Water-repellent finishing liquid, partial water-repellent fabric and preparation method thereof

A water-repellent finishing liquid and partial water-repellent technology, which is applied in fiber treatment, liquid-repellent fibers, textiles and papermaking, etc., can solve the problems of surface wetness and non-dryness when it is wetted by liquid, so as to improve comfort and improve products performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

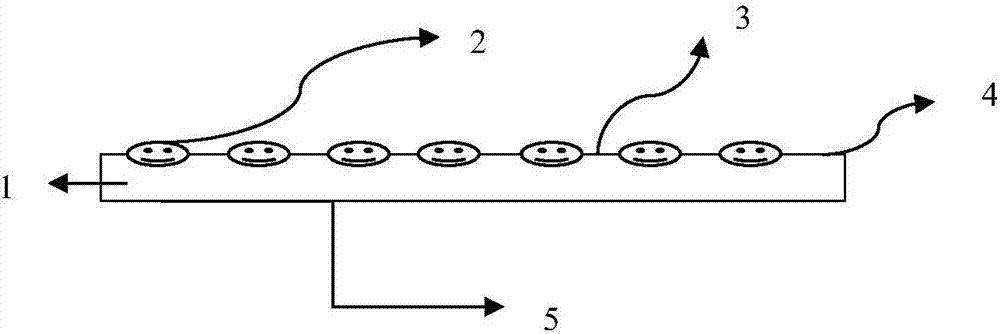

[0049] Embodiment 1: produce 30g / m 2 Cotton partially water-repellent spunlace fabric

[0050] Pure cotton fiber → carding → spunlace → local water repellent finishing → drying → coiling → inspection and cutting.

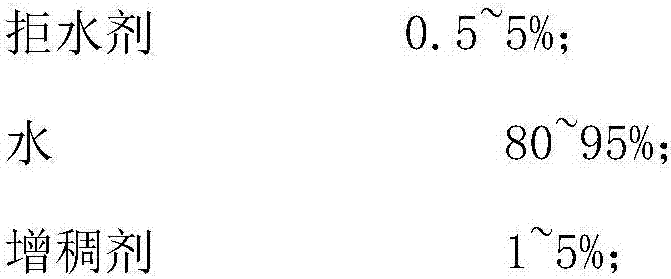

[0051] The water-repellent finishing liquid is made by mixing fluoride water-repellent agent, thickener and water.

[0052] The pure cotton spunlace cloth can be straight-laid spunlace cloth, cross-laid spunlace cloth, dry cloth, or wet cloth; this test is a cross-laid 35g pure cotton dry cloth.

[0053] The weight percentages added are

[0054]

[0055] Viscosity testing shows that the viscosity of the water-repellent finishing liquid of this embodiment is 2100mpa.s.

[0056] In the batching tank, according to the order of water→fluoride→thickener→ammonia water, add in order while stirring, and adjust to the appropriate viscosity. After the water-repellent finishing solution is prepared, it is put into the roller coating solution tank, and the water-repellen...

Embodiment 2

[0082] Embodiment 2: produce 15g / m 2 Partially water-repellent SS spunbond non-woven fabric is compared with ordinary hydrophilic SS.

[0083] SS spunbonded non-woven fabric unwinding → local water repellent finishing → drying → coiling → inspection and cutting.

[0084] The water-repellent finishing liquid is made by mixing fluoride water-repellent agent, thickener, hydrophilic agent and water.

[0085] The weight percentages added are

[0086]

[0087] Viscosity testing shows that the viscosity of the water-repellent finishing liquid of this embodiment is 2800mpa.s.

[0088] In the batching tank, follow the order of water → fluoride → antistatic agent → penetrant → thickener → ammonia water (the order of adding fluoride, antistatic agent, and penetrant is not affected), add them in sequence while stirring, and adjust to the appropriate viscosity. After the water-repellent finishing liquid is prepared, it is put into the roller coating liquid tank, and the water-repell...

Embodiment 3

[0103] Embodiment 3: produce 30g / m 2 Cotton partially water-repellent spunlace fabric

[0104] Pure cotton fiber → carding → spunlace → local water repellent finishing → drying → coiling → inspection and cutting.

[0105] The water-repellent finishing liquid is made by mixing fluoride water-repellent agent, thickener and water.

[0106] Pure cotton spunlace cloth can be straight-laid spunlace cloth, crossed spunlace cloth, dry cloth, or wet cloth; this test uses 35g straight-laid pure cotton spunlace cloth wet cloth.

[0107] The weight percentages added are

[0108]

[0109] Viscosity testing shows that the viscosity of the water-repellent finishing solution of this embodiment is 2600mpa.s.

[0110] In the batching tank, according to the order of water→fluoride→thickener→ammonia water, add in order while stirring, and adjust to the appropriate viscosity. After the water-repellent finishing solution is prepared, it is put into the roller coating solution tank, and the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com