Plasma height adjusting apparatus and method

A plasma and height adjustment technology, applied in material excitation analysis, thermal excitation analysis, etc., can solve the problems of complex mechanical design, hidden dangers of microwave radiation, wear, etc., to avoid mechanical loss, simple and compact structure, and improve the effect of safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

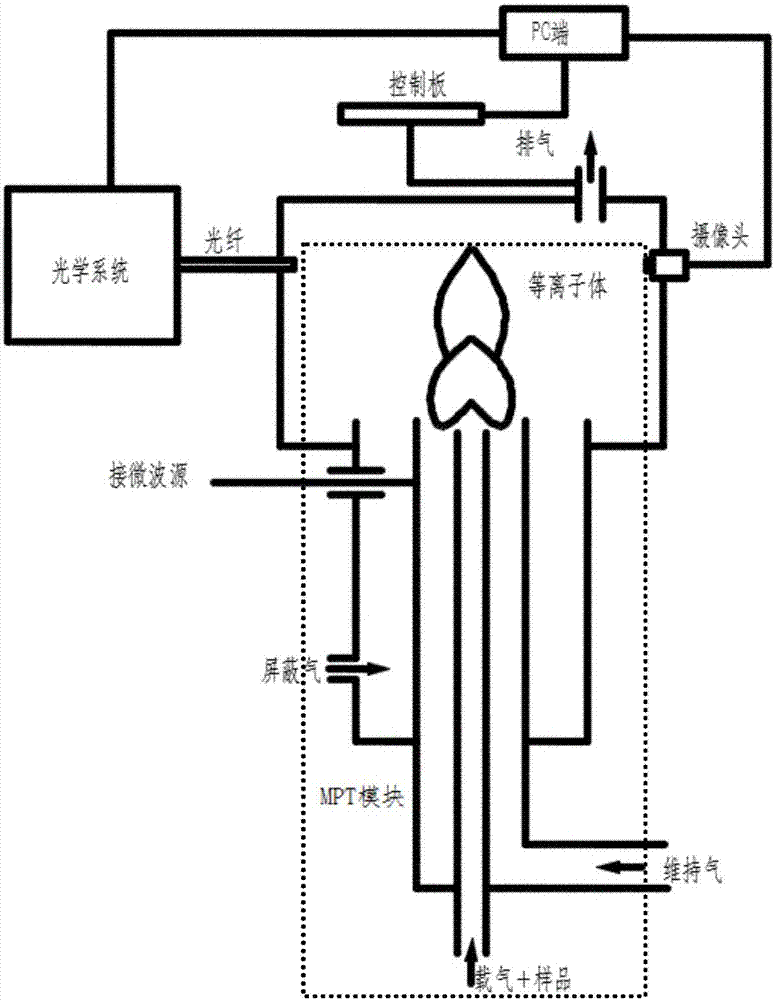

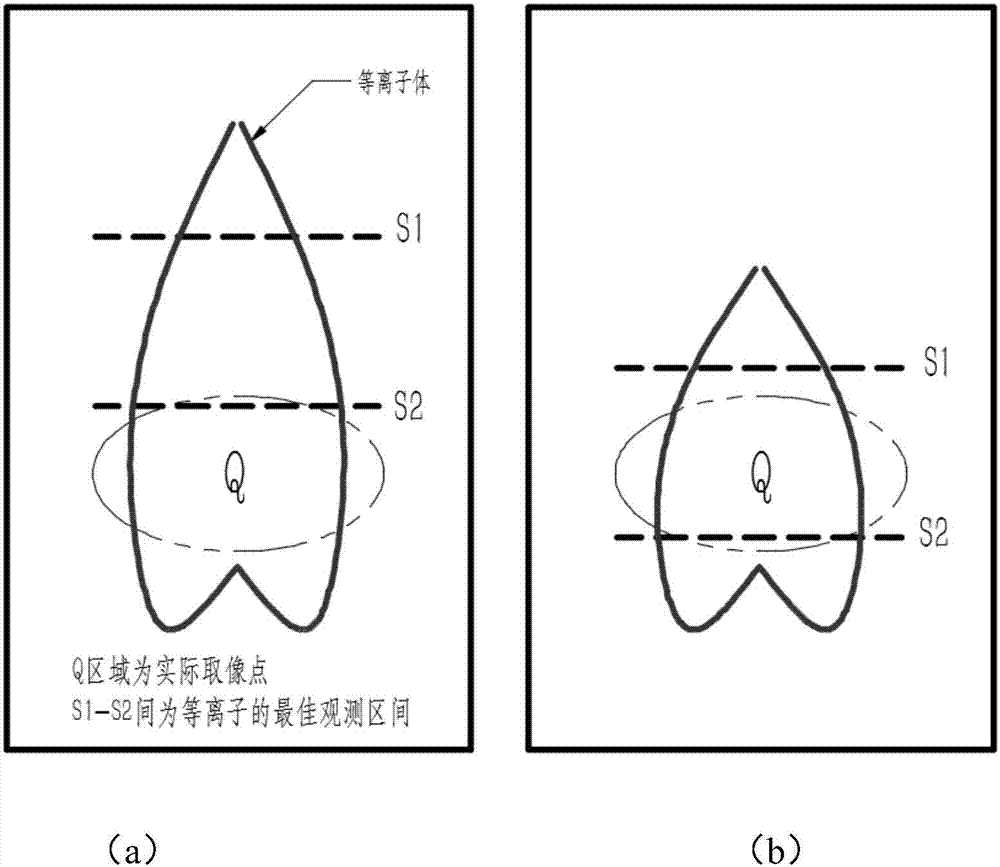

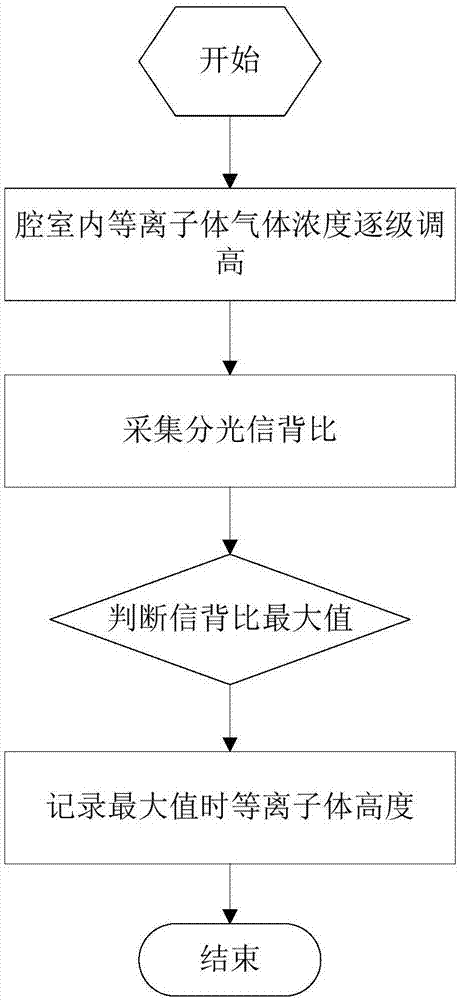

[0043] Such as figure 1 Shown, a kind of plasma height adjusting device comprises MPT module (dotted frame part), optical fiber probe, optical system, camera, detection terminal, control board and exhaust module, and described MPT module is plasma torch; The exhaust module is used to exhaust the chamber of the plasma torch; the optical fiber probe is used to obtain the optical signal generated by the plasma; the optical system is connected to the optical fiber probe for The optical signal from the probe generates a spectrogram; the camera is used to take images of the plasma; the detection terminal is used to control the exhaust speed of the exhaust module through the control board, according to the output generated by the optical system The spectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com