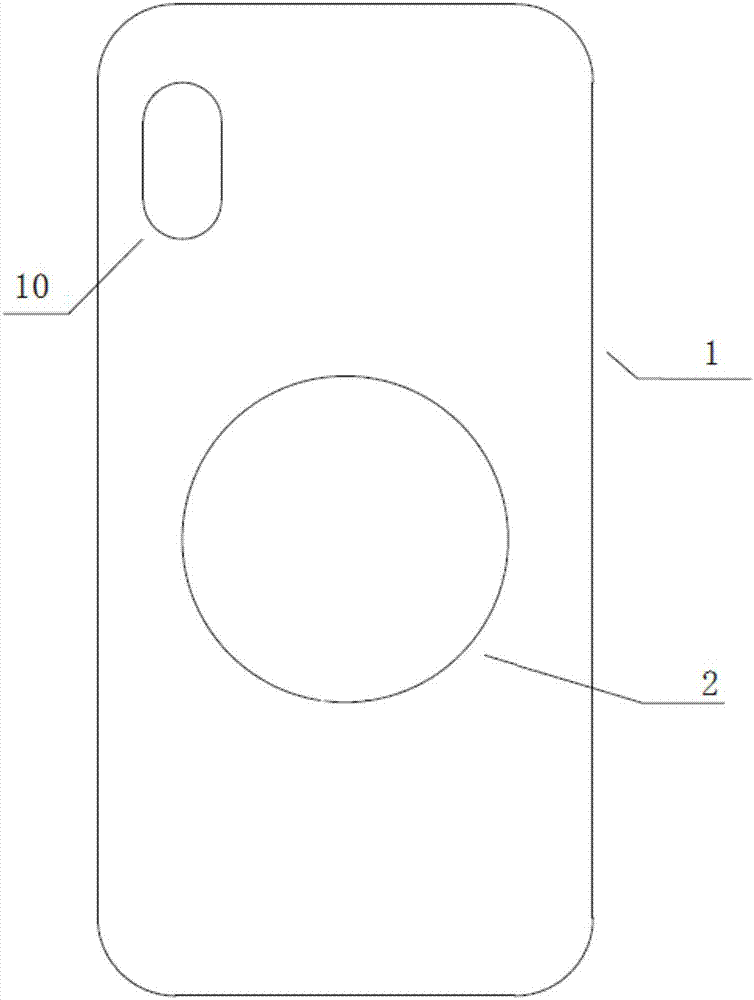

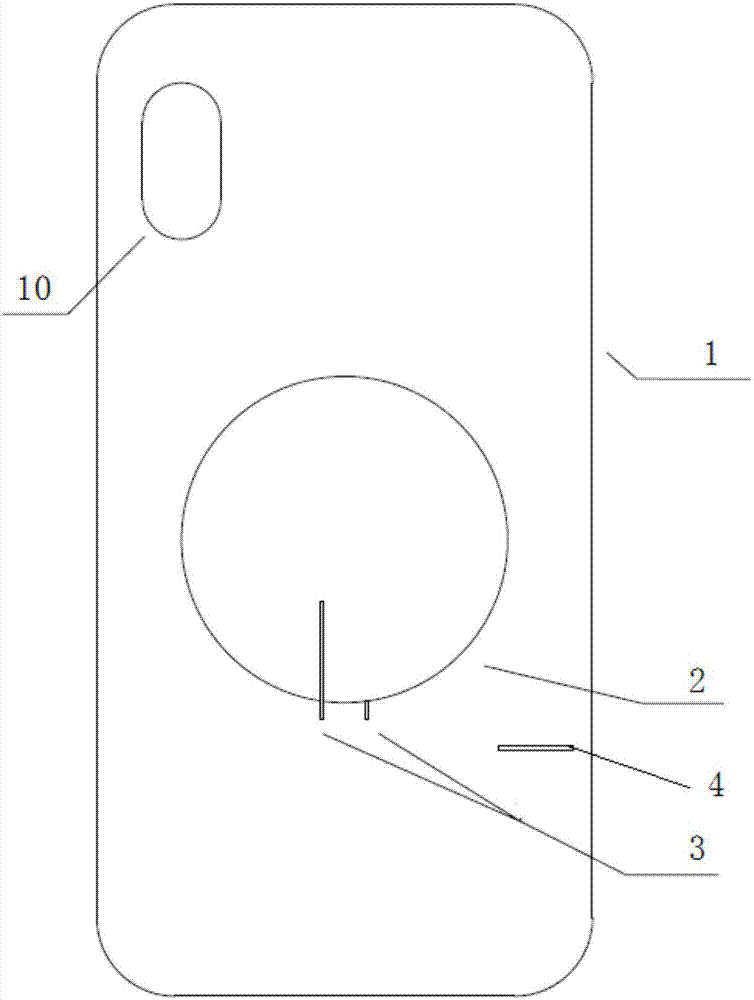

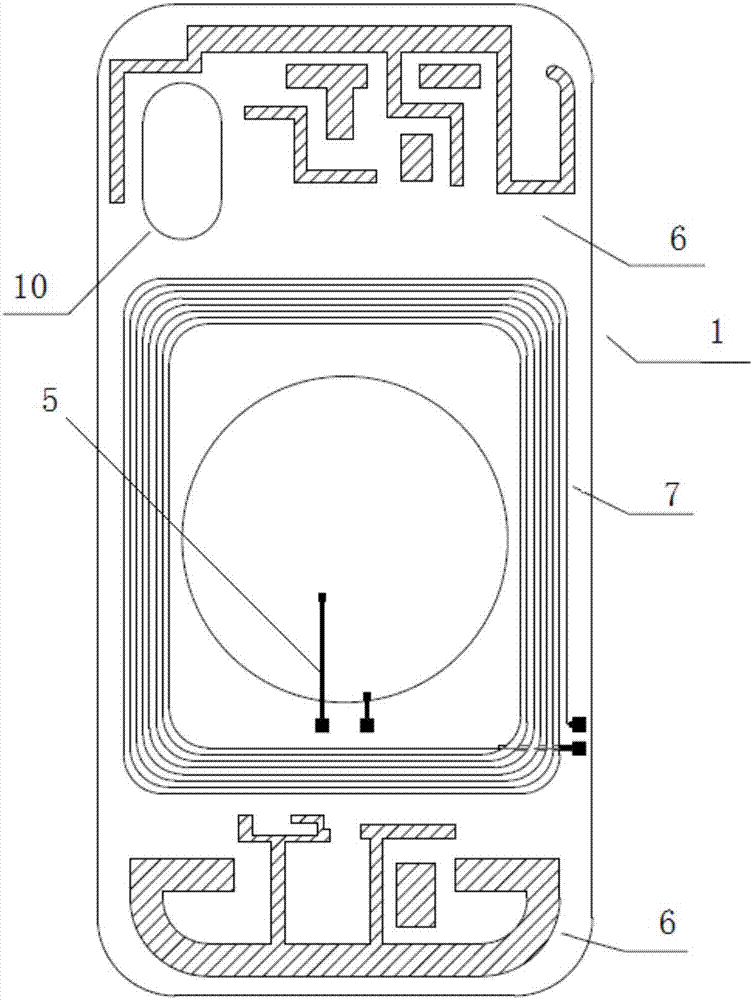

Ceramic back cover for electronic equipment, and electronic equipment with same

A technology of electronic equipment and ceramics, which is applied in the field of shell structure and its components, can solve the problem of wireless charging efficiency is not ideal, and achieve the effect of miniaturization, high heat dissipation efficiency, and overcome the internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0056] Take a metal wire with the same wire diameter (0.10mm) and wind it 13 times to make a coil. In this example, the ceramic back cover of the present invention is used. Compared with the traditional method of bonding the wireless charging RX coil and the magnetic plate together and fixing it on the battery back cover, in terms of power output, the input voltage and output voltage are set to 12V, and at 0.1A, the coil in the example of the present invention The efficiency of the coil is 58%, and the efficiency of the traditional method coil is 45%; at 0.5A, the efficiency of the coil in the example of the present invention is 81%, and the efficiency of the traditional method coil is 75%; at 1.0A, the coil in the example of the present invention The efficiency of the coil is 86%, and the efficiency of the traditional method coil is 78%. It can be seen from the data that the wireless charging efficiency of the coil corresponding to the example of the present invention is obvi...

example 2

