Welding anti-deformation water-cooling device for drive tube base penetrating part and using method of welding anti-deformation water-cooling device

A water-cooling device and anti-deformation technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as affecting the welding operation of welding operators, preventing welding deformation of the sealing welding of the driving tube seat, and damage to the inner wall of the driving tube seat, etc. The effect of low labor intensity and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

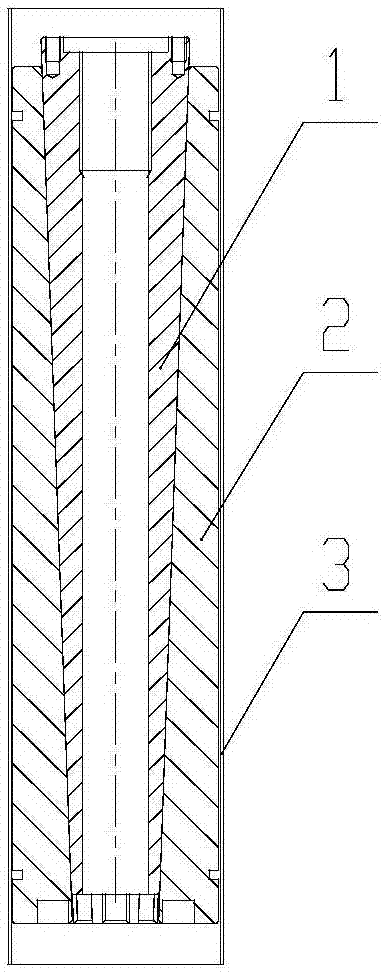

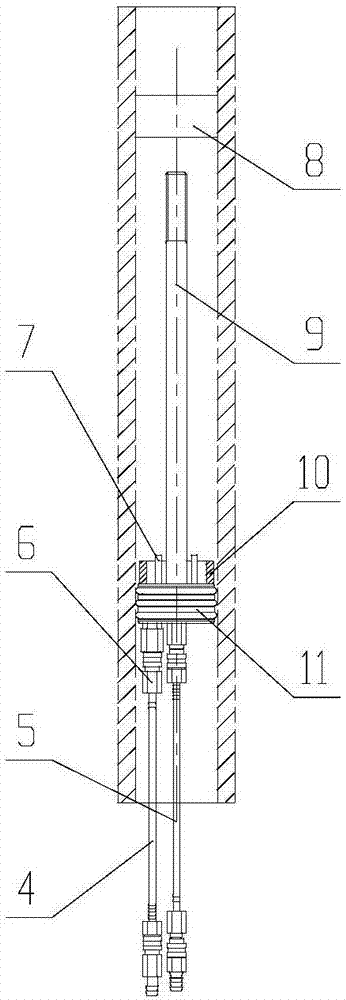

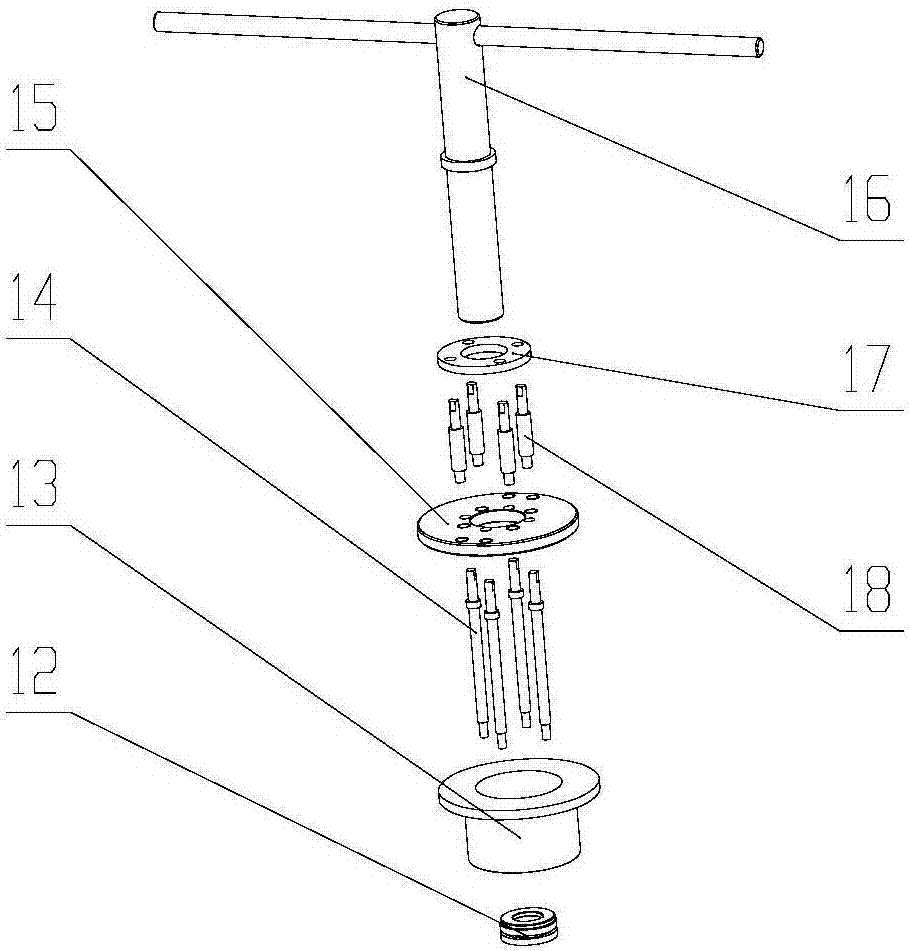

[0043] Such as Figure 1 to Figure 7 As shown in the figure, an anti-deformation water-cooling device for welding the penetrating part of the drive pipe seat includes: a rigid restraint mechanism, a water-cooling mechanism and a circulating cooling water tank; the water-cooling mechanism includes: a water inlet hose 4, a return water hose 5, and a quick connector 6 , the lower sealing plug 11, the sector limit ring 10, the stop pin 7, the return pipe 9 and the upper sealing plug 8; the upper sealing plug 8 and the lower sealing plug 11 are respectively arranged on the upper and lower sides of the drive tube seat end, the axis of the lower sealing plug 11 is provided with a through hole, the upper end of the through hole of the lower sealing plug 11 is provided with a return pipe 9, and the lower end is provided with a return hose 5; the upper end of the lower sealing plug 11 The surface is provided with a non-rotation pin 7 and a sector stop ring 10, and the lower end of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com