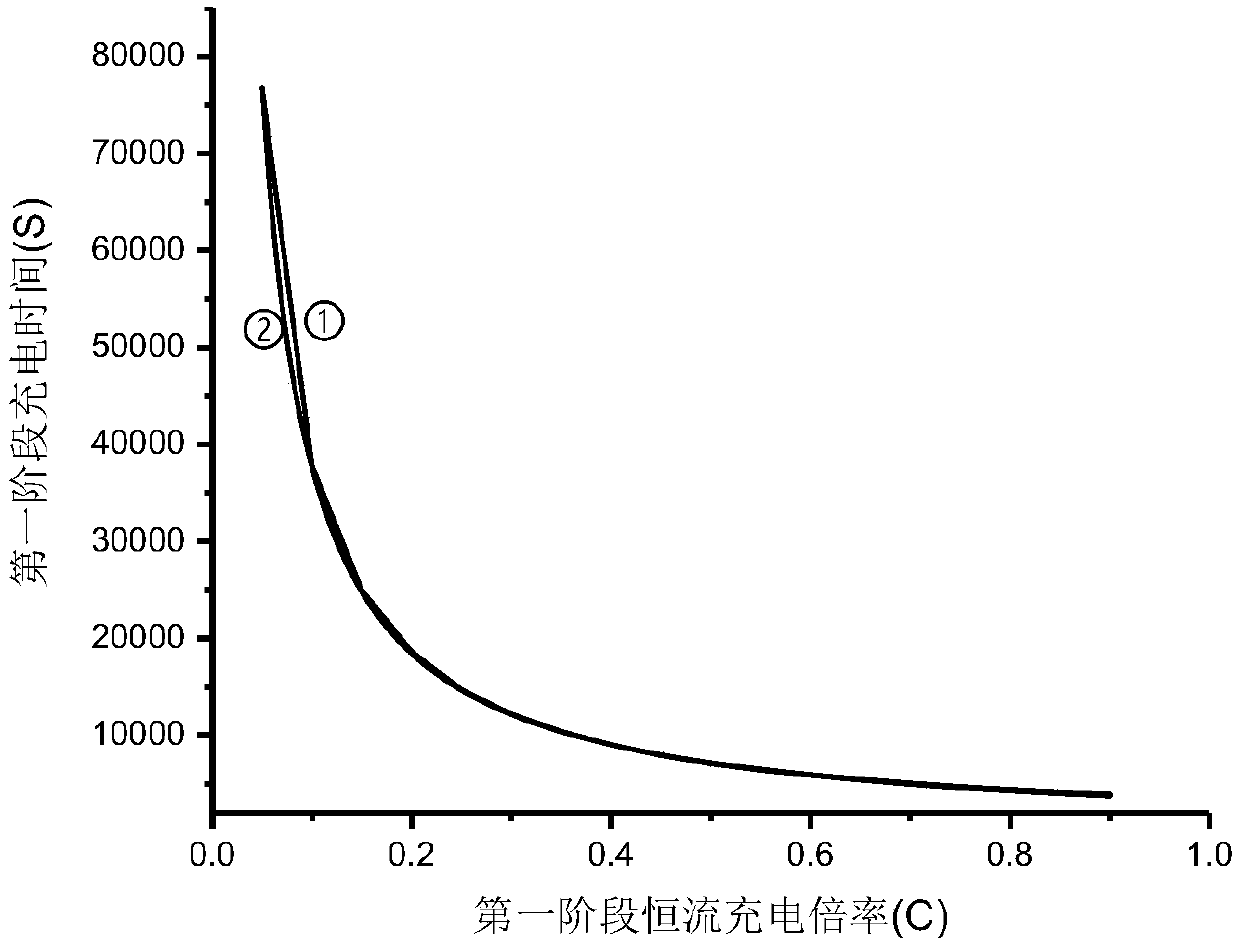

[0063] Use the first stage constant current charging rate 0.6C (1.2A), the fourth stage constant current charging rate 0.1C (0.2A), constant voltage charging time 0min; the first stage constant current charging rate 0.6C (1.2A), the second Four-stage constant current charging rate 0.3C (0.6A), constant voltage charging time 0min; first stage constant current charging rate 0.8C (1.6A), fourth stage constant current charging rate 0.1C (0.2A), constant voltage charging Time 0min; standard charging rate constant current and constant voltage charging to charge the lithium-ion battery respectively. The lithium-ion battery has a positive electrode of ternary material and a negative electrode of graphite. The rated capacity is 2Ah, and the standard charging rate is 0.5C (1A). The charging results of the four charging methods for lithium-ion batteries are as follows: Figure 4 , 5 , 6, and 7. In each figure, the curve ① represents the charging rate, the curve ② represents the chargin...

Embodiment 2

[0065] Use the first stage constant current charging rate 0.6C (1.2A), the fourth stage constant current charging rate 0.1C (0.2A), constant voltage charging time 0min; use the first stage constant current charging rate 0.6C (1.2A), The fourth stage constant current charging rate is 0.3C (0.6A), constant voltage charging time is 0min; the first stage constant current charging rate is 0.8C (1.6A), the fourth stage constant current charging rate is 0.1C (0.2A), constant voltage Charging time 0min; standard charging rate constant current constant voltage; use the first stage constant current charging rate 0.6C (1.2A), the fourth stage constant current charging rate 0.1C (0.2A), constant voltage charging time 5min; use the first stage Six charging methods are used to charge the lithium-ion battery, the lithium-ion battery has a positive electrode of three Material, the negative electrode is graphite, the rated capacity is 2Ah, and the standard charging rate is 0.5C (1A). The char...

Embodiment 3

[0067] Use the constant current charging rate of 0.6C (1.2A) in the first stage, the constant current charging rate of 0.2C (0.4A) in the fourth stage, and the constant voltage charging time of 5 minutes; the standard constant current and constant voltage is used to charge the lithium-ion battery. The positive electrode of the battery is a ternary material, the negative electrode is graphite, the rated capacity is 2Ah, and the standard charging rate is 0.5C (1A). The charging time of the former is 6452s, the charging time of the latter is 8888s, the charging SOC of the former is 98.28%, and the charging SOC of the latter is 100.14%. The SOC is obtained by dividing the actual charging capacity of the lithium-ion battery by the rated capacity. Here the SOC is greater than 100%, indicating that the charging capacity is greater than the rated capacity. Both capacity decay curves are as Figure 10 As shown, curve ① is the battery capacity decay curve of standard constant current a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com