Part turnover mechanism for automatic lathe production line

A technology of automatic car and turning mechanism, which is applied in the direction of metal processing, etc., can solve the problems that are not conducive to the fully automatic operation of industrial production, affect the production efficiency of the workpiece yield rate, and are prone to work-related accidents, so as to realize fully automatic operation and improve the overall production The effect of efficiency, good support and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

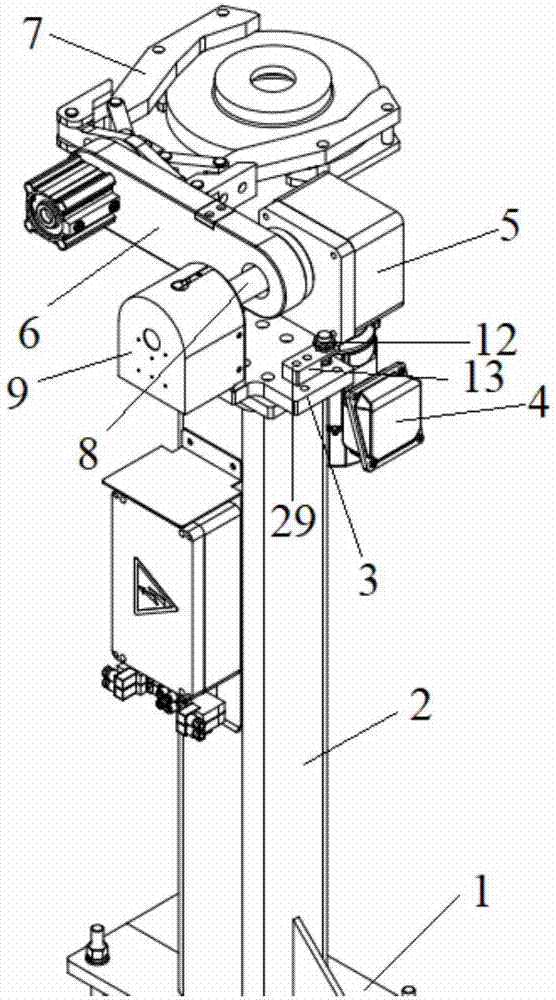

[0022] Embodiment 1: A parts turnover mechanism for an automated lathe production line, including a base 1, a column 2, a mounting plate 3, a motor 4, a reducer 5, a rocker arm 6 and a jaw mechanism 7, the lower surface of the column 2 fixed on the upper surface of the base 1, the mounting plate 3 is installed on the upper surface of the column 2, the motor 4 and the reducer 5 are fixedly installed on the front surface of the column 2, the output shaft of the motor 4 is connected to the reducer 5, The reducer 5 is connected to the rocker arm 6 through a connecting rod 8 to drive the rocker arm 6 to swing, and the jaw mechanism 7 is installed on the end of the rocker arm 6 away from the connecting rod 8;

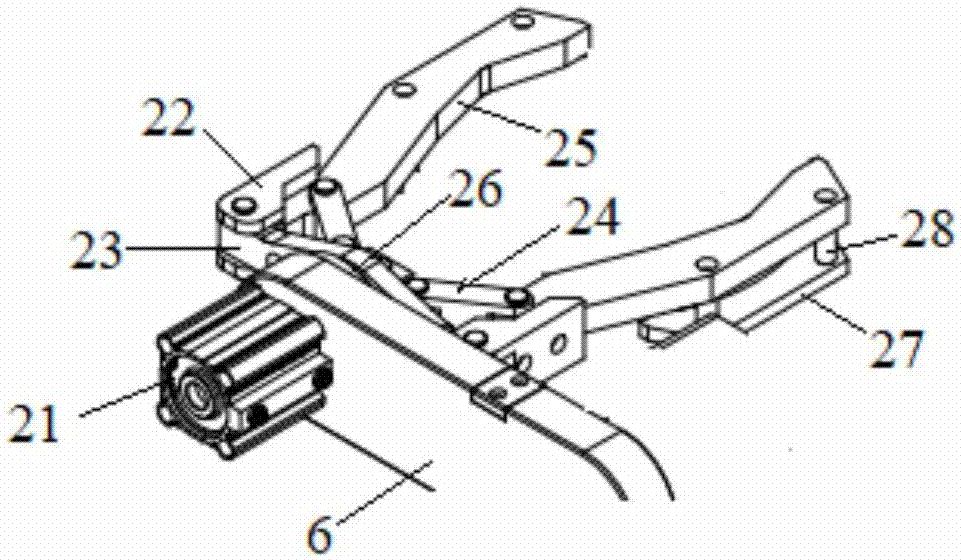

[0023] The jaw mechanism 7 further includes a cylinder 21, a claw joint 22, a connecting seat 23, a hinge seat 24, a claw 25 and a telescopic rod 26, and the cylinder 21 is installed on the rear side surface of the rocking arm 6, and the piston rod of the cylinder 21 Pass thr...

Embodiment 2

[0027] Embodiment 2: A parts turnover mechanism for an automated lathe production line, including a base 1, a column 2, a mounting plate 3, a motor 4, a reducer 5, a rocker arm 6 and a jaw mechanism 7, and the lower surface of the column 2 is fixed on the upper surface of the base 1, the mounting plate 3 is installed on the upper surface of the column 2, the motor 4 and the reducer 5 are fixedly installed on the front surface of the column 2, the output shaft of the motor 4 is connected to the reducer 5, The reducer 5 is connected to the rocker arm 6 through a connecting rod 8 to drive the rocker arm 6 to swing, and the jaw mechanism 7 is installed on the end of the rocker arm 6 away from the connecting rod 8;

[0028] The jaw mechanism 7 further includes a cylinder 21, a claw joint 22, a connecting seat 23, a hinge seat 24, a claw 25 and a telescopic rod 26, and the cylinder 21 is installed on the rear side surface of the rocking arm 6, and the piston rod of the cylinder 21 P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com