Longitude line automatic feeding electric control system of metal netting machine

An electric control system, technology of weaving netting machine, applied in the direction of general control system, control/regulation system, computer control, etc., can solve the problems of low weaving speed, mechanical wear, inability to change the width and density of weaving net, etc. Achieve the effect of improving the weaving efficiency and fast thread take-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

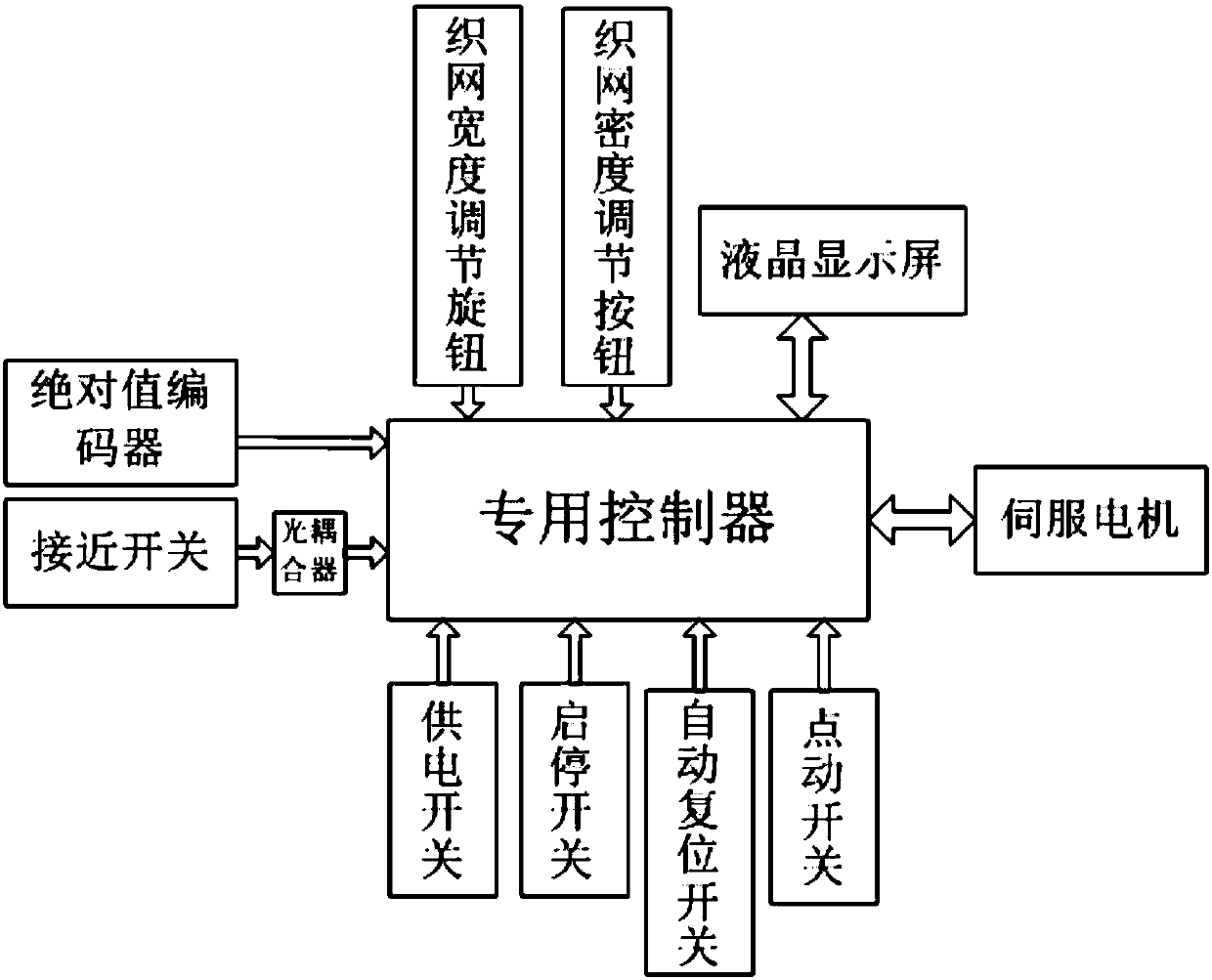

[0024] Such as figure 1 As shown, the warp automatic wire feeding electric control system of the metal net weaving machine according to the present invention includes: a special controller, a servo motor, a proximity switch, an optical coupler, a photoelectric encoder, a liquid crystal display, a power supply switch, a start-stop switch, automatic reset switch, jog switch, web width adjustment knob and web density adjustment button;

[0025] The power supply switch is respectively connected with the main controller and the external power supply, and is used for power supply and power-off of the electric control system;

[0026] The start-stop switch is connected with a dedicated controller for running and stopping the electric control system;

[0027] The proximity switch is connected with an optical coupler for confirming whether the rapier is sending the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com