Acid soil conditioner, preparation method and soil improvement method

An acid soil and conditioner technology, applied in soil conditioning materials, land preparation methods, chemical instruments and methods, etc., can solve the problems of pollution transfer, long repair time, and inability to solve multiple problems at the same time, so as to promote growth and reduce demand. , report the effect of water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

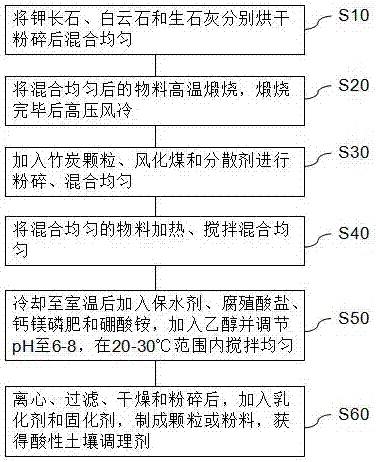

[0044] Such as figure 1 Shown, according to the preparation method of the acidic soil conditioner of the second aspect embodiment of the present invention, comprises the following steps:

[0045] Step S10, drying and pulverizing the potassium feldspar, dolomite and quicklime respectively, and mixing them uniformly;

[0046] Step S20, calcining the homogeneously mixed material at high temperature, and cooling with high-pressure air after the calcination;

[0047] Step S30, adding bamboo charcoal particles, weathered coal and dispersant to pulverize and mix evenly;

[0048] Step S40, heating and stirring the uniformly mixed material;

[0049] Step S50, after cooling to room temperature, add water retaining agent, humate, calcium magnesium phosphate fertilizer and ammonium borate, add ethanol and adjust the pH to 6-8, and stir evenly within the range of 20-30°C;

[0050] Step S60, after centrifuging, filtering, drying and pulverizing, adding emulsifier and solidifying agent to...

Embodiment 1

[0065] First, 20 parts of potassium feldspar, 10 parts of dolomite and 5 parts of quicklime were dried and pulverized, and mixed uniformly. After the uniformly mixed materials were passed through a 40-mesh sieve, they were calcined at 950°C at a high temperature. cold.

[0066] Then, take out the mixed material, add 5 parts of bamboo charcoal particles, 5 parts of weathered coal and 2 parts of dispersant, and further pulverize to improve the mixing uniformity.

[0067] Next, the homogeneously mixed material was stirred while being heated at 70°C.

[0068] Secondly, after cooling the material to room temperature, add 3 parts of water-retaining agent, 5 parts of humate, 1 part of calcium magnesium phosphate fertilizer and 1 part of ammonium borate, add ethanol and adjust the pH to 6-8, and mechanically Stir well.

[0069] Finally, after centrifugation, filtration, drying and crushing, 5 parts of emulsifier and 3 parts of curing agent are added to make granules or powder to obt...

Embodiment 2

[0071] First, 30 parts of potassium feldspar, 15 parts of dolomite, and 20 parts of quicklime were dried and pulverized, and then mixed uniformly. After the uniformly mixed materials were passed through a 40-mesh sieve, they were calcined at 950°C at a high temperature. cold.

[0072] Next, take out the mixed material and add 10 parts of bamboo charcoal particles, 10 parts of weathered coal and 5 parts of dispersant, and further pulverize to improve the mixing uniformity.

[0073] Next, the homogeneously mixed material was stirred while being heated at 70°C.

[0074] Secondly, after cooling the material to room temperature, add 5 parts of water-retaining agent, 10 parts of humate, 2 parts of calcium magnesium phosphate fertilizer and 2 parts of ammonium borate, add ethanol and adjust the pH to 6-8, and mechanically Stir well.

[0075] Finally, after centrifugation, filtration, drying and pulverization, 10 parts of emulsifier and 5 parts of curing agent are added to make gran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com