Benchmarking test tool of multiple temperature sensors and test method thereof

A temperature sensor and testing tooling technology, applied in thermometer testing/calibration, thermometers, measuring devices, etc., can solve the problems of poor reproducibility of temperature sensors and interference with technicians' judgment, and achieve strong reproducibility and benchmarking test results Reliable, effect of reducing measurement deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

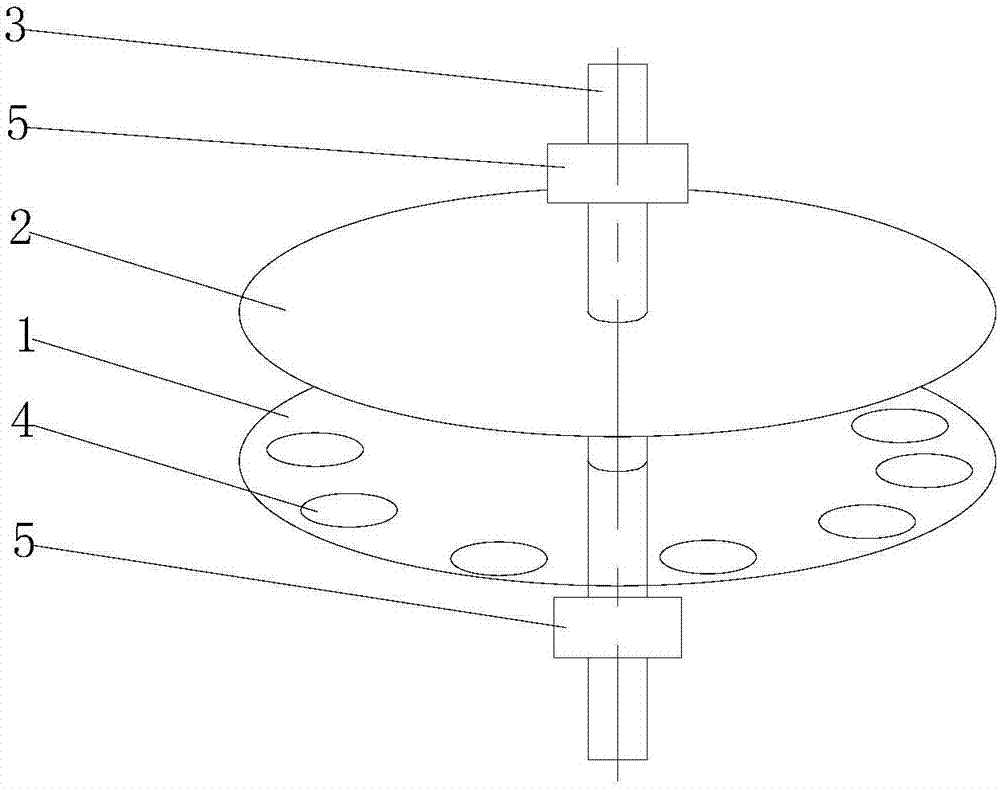

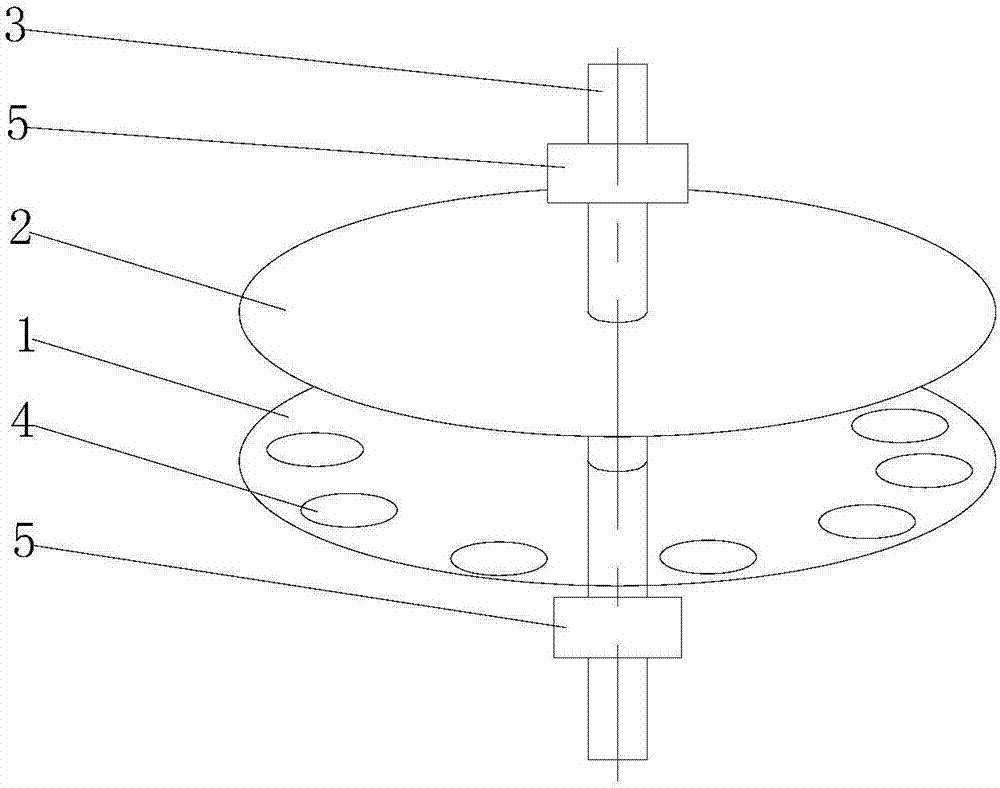

[0023] refer to figure 1 , a multiple temperature sensor benchmarking test fixture, including a shelf 1, a cover plate 2 that is located above the shelf 1 and can move up and down relative to the shelf 1 to press down the multiple temperature sensors, and passes through the shelf 1 and the cover. The connecting rod 3 of the plate 2, the shelf 1 and the cover plate 2 are made of high temperature and corrosion resistant materials, which have high stability during use and long service life. The shelf 1 is provided with multiple mounting holes 4 for installing temperature sensors , the two ends of the connecting rod 3 are respectively provided with fasteners 5 for locking the shelf 1 and the cover 2, the shelf 1 and the cover 2 are coaxially arranged, and