Flexible display device and manufacturing method thereof

A flexible display and device technology, applied in the direction of instruments, nonlinear optics, identification devices, etc., can solve problems that affect the stability of service life, easy to form cracks, film shedding, etc., achieve excellent flexible display effect, increase bending resistance, The effect of reducing the radius of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

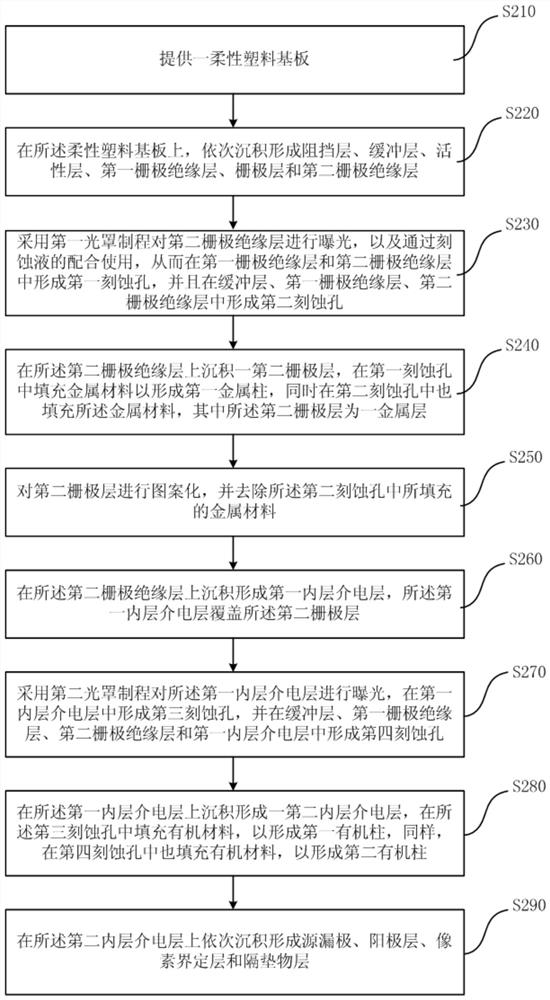

[0016] The specific implementation of the flexible display device provided by the present invention and the preparation method for improving the film stress in the flexible display device will be described in detail below with reference to the accompanying drawings.

[0017] In the prior art, there are many inorganic layers in the LTPS structure, and the difference in film stress between the inorganic layers will cause the film to fall off and the substrate to warp, thereby affecting the service life and stability. At the same time, the thick organic layer Cracks are easy to form after countless times of bending, thereby destroying the device structure.

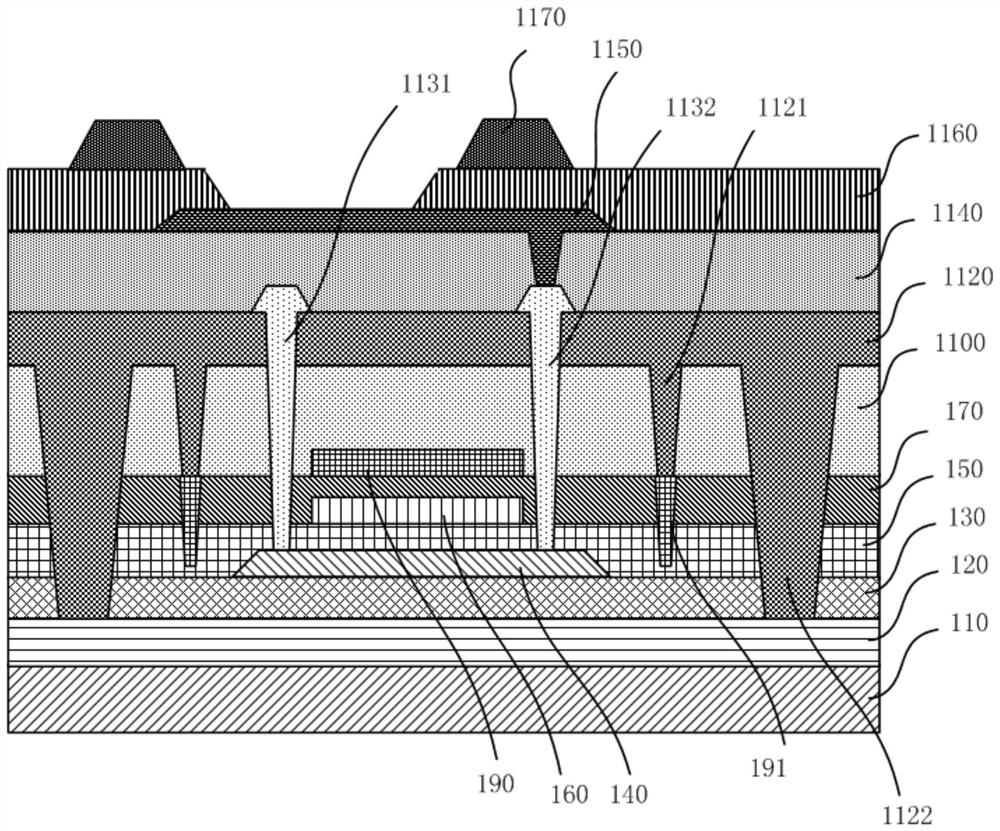

[0018] Therefore, the present invention proposes that introducing an isolation layer into the original structure can reduce the film stress. Further, the present invention provides a flexible display device, which includes a flexible plastic substrate 110, on which a first gate insulating layer 150, a second gate insulating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com