Method and apparatus for detection of broken piezoelectric material of ultrasonic transducer

A piezoelectric material and ultrasonic technology, which is used in material analysis using sonic/ultrasonic/infrasonic waves, using electrical devices, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the efficiency and gain loss of ultrasonic transducers, and affect the ultrasonic process question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Example embodiments will now be described more fully with reference to the accompanying drawings.

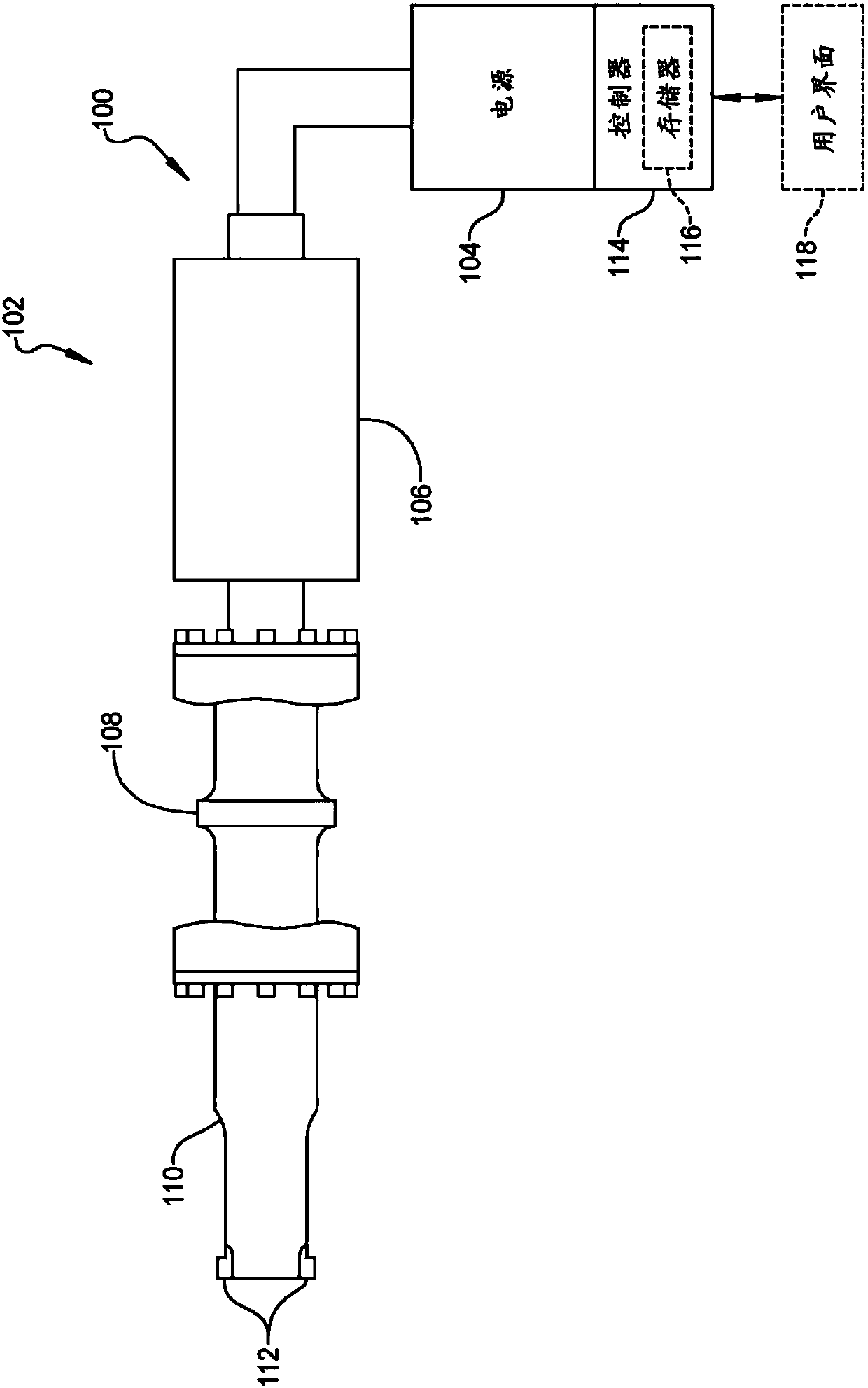

[0018] The following will refer to figure 1 The ultrasonic device 100 of the present invention is discussed, but it should be understood that the following applies to any ultrasonic device having an ultrasonic assembly powered by a power source. In this regard, it should be appreciated that the method of detecting the piezoelectric material of the ultrasonic transducer 106 according to one aspect of the present disclosure as described below differs from methods used in prior art ultrasonic devices, and figure 1 and figure 2 A statement that it is prior art does not mean that the methods described below belong to the prior art.

