Structurally-improved fence weaving machine

A fence weaving machine and improved structure technology, applied in mechanical equipment, sugarcane machining, etc., can solve problems affecting product aesthetics and yield, insufficient mechanization, affecting machine continuity, etc., to achieve simple procedures and avoid waste Effect of regularity, increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

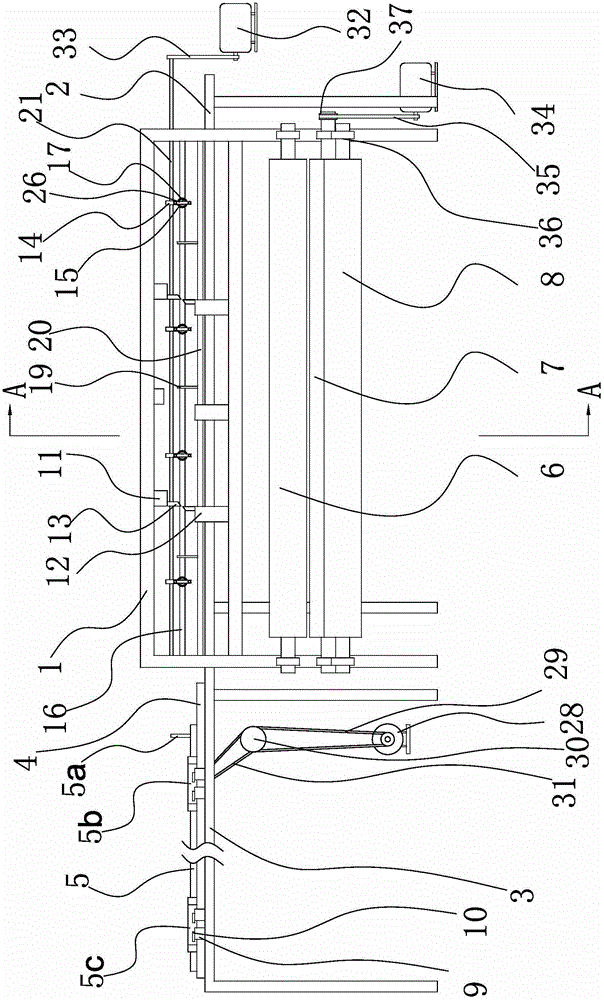

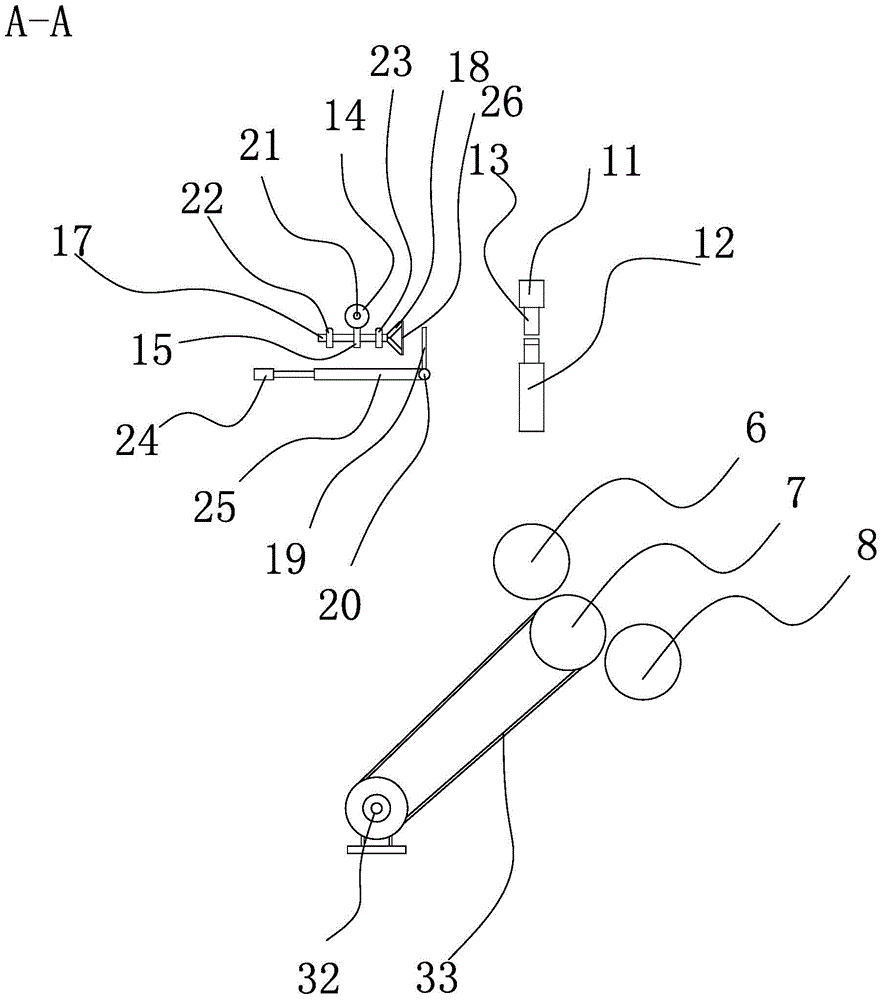

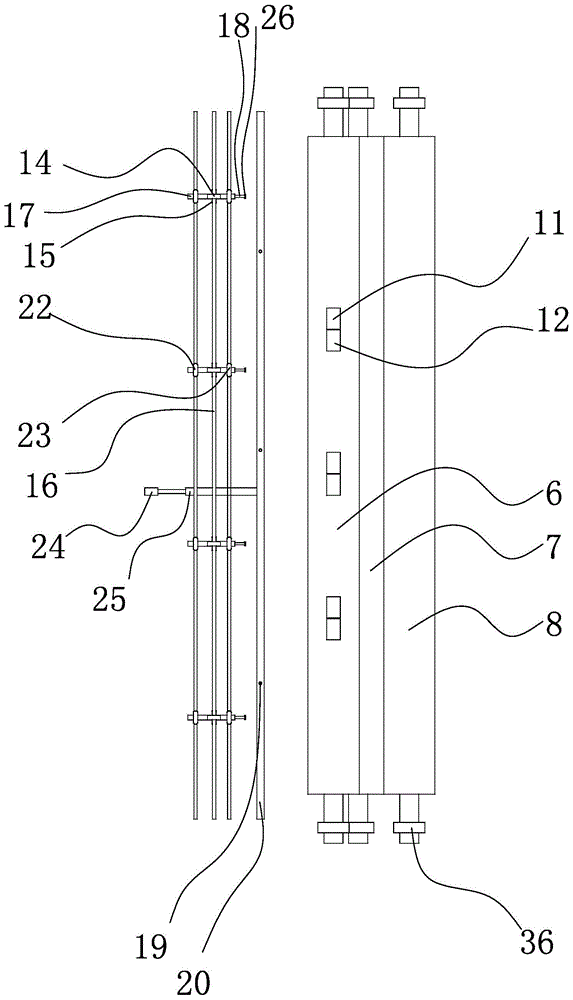

[0024] refer to figure 1 , figure 2 with image 3 , the present embodiment is a machine for weaving fences, including a frame 1, a feeding mechanism, a winding and weaving mechanism, a cutting mechanism and a discharging mechanism, as well as a motor that drives the above-mentioned mechanism, a cylinder 24 and an electric control device. Control devices include travel switches, relays, electric control valves, buttons, etc.

[0025]The feeding mechanism includes a slide bracket with a slide rail 4 and a pull rod 5 erected on the slide rail 4 . The sliding bracket is composed of a feeding rack 2 and a buffer rack 3. The feeding rack 2 is located at the frame 1, the buffer rack 3 is set on the side of the rack 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com