Three-dimensional continuous printing platform device

A technology of printing platform and printing plate, applied in processing platform/substrate, additive processing, etc., can solve problems such as low efficiency and achieve the effect of continuous printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

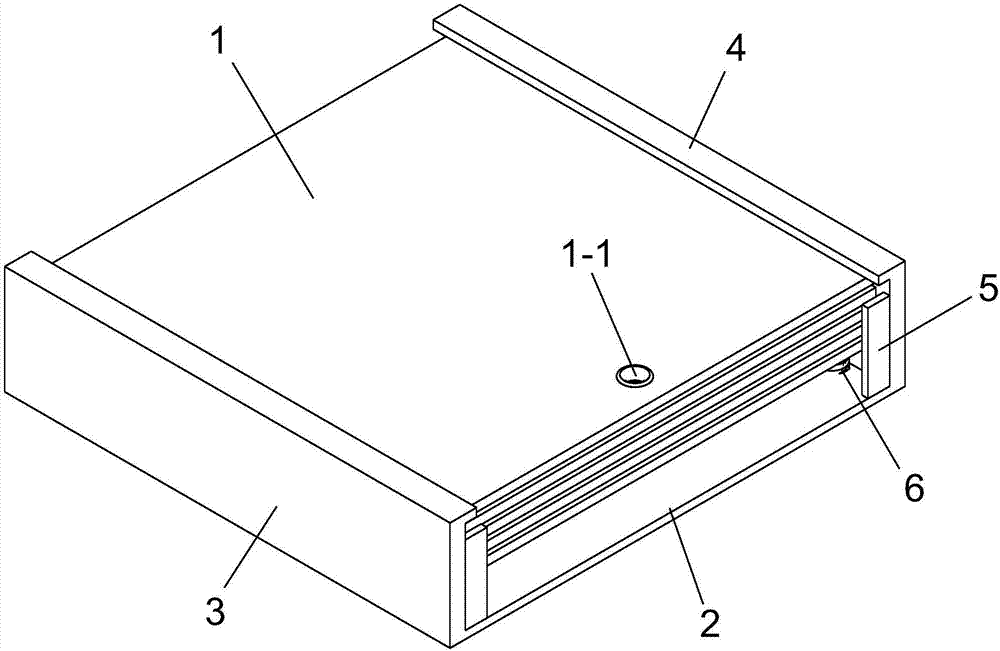

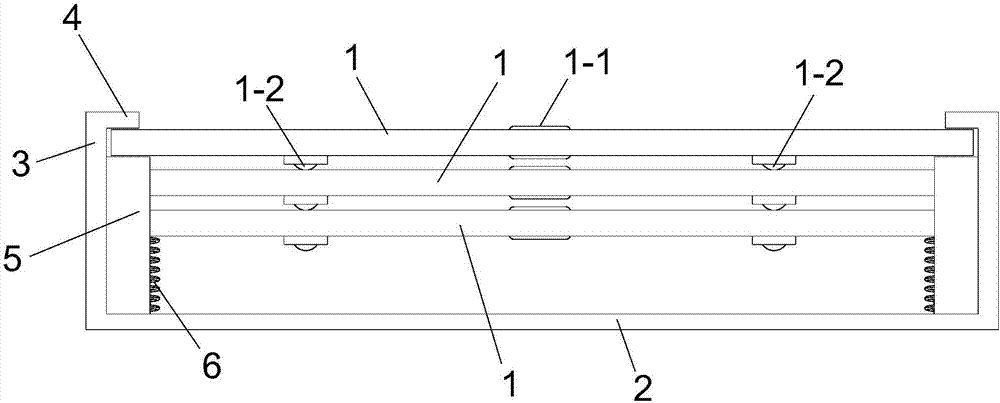

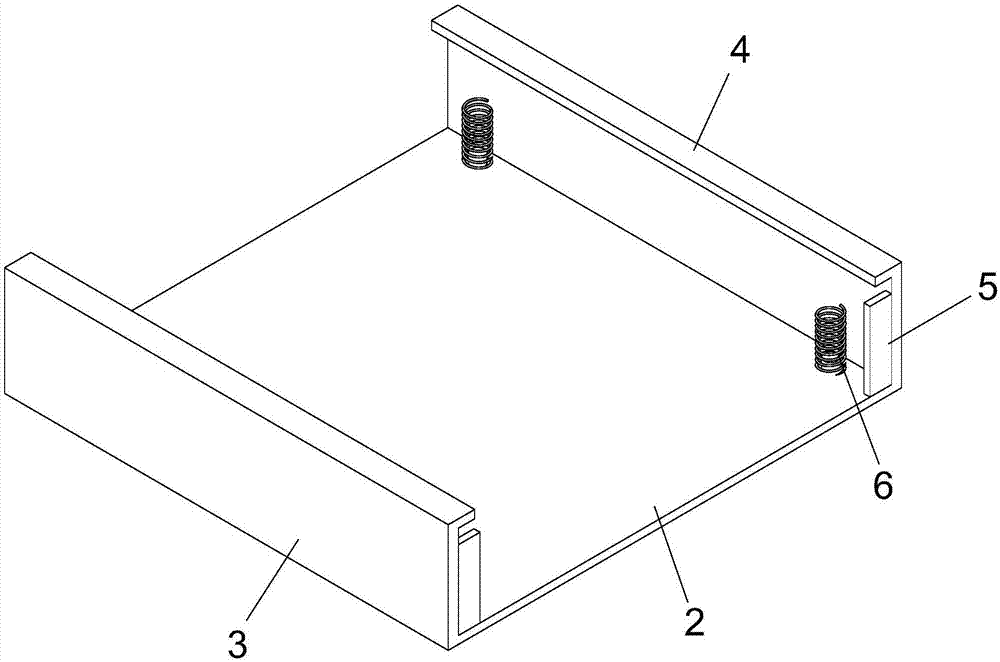

[0030] Such as Figure 1-4 As shown, the bottom surface of the printing plate 1 is provided with a sliding member 1-2 that slides and rubs against the upper side of the printing plate 1 on the lower layer.

[0031] Preferably, the sliding member 1-2 can be a ball.

[0032] There are four sliders 1-2 in total, which are respectively arranged on the peripheral side of the printing plate 1.

[0033] A baffle 5 is provided on the front and / or rear of the fixing bracket, and the baffle 5 blocks the front or rear of the printing plate 1 below the uppermost layer.

[0034] The arrangement of the sliders 1-2 can reduce the horizontal friction force between the upper and lower printing plates 1 .

[0035] The setting of the baffle plate 5 limits the displacement in the horizontal direction of the printing plate 1 below the second layer, so that it can only complete the vertical displacement.

Embodiment 2

[0037] Such as Figure 5-10 As shown, a number of barriers 7 are also provided between the printing plates 1, and the inner wall of the side plate 3 is provided with a vertically extending limiting track 3-1;

[0038] The barrier member 7 is slidably arranged in the limit track 3-1, and the barrier member 7 extends into the fixed bracket, and the upper and lower parts of the segment of the barrier member 7 extend into contact with the printing plate 1;

[0039] The limit plate 4 is provided with a through hole 4-1 through which the spacer 7 passes through corresponding to the position of the limit track 3-1.

[0040] The inner wall of the side plate 3 is provided with at least two limit rails 3-1, and each limit rail 3-1 is spaced in front and back.

[0041] The barrier 7 is T-shaped, and the limiting track 3-1 is a T-shaped track.

[0042] The upper and lower surfaces of the barrier member 7 are smooth surfaces.

[0043] A barrier member 7 is provided between the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com