Sparse feature extraction method for fault signal of rotating machine

A technology for rotating machinery and fault signals. It is used in the identification of patterns in signals, computer parts, instruments, etc., and can solve problems such as non-adaptability, difficulty, and time-frequency resolution of time-frequency spectrum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

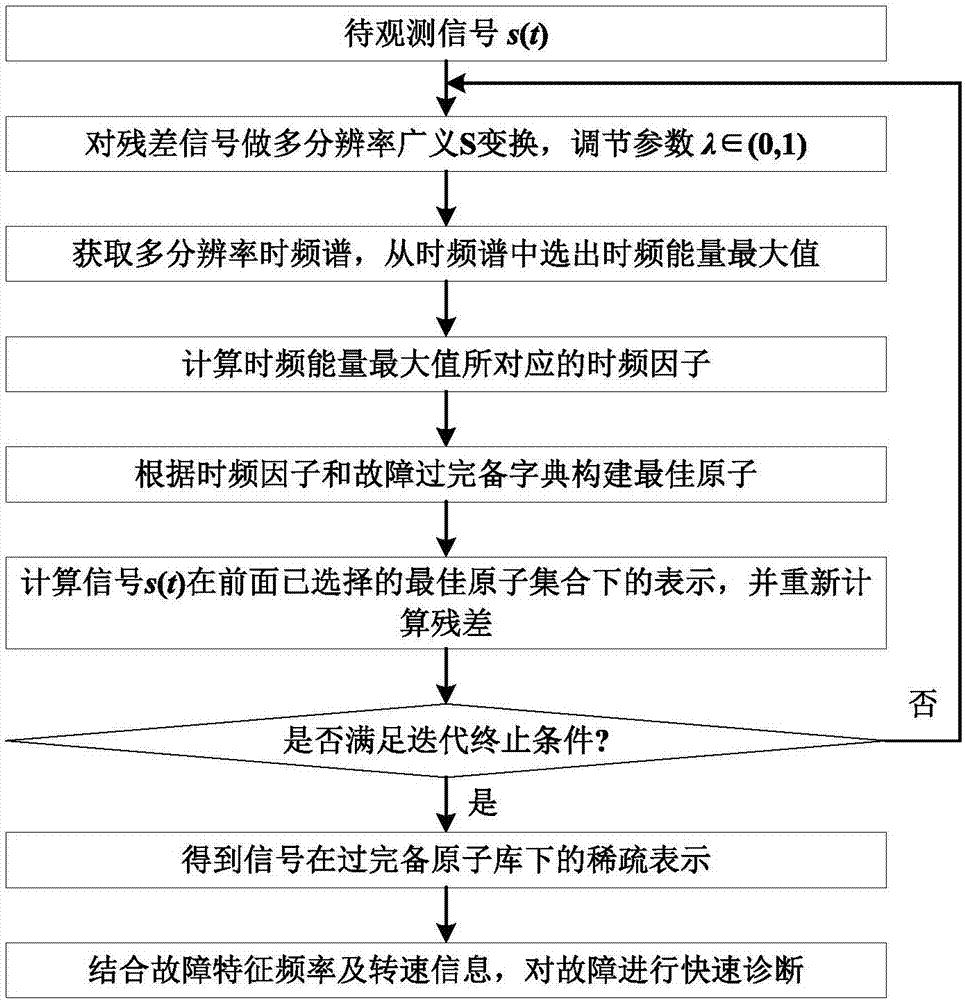

[0073] A sparse feature extraction method for rotating machinery fault signals, comprising the following steps:

[0074] Step A. According to the fault generation mechanism of the rotating machinery impact fault, construct a fault over-complete atomic library.

[0075] Combined with the mechanism of impact faults and the characteristics of damped vibration, the fault overcomplete atomic library Φ is constructed according to the following atomic expressions of the overcomplete atomic library.

[0076] The atoms g(t) in the over-complete atomic library Φ are as follows:

[0077]

[0078] in,

[0079] g(t)——the atoms of the complete atomic library;

[0080] u—displacement factor;

[0081] f - frequency factor;

[0082] λ—scale factor;

[0083] - phase factor;

[0084] t - time.

[0085] It is called the time-frequency fact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com