High magnetic permeability, high frequency and high impedance soft magnetic material and preparation method thereof

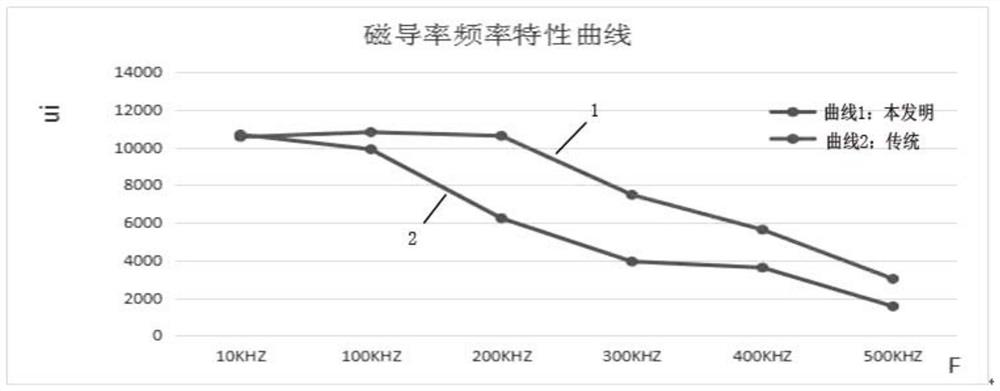

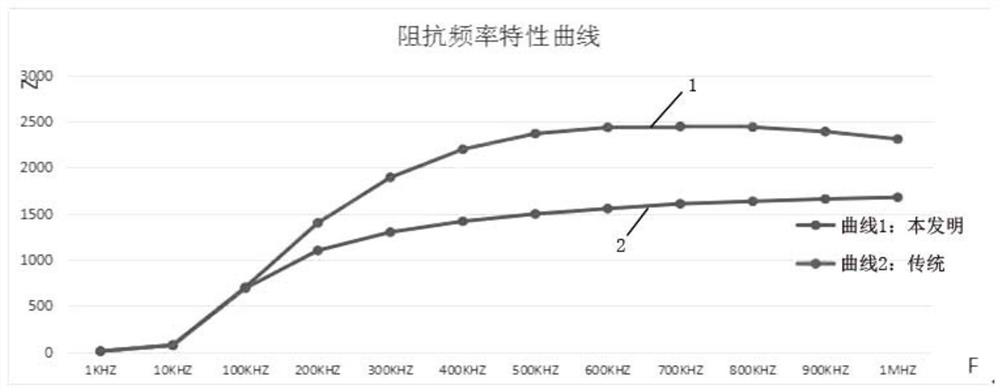

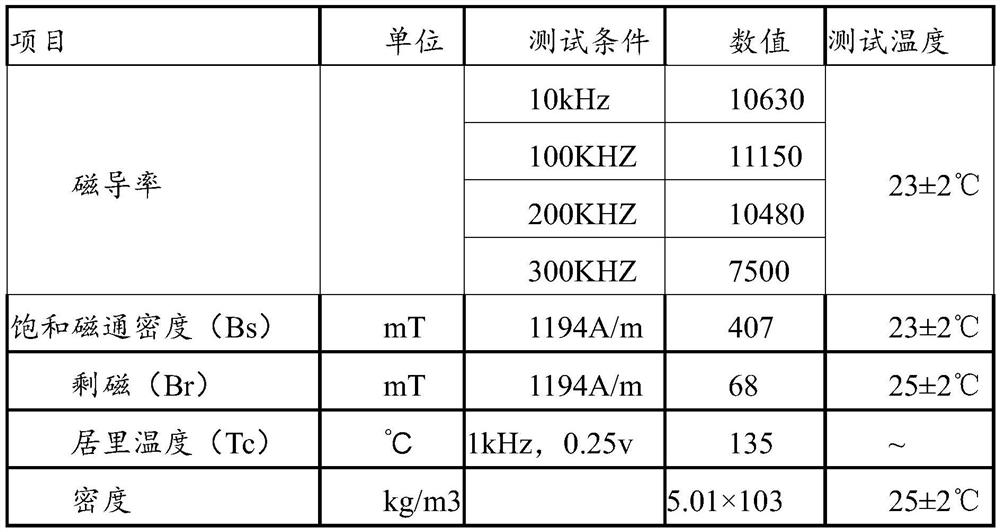

A technology of soft magnetic materials and high magnetic permeability, which is applied in the field of high-frequency high-impedance soft magnetic materials and high magnetic permeability, can solve the problems of high-frequency impedance characteristics, large magnetic core volume, and high cost, and achieve High-frequency filtering effect is good, the number of coil turns is small, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] Correspondingly, the present invention also provides a method for preparing a soft magnetic material with high magnetic permeability, high frequency and high impedance characteristics, including:

[0052] Step A: Proportion the content of main ingredients, then add deionized water to the sand mill for mixing and crushing, and add PVA solution after recirculation mixing;

[0053] In the step A: the crushing lasts for 25-35 minutes, and the circular mixing lasts for 8-15 minutes, which can improve the crushing effect, optimize the main component process and physical and chemical properties.

[0054] Step B: putting the crushed and mixed main ingredients into a pre-burning furnace for pre-burning;

[0055] In the step B: the temperature in the pre-sintering furnace is controlled at 850-950° C., and the pre-sintering furnace is kept warm for 2.5-3.5 hours, which can further optimize the main component process and physical and chemical properties, and improve the crystal str...

Embodiment 1

[0068] 1. Ingredients:

