An intelligent automatic bucket washing equipment

A fully automatic and intelligent technology, applied in cleaning methods and utensils, chemical instruments and methods, household utensils, etc., can solve the problems of omissions, hidden dangers, secondary pollution, etc. Wide range of properties and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

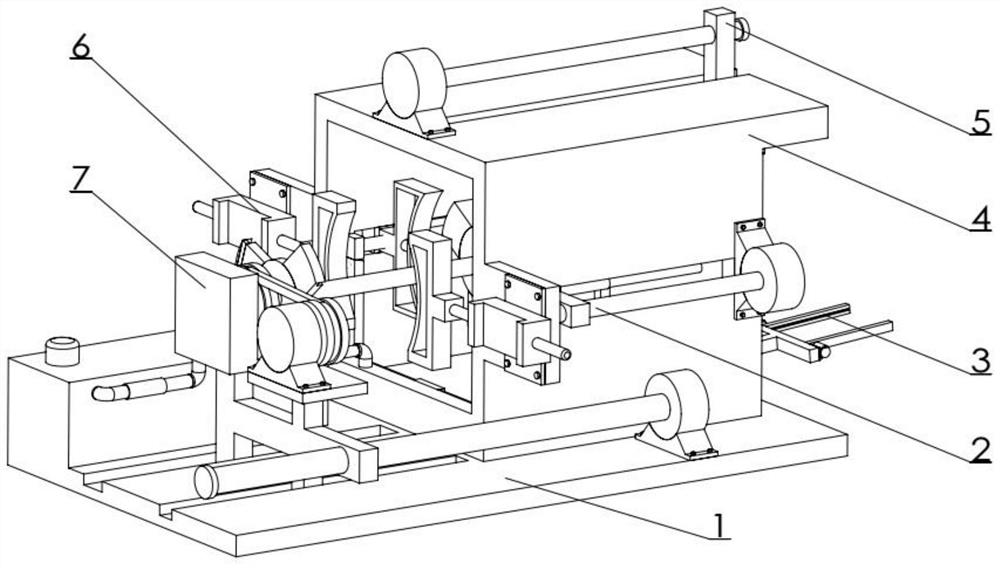

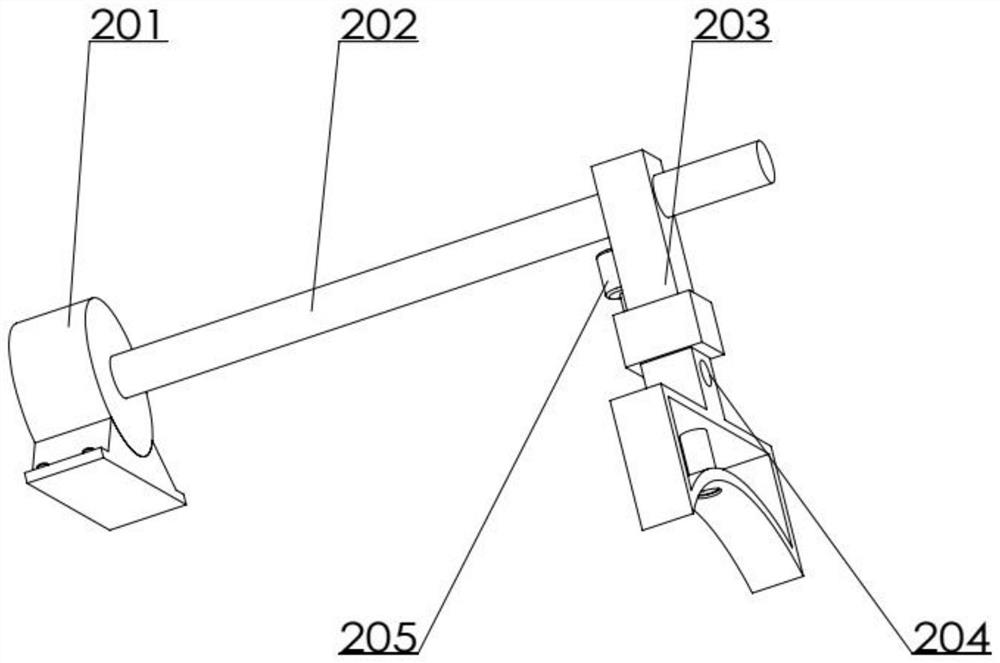

[0023] An intelligent full-automatic bucket washing equipment is composed of a base 1, an external cleaning machine 2, a first grasping device 3, a bucket washing box 4, a second grasping device 5, a front clamping device 6 and an internal cleaning machine Composed of 7, the first grabbing device 3 is fixedly installed on the edge of the base 1, the second grabbing device 5 is installed on the upper part of the barrel washing box 4, and the two front clamping devices 6 are symmetrical and fixedly installed on the barrel washing box 4 At the front, two external cleaning machines 2 are installed symmetrically on the left and right sides of the bucket washing box 4, and the bucket washing box 4 is fixedly installed on one side of the base 1 as a whole, and the internal cleaning machine 7 is installed on the other side of the base 1.

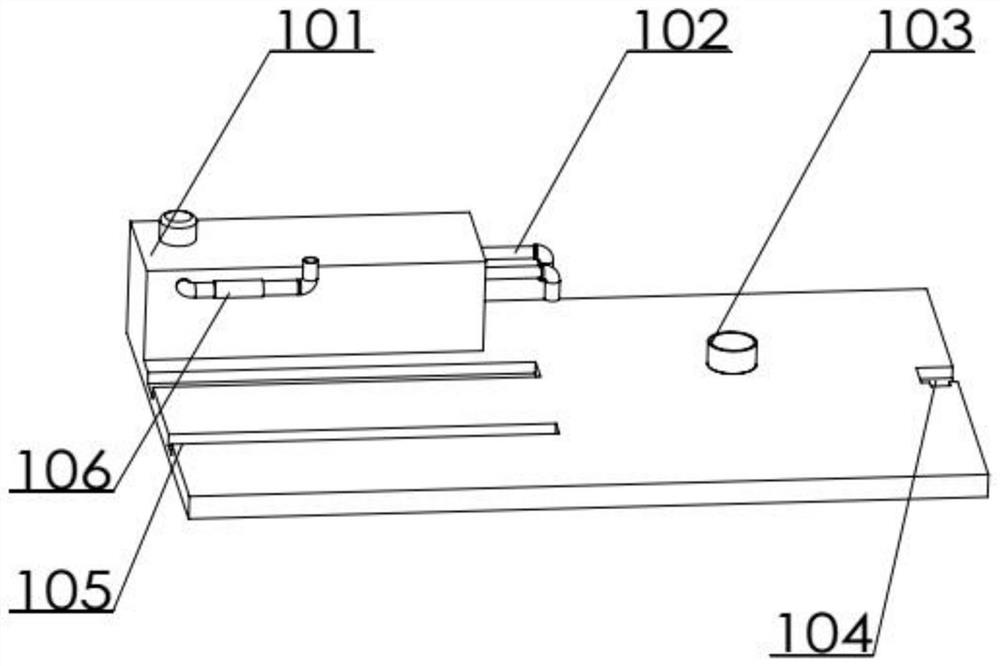

[0024] The base 1 is composed of a water tank 101, a water tank outlet pipe 102, a base drain pipe 103, a gripping device groove 104, a bracket trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com