Galvanized high-strength steel resistance spot welding method with good joint performance

A resistance spot welding and high-strength steel technology, applied in resistance welding equipment, welding power sources, welding power sources, etc., can solve the problems of no application, joint interface fracture, LME cracks, etc., to suppress the crack problem, improve the plasticity and quality of solder joints reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

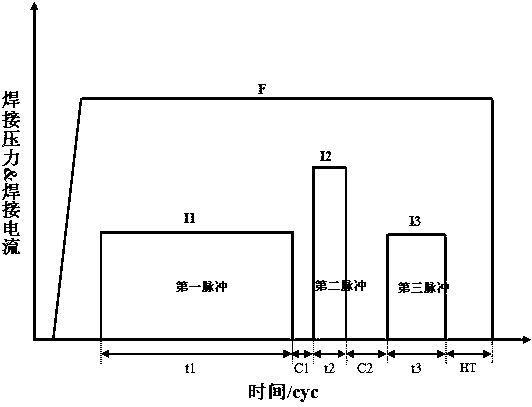

[0066] A 1.6mm galvanized high-strength steel (see Table 2 for mechanical properties and composition) was spot-welded by three spot welding processes of No. 1, No. 2 and No. 3. Compare and evaluate the LME crack generation of the solder joints and the fracture mode of the solder joints during the ring breakage test. The characteristics and test results of the three spot welding processes are shown in Table 3.

[0067] Table 2 Composition and mechanical properties of a galvanized high-strength steel

[0068]

[0069]

[0070] Table 3 Characteristics and results of No. 1, No. 2 and No. 3 spot welding processes

[0071]

[0072] The detailed results are as follows:

[0073] 1. Results of No. 1 spot welding process:

[0074] The details of No. 1 spot welding process are shown in Table 4:

[0075] Table 4 No. 1 spot welding process

[0076]

[0077] Note: I in the table 1 =I 2 =I 3

[0078] Through metallographic testing, severe liquid metal embrittlement (LME)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com