the axis of the connecting rod 3 is aligned with the shelf 1 and the cover 2 The axis coincides, and multiple temperature sensors are pressed and fixed on the shelf 1 through the cover plate 2, which can ensure that the probes of...

Embodiment 2

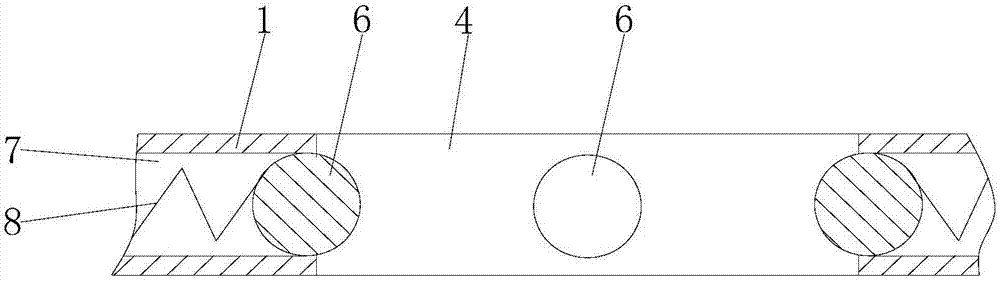

[0026] refer to figure 2 The shelf 1 is provided with an adjustment mechanism for adjusting the diameter of the installation hole 4. The adjustment mechanism includes a marble 6 embedded in the inner wall of the installation hole 4, an accommodation chamber 7 extending from the inner wall of the installation hole 4 to the outside of the shelf 1, and a housing located in the accommodation chamber. The spring 8 that connects the shelf 1 and the marble 6 in 7, when the cover plate 2 presses down the temperature sensor and squeezes the marble 6 to the inner wall, the effective aperture of the installation hole 4 will increase, which can fit within a certain range of outer diameter The unique temperature sensor effectively improves the scope of application of the tooling.

[0027] A benchmarking test method for multiple temperature sensors. First, multiple temperature sensors are installed in the installation holes 4 on the shelf 1, and then the multiple temperature sensors are si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com