Refractory kiln brick with blind-hole-structure connecting holes

A technology for structural connection and connection holes, applied in the field of refractory kiln bricks, can solve the problems of inconvenient and stable positioning and connection, insufficient connection strength of brick bodies, etc., so as to improve the efficiency of positioning connection, reduce the mutual separation of brick bodies, and reduce structural strength. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

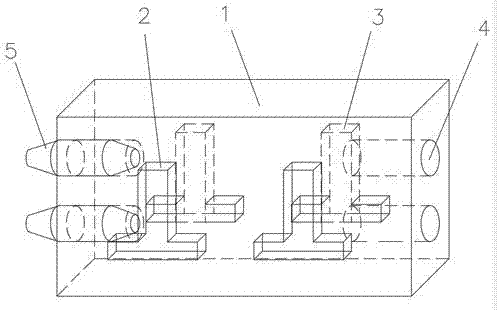

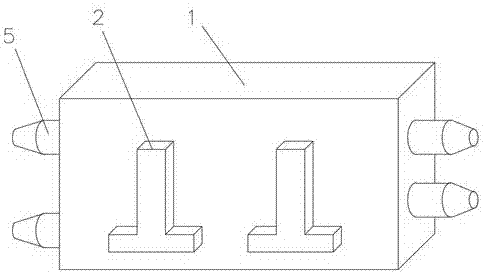

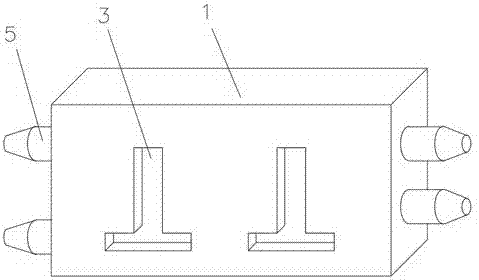

[0030] Example 1, such as Figure 1-5 Shown:

[0031] A refractory kiln brick with connecting holes in a blind hole structure, comprising a brick body 1 with a cuboid structure, the brick body 1 includes a front facing at the front of the brick body 1 and a rear facing at the rear of the brick body 1, the brick body There are two T-shaped protrusions 2 arranged side by side on the front face of the brick body 1; two T-shaped grooves 3 matching the protrusions 2 are arranged on the rear face of the brick body 1; There are several connecting holes 4 with blind hole structure symmetrically arranged on both sides, and the connecting shaft 5 is detachably installed in the connecting hole 4; the connecting shaft 5 includes a middle section 6 in the middle and a tapered End 7.

[0032] On the one hand, the present invention matches and embeds the protrusions 2 and the grooves 3 of the T-shaped structure, so that the front and rear bricks 1 can be positioned and installed, and at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com