Washing machine with spray-rinsing function

A washing machine and washing water technology, which is applied to washing machines with containers, other washing machines, washing devices, etc., can solve the problems of entanglement and damage of clothes, and achieve the effects of simple structure, improved washing effect and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

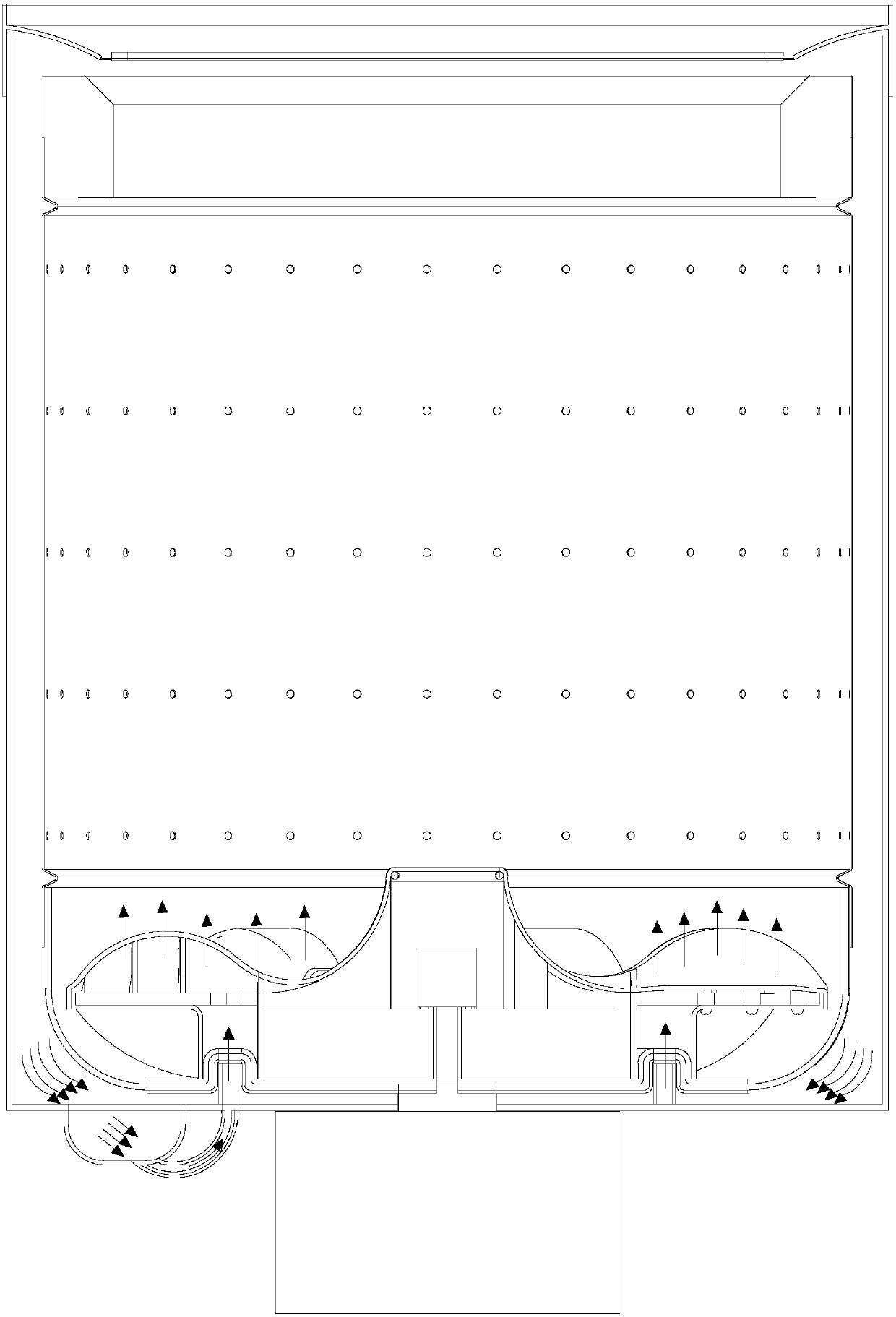

[0032] Such as image 3 with Figure 4 As shown, in this embodiment, the connecting waterway 6 is formed by an annular waterway arranged between the wave wheel 3 and the bottom of the outer barrel 4, the upper end of the annular waterway communicates with the internal waterway 13 of the wave wheel 3, and the lower end It communicates with the gap between the bottom of the inner bucket 5 and the bottom of the outer bucket 4, so that the washing water between the inner and outer buckets flows into the bottom of the inner bucket evenly through the ring-shaped connecting water channel 6; preferably, the ring-shaped connecting water channel 6 and The outer barrel 1 is coaxially arranged; further preferably, the diameter of the circumference arranged by the connecting water channel 6 is 1 / 2 of the outer circumference diameter of the outer barrel 1, so that the connecting water channel is arranged in the middle of the inner barrel, so that the water flowing in from the connecting wat...

Embodiment 2

[0040] Such as Figure 3 to Figure 6 As shown, in this embodiment, an upper flange 19 and a lower flange 20 are respectively provided on the inner side and the outer side of the inner bucket bottom 5 to improve the structural strength of the inner bucket bottom and make the inner bucket bottom more resistant to torsion. The upper flange is clamped between the bottom of the inner barrel and the pulsator, and the lower flange is installed between the bottom of the inner barrel and the bottom of the outer barrel, so that during the rotation of the inner barrel and / or the pulsator, the flange plate bears The wear and tear caused by it increases the service life of the washing machine.

[0041] At the same time, in this embodiment, in order to be applicable to the washing machine for spray-float washing described in the above embodiment, compared with Embodiment 1, the following improvements are made: the upper flange 19 is provided with an opening structure 12 and a convex The fi...

Embodiment 3

[0047] Such as Figure 3 to Figure 5 As shown, in this embodiment, the hollow part of the groove structure 10 provided on the bottom of the outer tub 4 communicates with the gap between the inner and outer tubs through the connecting pipe 8 provided with the water pump 9, so that the washing water between the inner and outer tubs passes through the gap between the inner and outer tubs. The connecting pipe 8 flows into the groove structure 10 .

[0048] Preferably, the bottom of the outer tub 4 is provided with a downwardly recessed water supply tank 7, the water supply tank 7 is arranged between the groove structure 10 and the outer periphery of the outer tub bottom 4, and the bottom of the water supply tank 7 passes through the connecting pipe 8 It communicates with the bottom of the hollow part of the groove structure 10, and a water pump 9 is provided in the water supply tank 7 to provide power for the washing water between the inner and outer tubs to the connecting pipe 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com