[0069] Weigh Fe 2 o 3 :51.5mo1%; ZnO:21.3mo1%; MnO:27.2mo1%, the three raw materials are Taiwan Zhongganghong, Hunan Jinrui Sanmeng Tetroxide, Shanghai Jinghua Zinc Oxide, and add 15wt% ionized water into the sand mill Mixing and crushing were carried out, the crushing was carried out for 45 minutes, and after 10 minutes of circulating mixing, 1.4 wt% PVA solution was added for spray granulation.

[0070] 2. Pre-burning:

[0071] Put the sprayed material into the pre-fired furnace, and heat it at 860°C for 3 hours for pre-fired.

[0072] 3. Secondary sanding:

[0073] Add the following auxiliary component Nb according to the weight percentage of calcined material in calcined material 2 o 5 0.020wt%, CaO 0.04wt%, MoO 3 0.03wt%, V 2 o 5 is 0.02wt%, and ZrO is 0.02wt%.

[0074] Then put the powder into a sand mill and add 15wt% deionized water for secondary sand milling. The sand milling time is 60 minutes, and the particle size of the powder is...

Embodiment 2

[0084] 1. Ingredients:

[0085] Weigh Fe 2 o 3: 51.35mol%; ZnO: 21.3mol%; MnO: 27.45mol%, the three raw materials are Korean EG Iron Red, Hunan Jinrui Sanmeng Tetroxide, Shanghai Jinghua Zinc Oxide, and add 15wt% ionized water into the sand mill Mixing and crushing were carried out, the crushing was carried out for 45 minutes, and after 10 minutes of circulating mixing, 1.4 wt% PVA solution was added for spray granulation.

[0086] 2. Pre-burning:

[0087] Put the sprayed material into the pre-fired furnace, and heat it at 860°C for 3 hours for pre-fired.

[0088] 3. Secondary sanding:

[0089] Add the following auxiliary component Nb according to the weight percentage of calcined material in calcined material 2 o 5 0.020wt%, CaO 0.04wt%, MoO 3 0.03wt%, V 2 o 5 is 0.02wt%, and ZrO is 0.02wt%. Then put the powder into a sand mill and add 15wt% deionized water for secondary sand milling, the sand milling time is 60 minutes, and the particle size of the powder is contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com