Elastic piece type foamed plastic primary sealing device for floating roof storage tank and installation method of elastic piece type foamed plastic primary sealing device

A foamed plastic, floating roof storage tank technology, used in packaging, transportation and packaging, containers and other directions, can solve the problems of inability to seal, seal gaps, and seal the structure of lightning discharge points, to eliminate oil and gas space and reduce fire accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

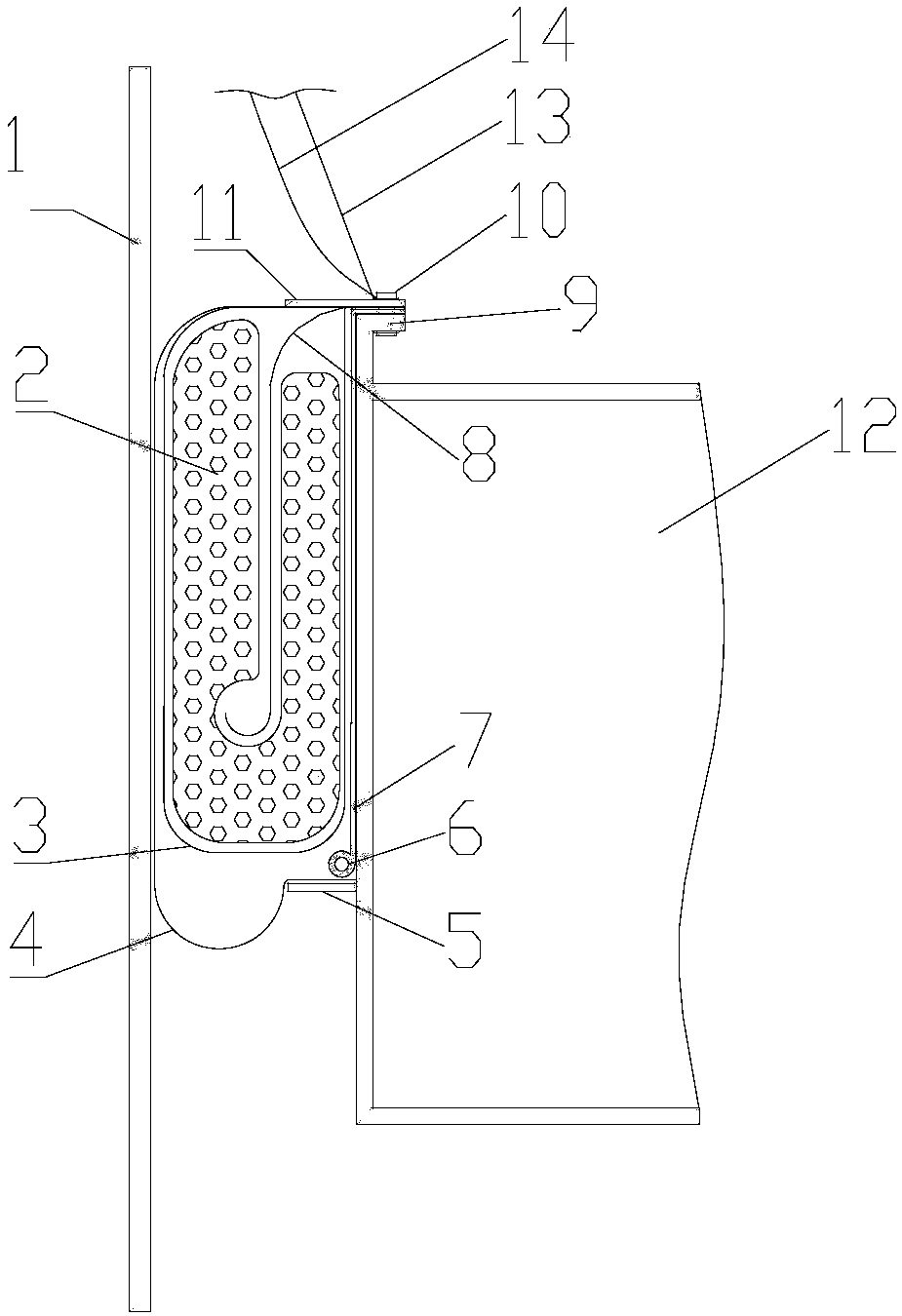

[0038] With reference to the accompanying drawings, a shrapnel-type foam primary sealing device for a floating roof storage tank includes an outer rubber belt 4, one side of the outer rubber belt 4 is in contact with the edge plate 9 of the floating plate and fixed. An inner rubber belt 3 is arranged inside the outer rubber belt 4, and an elastic sponge 2 is wrapped inside the inner rubber belt 3, and an elastic steel sheet 8 providing elastic force toward the tank wall 1 is clamped in the middle of the elastic sponge 2 , the elastic change of the elastic steel sheet 8 plays a very good role in compensating the sealing performance of the elastic sponge 2 . That is, when the edge gap of the floating disc changes greatly, the elastic steel sheet 8 can bounce the inner rubber belt 3 to compensate for the insufficient deformation of the elastic sponge 2 . According to the deformation of the tank wall 1, the elasticity and shape of the elastic steel sheet 8 can be adjusted to meet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com