Jet Nozzles for Gentle Combustion Chambers of Gas Turbines

A technology of jet nozzles and gas turbines, which is applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of unfavorable establishment and realization of soft combustion, reduction of flue gas return ratio, and large pressure loss, and achieve ultra-low nitrogen oxidation The effect of reducing the emission of pollutants, reducing the peak flame temperature, and reducing the pressure loss

Active Publication Date: 2019-10-01

INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In general, in order to ensure uniform mixing of fuel and air, the nozzle adopts a strong swirl design. On the one hand, such a design often causes a large pressure loss, and the reaction zone is close to the outlet of the nozzle, which may easily cause local overheating of the nozzle. On the other hand, , the strong swirling jet of the nozzle will weaken the recirculation zone and reduce the flue gas recirculation ratio, which is not conducive to the establishment and realization of soft combustion

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

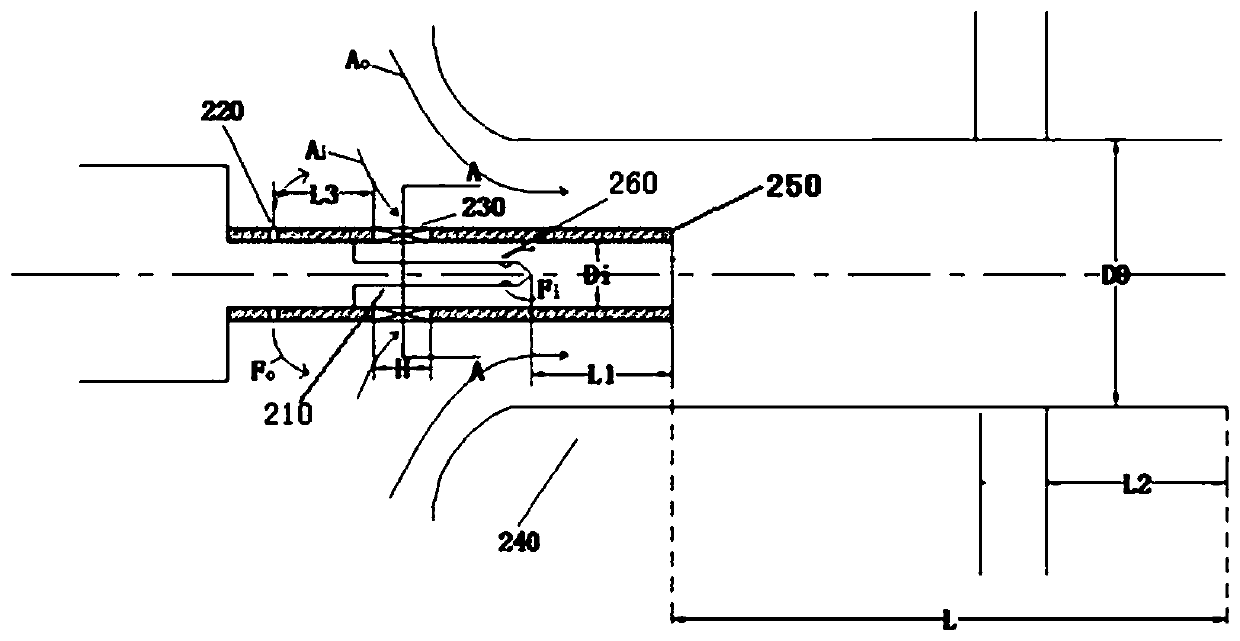

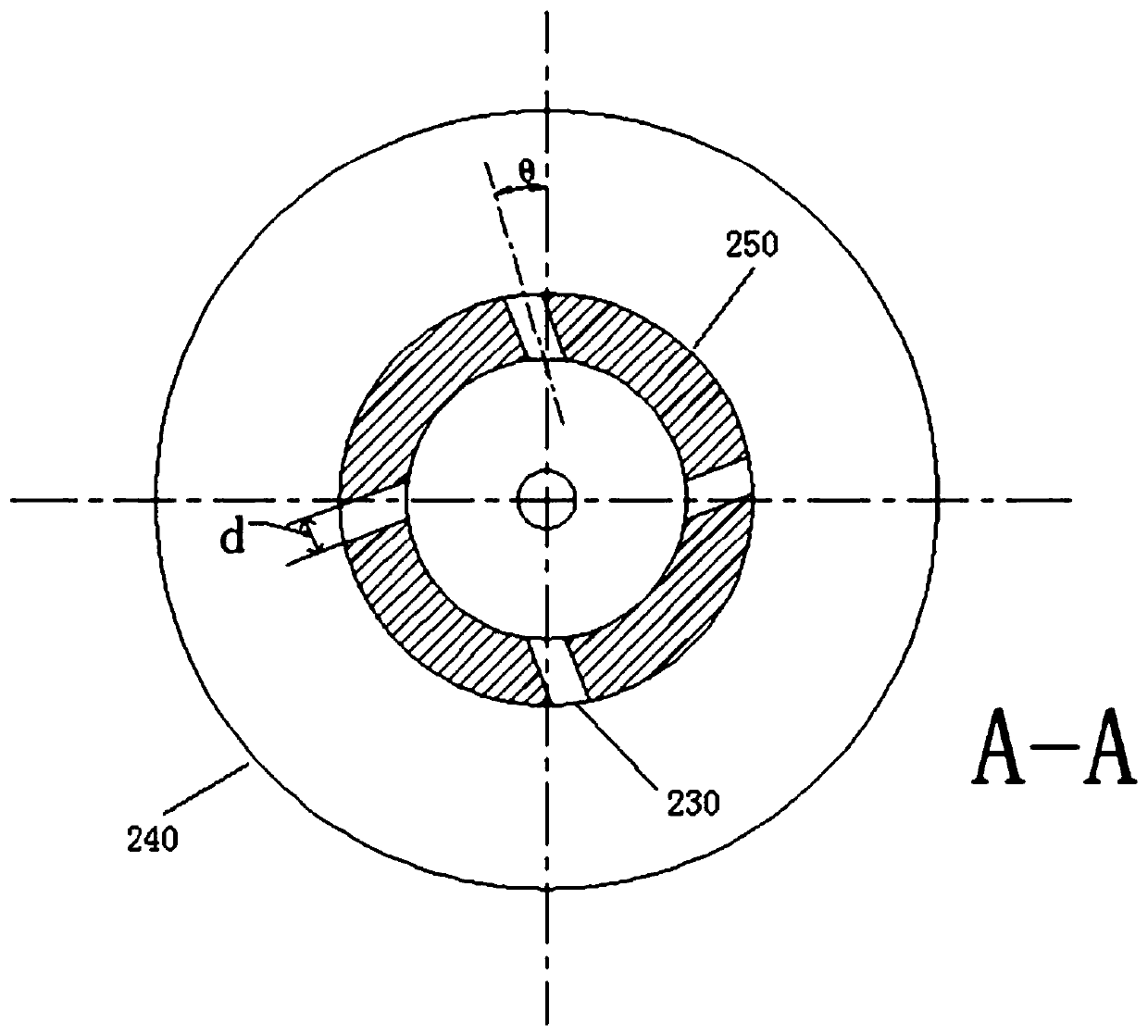

A jet nozzle of a mild combustion chamber of a gas turbine comprises a fuel inside nozzle, a fuel outside spray hole, multiple rotational flow groove channels, an outside pipeline and an inside pipeline. The mixing uniformity of fuel and air at a jet nozzle outlet is improved, the outside fuel-air equivalence ratio is relatively low, flame root lifting is facilitated, too-early ignition does not occur easily, jets of the jet nozzle belong to weak rotational flows, the overall pressure loss is relatively low, the axial speed is not prone to attenuation, and increase of the smoke reflux ratio ofthe combustion chamber is facilitated.

Description

technical field The invention relates to the technical field of gas turbines, in particular to a jet nozzle for a soft combustion chamber of a gas turbine. Background technique Nitrogen oxides include nitrous oxide, nitrogen monoxide, and nitrogen dioxide. Nitrogen oxides, as the main air pollutants, can cause poisonous damage to animals and plants, and are also one of the main causes of acid rain, acid fog and photochemical smog. Gas turbine is an important power equipment. On the one hand, it is necessary to continuously increase the outlet temperature of the combustion chamber to improve the efficiency of the gas turbine. On the other hand, it is necessary to further reduce the emission of nitrogen oxides in a wide range of operating conditions. Under the premise of maintaining combustion efficiency and performance, reducing the emission of nitrogen oxides has always been the key goal of gas turbine combustion researchers. For gas turbines whose combustor outlet temper...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F23R3/28F23R3/38

Inventor 熊燕刘耘州俞镔张哲巅肖云汉

Owner INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com