[0058] Also take a metal wire with the same wire diameter (0.10mm) and wind it 12 times to make a coil. In this example, the ceramic back cover of the present invention is used. Compared with the traditional method of bonding the wireless charging RX coil and the magnetic plate together and fixing it on the battery back cover, in terms of power output, the input voltage and output voltage are set to 12V, and at 0.1A, the coil in the example of the present invention The efficiency of the coil is 54%, and the efficiency of the traditional method coil is 41%; at 0.5A, the efficiency of the coil in the example of the present invention is 78%, and the efficiency of the traditional method coil is 70%; at 1.0A, the coil in the example of the present invention The efficiency of the coil is 82%, and the efficiency of the traditional method coil is 74%. It can be seen from the data that the wireless charging efficiency of the coil corresponding to the example of the present invention is...

example 3

[0060] Also take a metal wire with the same wire diameter (0.10mm) and wind it 10 times to make a coil. In this example, the ceramic back cover of the present invention is used. Compared with the traditional method of bonding the wireless charging RX coil and the magnetic plate together and fixing it on the battery back cover, in terms of power output, the input voltage and output voltage are set to 12V, and at 0.1A, the coil in the example of the present invention The efficiency of the coil is 50%, and the efficiency of the traditional method coil is 38%; at 0.5A, the efficiency of the coil in the example of the present invention is 72%, and the efficiency of the traditional method coil is 67%; at 1.0A, the coil in the example of the present invention The efficiency of the coil is 78%, and the efficiency of the traditional method coil is 70%. It can be seen from the data that the wireless charging efficiency of the coil corresponding to the example of the present invention is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com