Mechanical equipment used for forging and pressing

A technology of mechanical equipment and punching machines, applied in forging presses, forging presses, forging/pressing/hammering machinery, etc., can solve problems such as inaccurate feeding process, lack of built-in buffer and shock absorption functions, and low degree of mechanization , to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

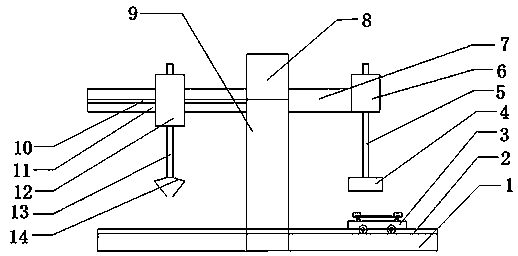

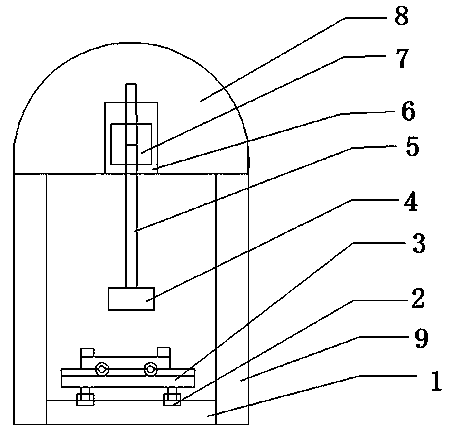

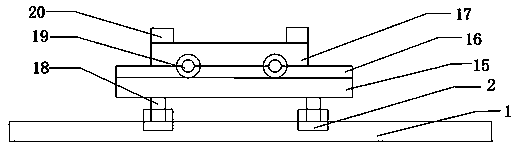

[0012] Such as Figure 1-3 As shown, a kind of mechanical equipment for forging, it includes base 1, support frame 9, beam A7, beam B11, transmission box 8, stamping machine 6, pick-up machine 12, mobile trolley 3, described base 1 There are two first guide rails 2 installed in parallel on it, the first guide rail 2 is installed in the center of the base 1, and the mobile trolley 3 is installed on the first guide rail 2; the support frame 9 is arranged on both sides of the middle of the base 1, and the riveted base Seat 1, a transmission box 8 is installed on the top of the support frame 9, a crossbeam A7 is arranged on the right side of the transmission box 8, and the right end of the crossbeam A7 is riveted with a punching machine 6; , the picker 12 is installed on the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com