Gear chamfering device

A technology of chamfering device and gear, applied in the direction of gear tooth manufacturing device, belt/chain/gear, gear tooth, etc., can solve the problems of pollution, dust can not be effectively collected, easy to spread and hurt people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

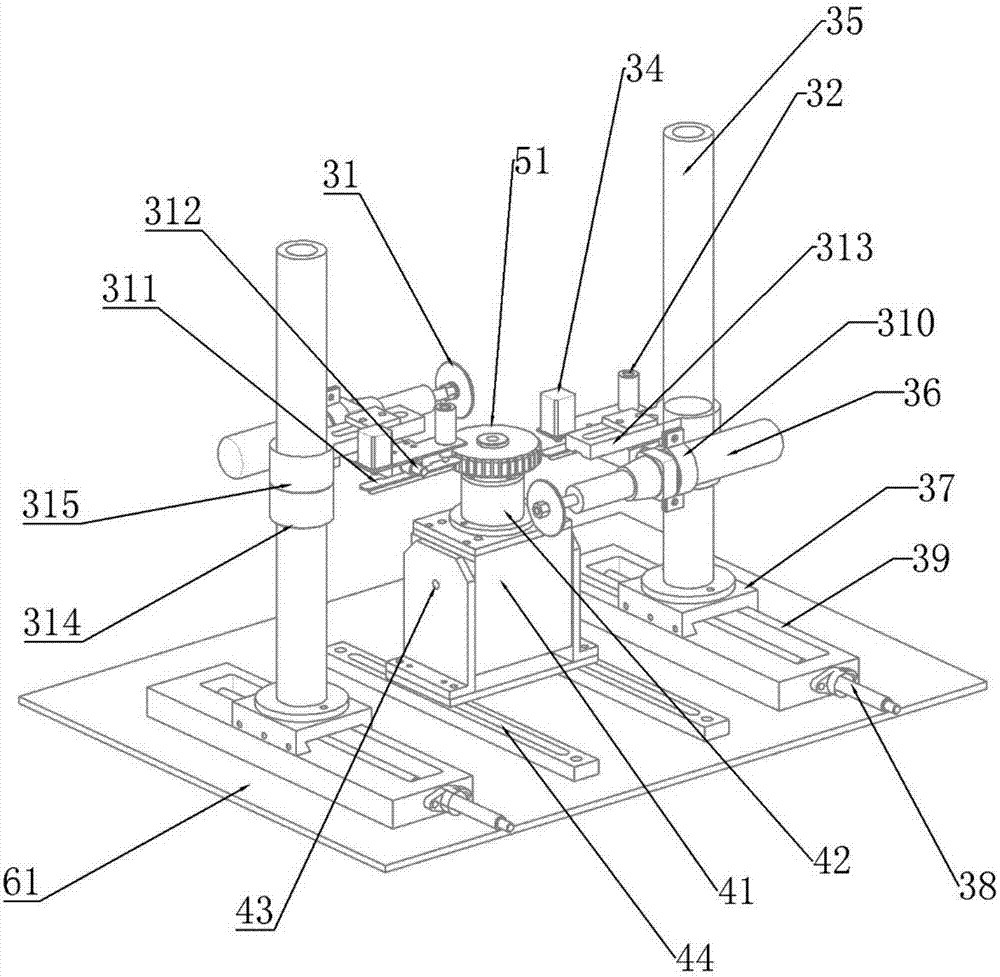

[0016] The reference numerals in the accompanying drawings of the description include: vacuum bin 11, housing 21, door 22, transparent observation window 23, grinding wheel sheet 31, spring 32, hand wheel 33, cylinder 34, threaded column 35, electric grinder 36, Slider 37, screw mandrel 38, slide rail 39, clamp 310, balance plate 311, rotating shaft 312, fixed plate 313, threaded part 314, rotating arm 315, main chassis 41, tooling 42, pin shaft 43, T-shaped slot 44 , gear 51, connecting plate 61.

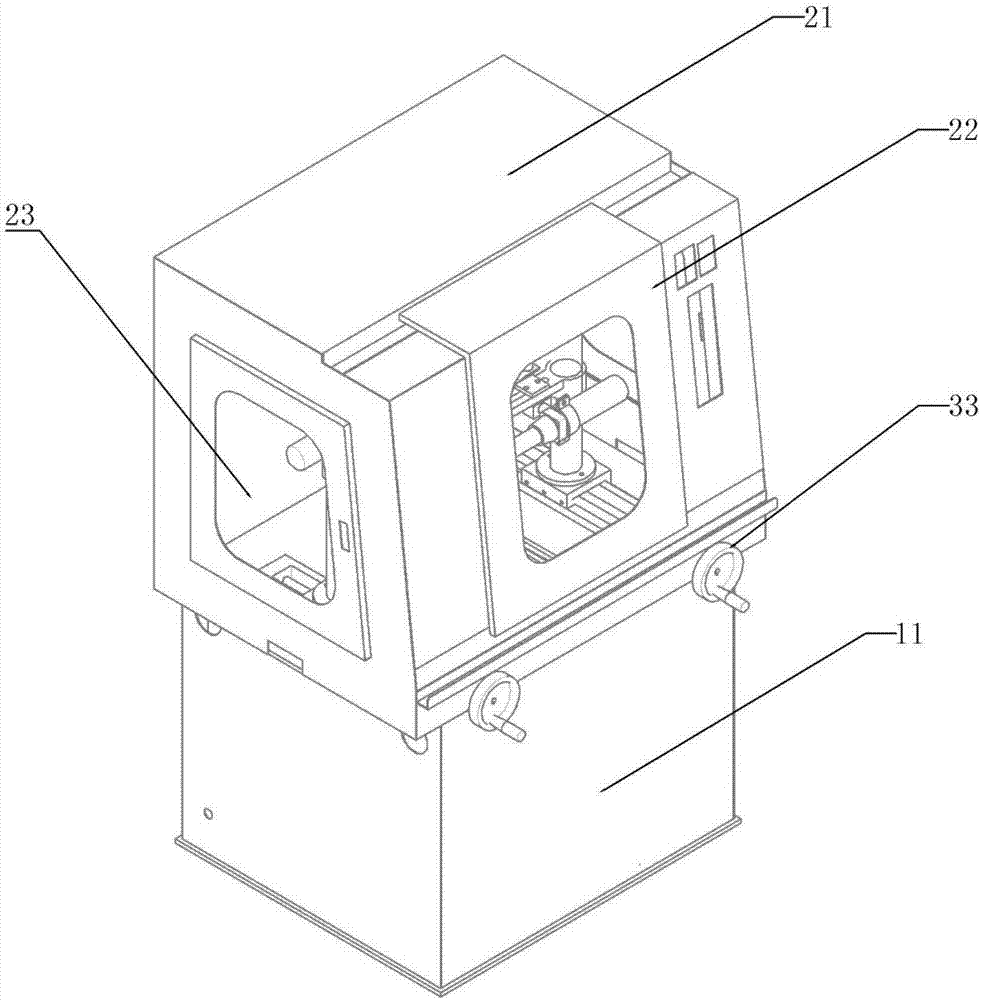

[0017] The embodiment is basically as attached figure 1 and figure 2 Shown: a gear chamfering device, including a housing 21, a chamfering structure and a dust removal structure, the side wall of the housing 21 is provided with a door 22, and the side of the housing 21 is provided with a transparent observation window 23, which can pass through the transparent observation w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com