Method for constructing reinforced concrete combined beam in under-beam beam transporting mode

A technology of steel-concrete composite beams and beam transportation, which is applied in bridges, bridge materials, bridge construction, etc. It can solve the problems of material waste, avoid increasing costs, improve stress, and simple construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Taking the continuous composite box girder erecting 5*30m as an example below, the construction method of the present invention is described in more detail:

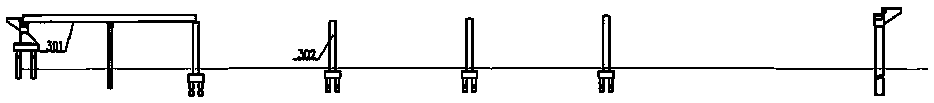

[0032] In the first step, when the construction reaches the bridge span, at first the foundation 301 and the bridge pier 302 are constructed, as figure 1 ;

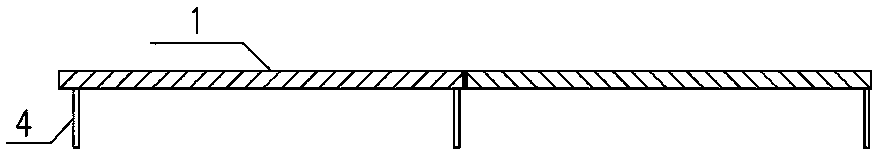

[0033] In the second step, according to the design requirements, the steel beam unit 1 for each hole is prefabricated, such as Figure 11 ;

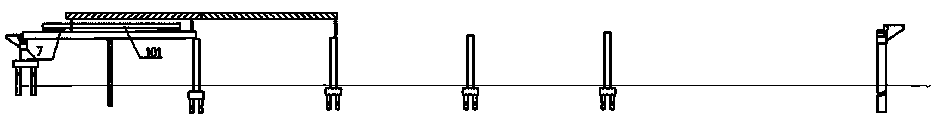

[0034] Assembling and hoisting equipment: Take two sets of prefabricated (four pieces) steel girder units 1, weld the two steel girder units along the bridge direction into one, and connect the two steel girder units across the bridge direction through the steel truss 2 in the middle (The top of the steel truss 2 is screwed to the flange of the steel beam unit 1, and the bottom of the steel truss 2 is connected to the horizontally welded connecting web 1.1 at the lower part of the oblique web of the steel beam unit);...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com