Water-repellent finishing liquid, partially water-repellent fabric and preparation method thereof

A water-repellent finishing liquid and local water-repellent technology, applied in fiber treatment, liquid repellent fibers, textiles and papermaking, etc., can solve the problem of surface not drying when wet with liquid, improve comfort and improve product quality performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

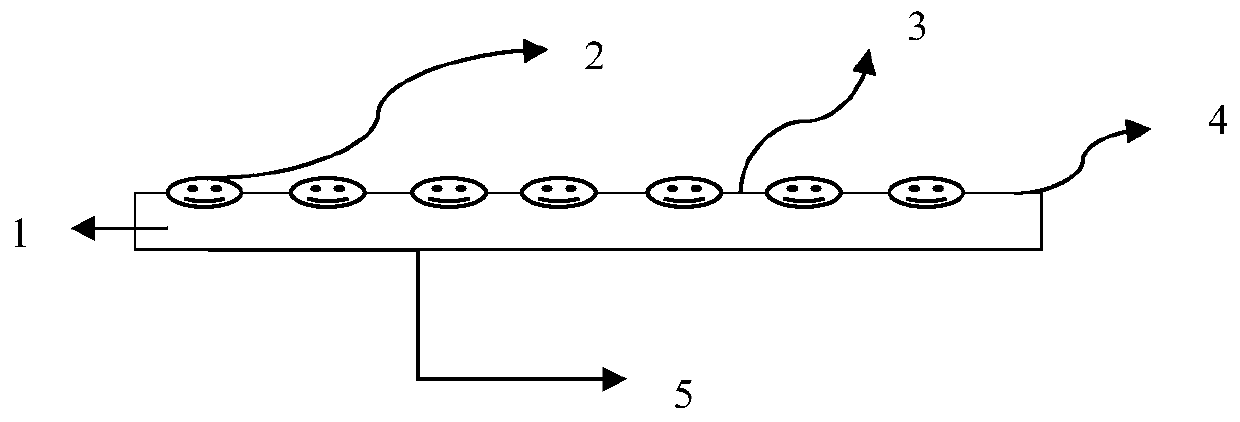

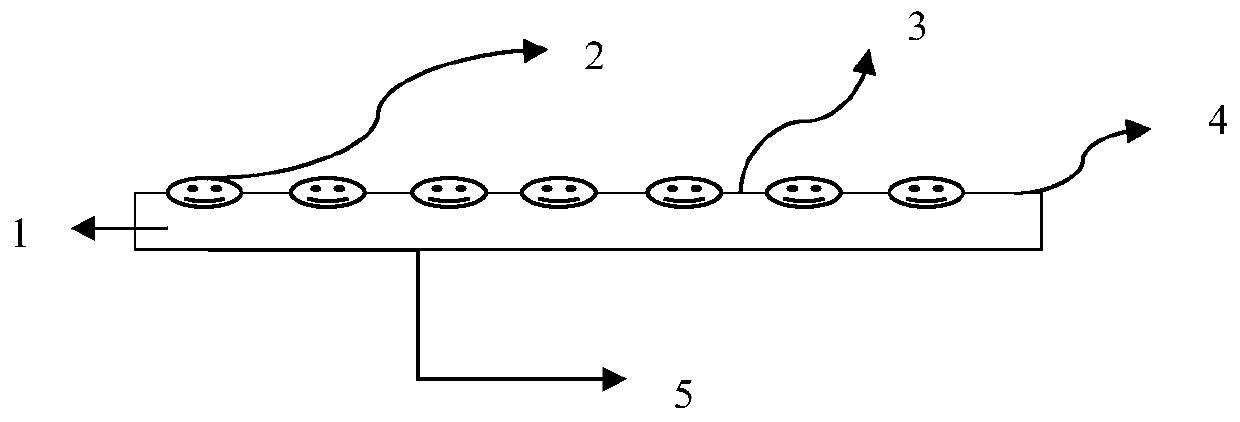

Image

Examples

Embodiment 1

[0054] Embodiment 1: produce 30g / m 2 Cotton partially water-repellent spunlace fabric

[0055] Pure cotton fiber → carding → spunlace → local water repellent finishing → drying → coiling → inspection and cutting.

[0056] The water-repellent finishing liquid is made by mixing fluoride water-repellent agent, thickener and water.

[0057] The pure cotton spunlace cloth can be straight-laid spunlace cloth, cross-laid spunlace cloth, dry cloth, or wet cloth; this test is a cross-laid 35g pure cotton dry cloth.

[0058] The weight percentages added are

[0059] Fluoride water repellent FC3410 (Guangzhou Huayu Chemical Co., Ltd.) 3%;

[0060] Water 93.9%;

[0061] Thickener PTF (Huntsman Chemical) 3%;

[0062] Concentration 18.58wt% ammoniacal liquor 0.1%.

[0063] Viscosity testing shows that the viscosity of the water-repellent finishing liquid of this embodiment is 2100mpa.s.

[0064] In the batching tank, according to the order of water→fluoride→thickener→ammonia water, add...

Embodiment 2

[0089] Embodiment 2: produce 15g / m 2 Partially water-repellent SS spunbond non-woven fabric is compared with ordinary hydrophilic SS.

[0090] SS spunbonded non-woven fabric unwinding → local water repellent finishing → drying → coiling → inspection and cutting.

[0091] The water-repellent finishing liquid is made by mixing fluoride water-repellent agent, thickener, hydrophilic agent and water.

[0092] The weight percentages added are

[0093] Fluoride water repellent E600 (Japan Asahi Glass Chemicals) 1.5%;

[0094] Water 93.4%;

[0095] Antistatic agent TY (American Stepan Chemical) 0.2%;

[0096] Penetrant JFC (Guangzhou New Huahong Chemical) 1.5%;

[0097] Thickener PTF 3.5%;

[0098] 0.2% ammonia water with a concentration of 18.58%;

[0099] Viscosity testing shows that the viscosity of the water-repellent finishing liquid of this embodiment is 2800mpa.s.

[0100] In the batching tank, follow the order of water→fluoride→antistatic agent→penetrating agent→thicke...

Embodiment 3

[0115] Embodiment 3: produce 30g / m 2 Cotton partially water-repellent spunlace fabric

[0116] Pure cotton fiber → carding → spunlace → local water repellent finishing → drying → coiling → inspection and cutting.

[0117] The water-repellent finishing liquid is made by mixing fluoride water-repellent agent, thickener and water.

[0118] Pure cotton spunlace cloth can be straight-laid spunlace cloth, crossed spunlace cloth, dry cloth, or wet cloth; this test uses 35g straight-laid pure cotton spunlace cloth wet cloth.

[0119] The weight percentages added are

[0120] Fluoride water repellent FC3410 (Guangzhou Huayu Chemical Co., Ltd.) 1.5%;

[0121] Water 94.2%;

[0122] Thickener PTF (Huntsman Chemical) 4.0%;

[0123] Concentration 18.58% ammonia water 0.3%.

[0124] Viscosity testing shows that the viscosity of the water-repellent finishing solution of this embodiment is 2600mpa.s.

[0125] In the batching tank, according to the order of water→fluoride→thickener→ammon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com