Shield tunneling machine muddy water tank soil mud pressure sensor replacing device and method for replacing same

A technology of pressure sensor and mud tank, which is applied in the direction of measuring device, earthwork drilling and measuring fluid pressure, etc. It can solve the problems of prolonging the progress of excavation construction, shutting down the shield machine for maintenance, and manually entering the mud tank, so as to reduce maintenance time, Guarantee soil and mud leakage and improve the effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

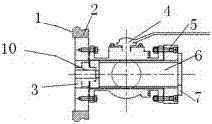

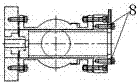

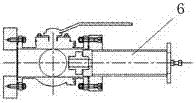

[0021] Refer to attached Figure 1-4 , a device for replacing soil and mud pressure sensors in the mud tank of a shield machine, which includes a valve front flange 2 arranged on the shield wall 1, the two can be connected by welding, and the valve front flange and the shield wall are welded, which is convenient The ball valve is installed and fixed. There is a middle hole 3 in the middle of the front flange of the valve. A ball valve 4 is provided at the right end of the front flange of the valve. The inner cylinder is installed in the ball valve, and can seal and slide in the valve core of the ball valve. One end of the fixed inner cylinder of the sensor is connected to the rear flange of the valve, and the other end of the fixed inner cylinder of the sensor is connected to the soil and mud pressure sensor 10. The rear flange of the valve can be Drive the sensor to fix the inner cylinder to move back and forth.

[0022] Preferably, the right end of the sensor fixing inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com