Finished paper winding device

A technology of winding device and paper, which is applied in the direction of stacking receiving device, transportation and packaging, sending objects, etc., and can solve the problems affecting the quality of film production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

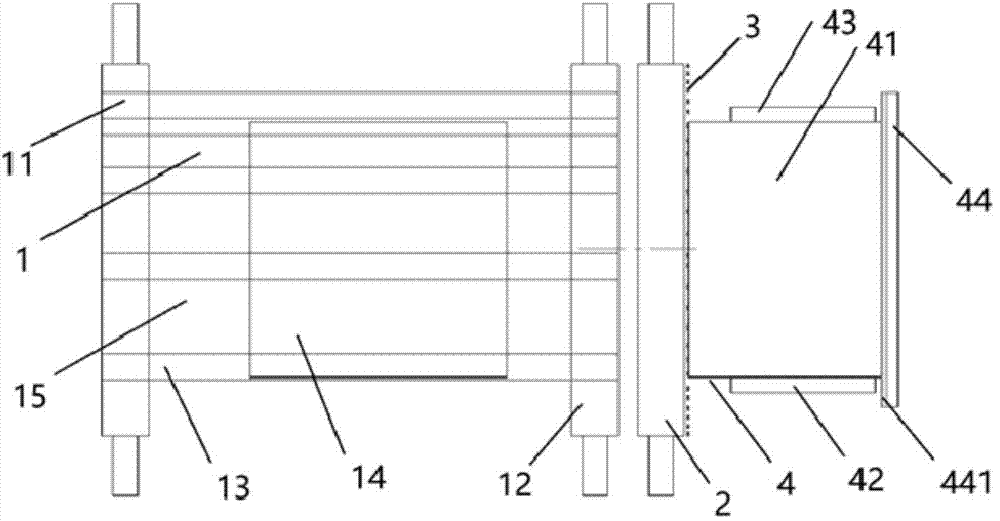

[0041] The present application provides a finished paper winding device, which includes a paper conveying assembly 1 , a first roller body 2 , a first baffle 3 and a paper collection platform 4 .

[0042] see figure 1 , is a structural schematic diagram of a finished paper winding device provided in this application.

[0043] The paper conveying assembly 1 is a conveying platform. After coating, molding, cutting, aluminizing, paper film compounding, drying and other processes, the finished paper is passed through the paper conveying assembly 1 to complete the final winding, so as to complete Paper final stage delivery work. There is a toothed guide rail under the paper conveying assembly 1, and the guide rail is driven by a motor, and then drives the paper conveying assembly 1 to move.

[0044] The paper conveying assembly 1 is connected to one end of the first roller body 2 .

[0045] The other end of the first roller body 2 is connected to one end of the first baffle 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com