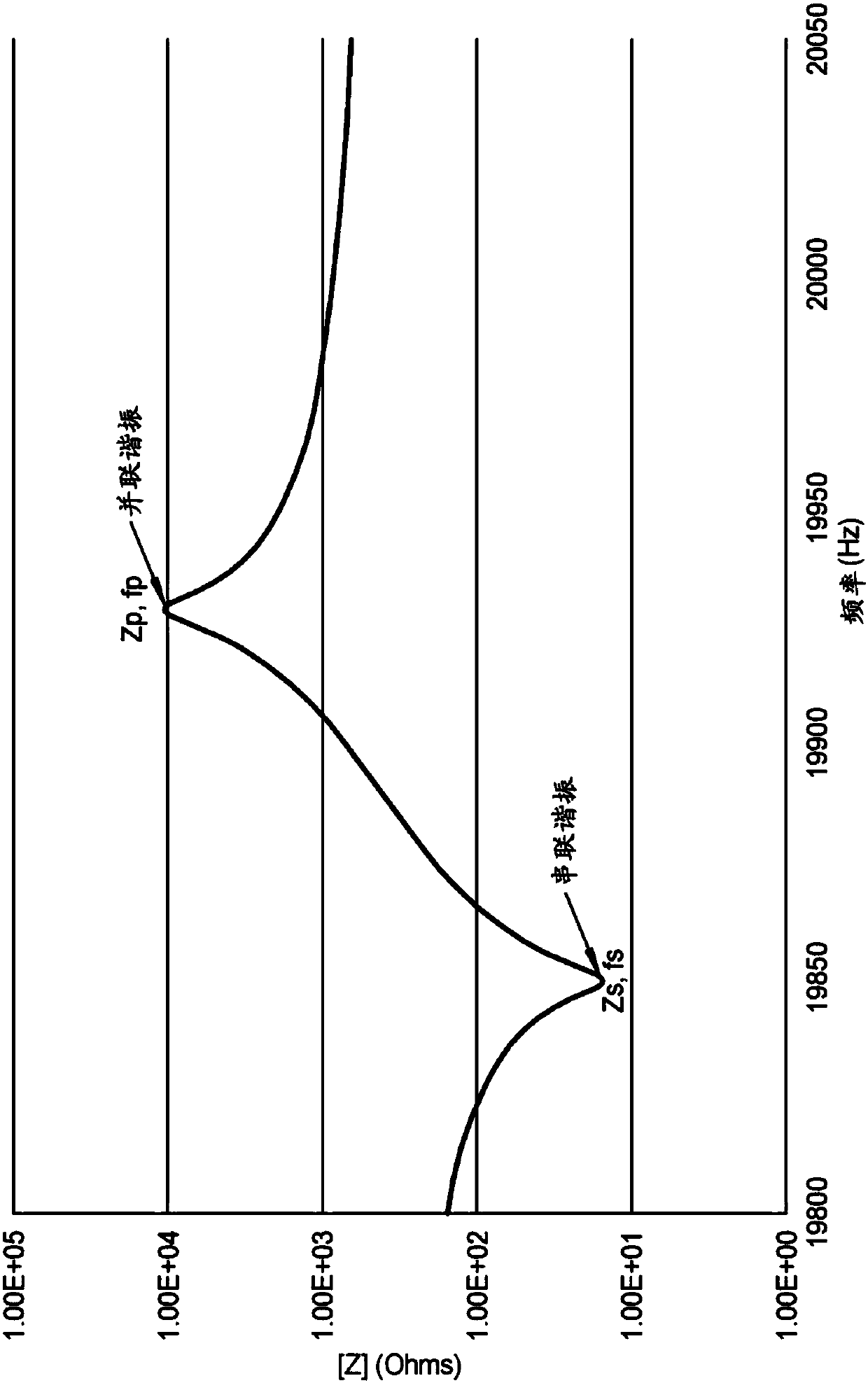

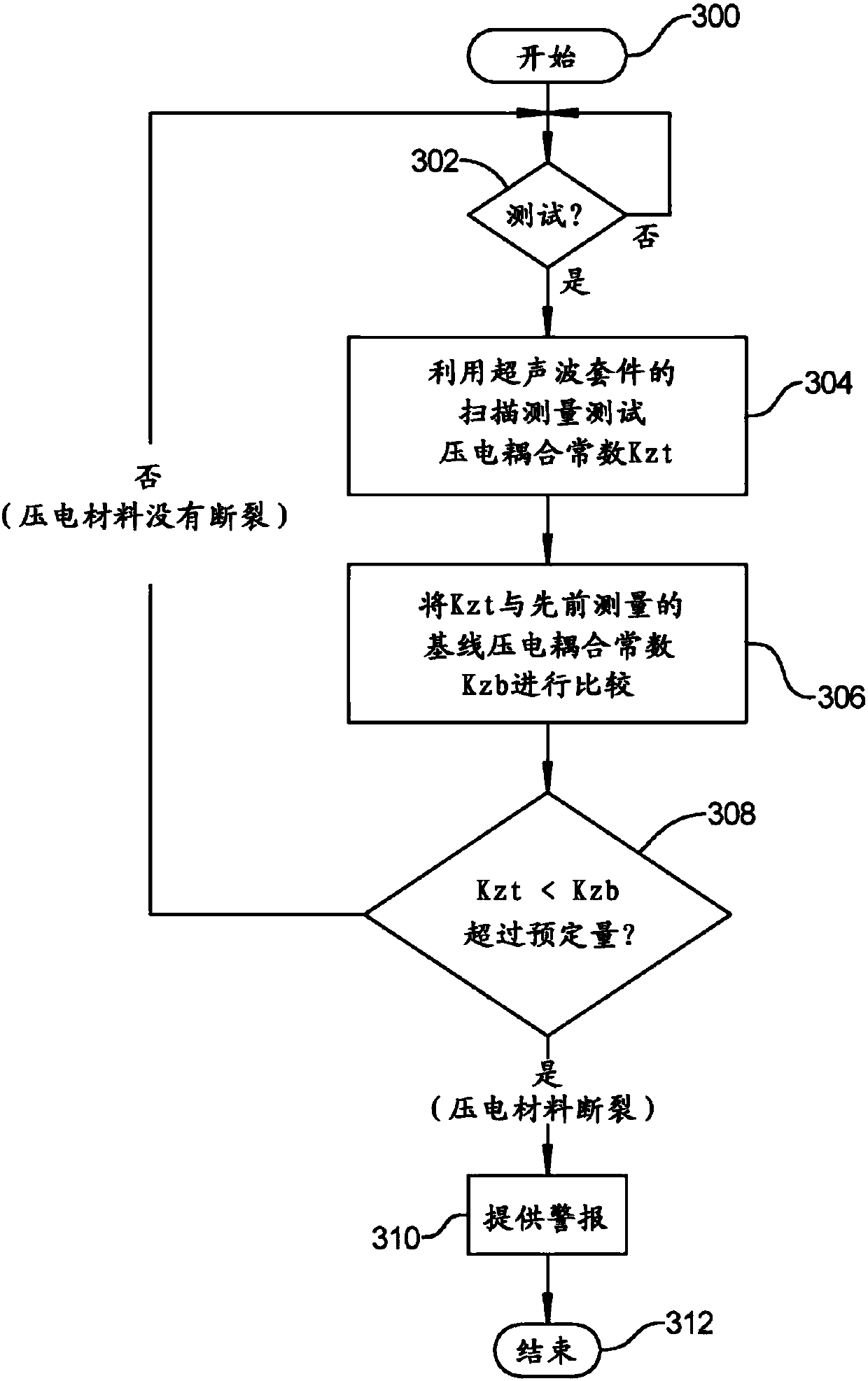

[0019] According to one aspect of the present disclosure, measuring the piezoelectric coupling coefficient K z To determine whether the piezoelectric material of the ultrasonic transducer 106 is broken. As is known in the art, the piezoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com