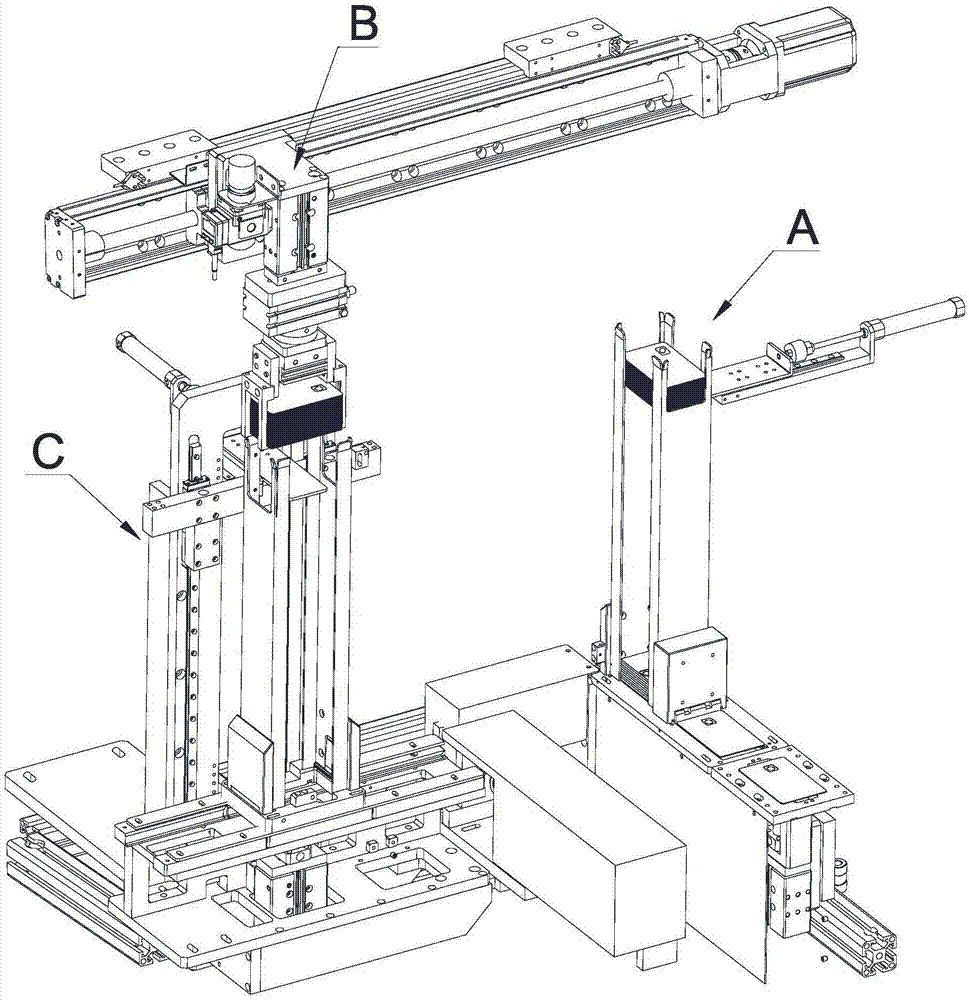

Smart card storing, taking and carrying device

A technology of handling device and smart card, which is applied in the directions of transportation and packaging, stacking receiving device, separation of objects, etc., can solve the problems of delaying the use of cards for production equipment, restricting production and processing efficiency, restricting handling efficiency, etc. Good effect and high handling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The vertical drive mechanism is connected with the slide block in the screw drive mechanism, and the rotation drive mechanism and the telescopic drive mechanism are sequentially connected below the vertical drive mechanism.

Embodiment 2

[0051] The rotary drive mechanism is connected with the slide block in the screw drive mechanism, and the vertical drive mechanism and the telescopic drive mechanism are sequentially connected under the rotary drive mechanism.

[0052] In the above-mentioned embodiment 1 and embodiment 2, although the installation positions of the rotary drive mechanism and the vertical drive mechanism are different, it does not affect the realization of the functions of each mechanism.

