Underwater umbilical cable terminal dragging system

An umbilical cable terminal and watertight technology, applied in the direction of electrical components, base/housing, coupling devices, etc., can solve the problems of limited drag carrying capacity, weakened reliability, simple structure, etc., and achieve improved equipment reliability, high technical level, Easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

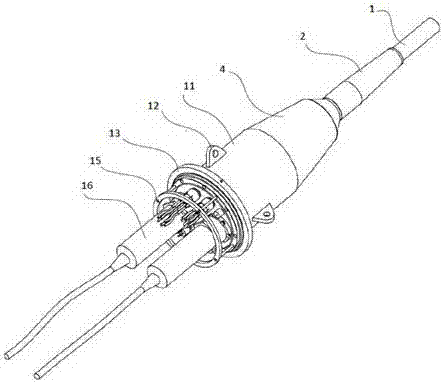

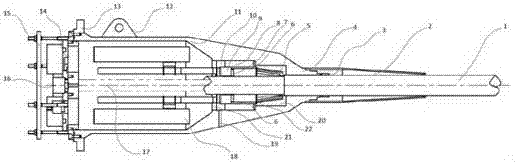

[0033] Examples, such as Figure 1-3 As shown, an underwater umbilical cable terminal towing system includes a sealed shell 4, and the sealed shell 4 has a truncated cone shape.

[0034] The sealing shell 4 has a big head end and a small head end. The small head end of the sealing shell 4 is threadedly connected with a compression nut 3, and the compression nut 3 is connected with the sealing shell 4 to compress the outer sheath of the cable.

[0035] A cylindrical pressure cabin 11 is fixedly connected to the big end of the sealed shell 4.

[0036] The sealed shell 4 has a first cavity 20 and a second cavity 21. The first cavity 20 and the second cavity 21 are in communication with each other. The first cavity 20 and the second cavity 21 are both cylindrical cavities. A cavity 20 and the second cavity 21 are arranged coaxially, a step 22 is formed between the first cavity 20 and the second cavity 21, and the first cavity 20 is arranged at a position close to the small end of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com