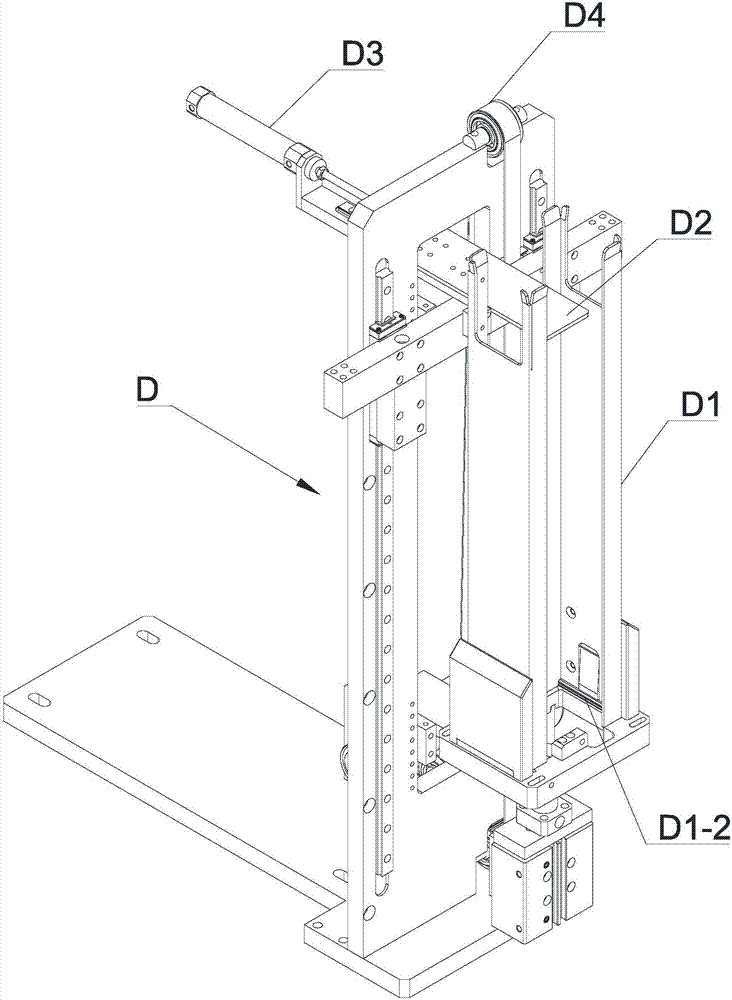

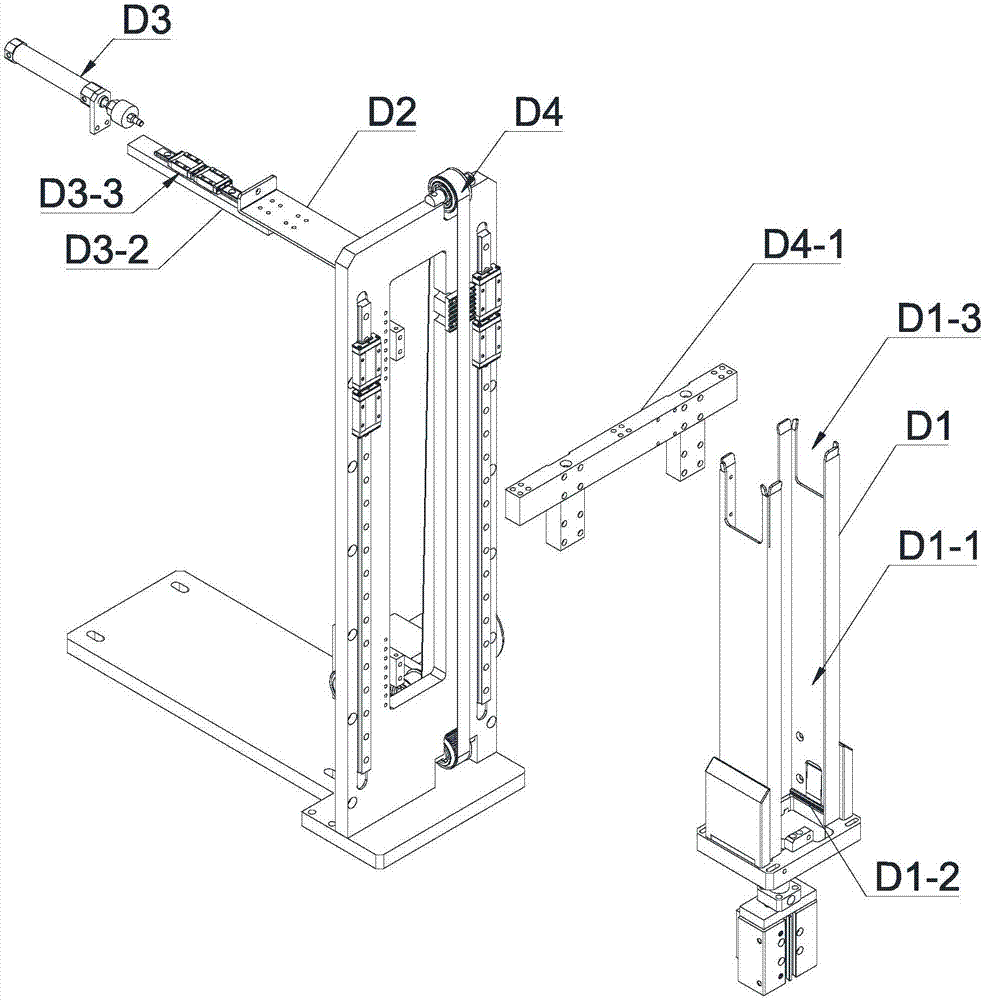

[0053] When working, the rotation of the screw rod drives the slider to rotate, and then drives the guide rod cylinder connected to the slider, the rotary cylinder, the slide cylinder, the claw C1 and the card set to go back and forth between the card taking mechanism A and the card storage mechanism B. horizontal movement. The advantage of this setting is that the screw drive mechanism has high motion precision and stable operation, and can accurately stay above the card bucket D1 in the card taking mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com