Water surface floating garbage collecting device and method

A technology of garbage collection and water surface floating, which is applied to the cleaning of open water surfaces, water conservancy projects, transportation and packaging, etc., can solve the problems of low efficiency, high labor intensity, high cost, etc., and achieve saving manpower and material resources, automatic cleaning, structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

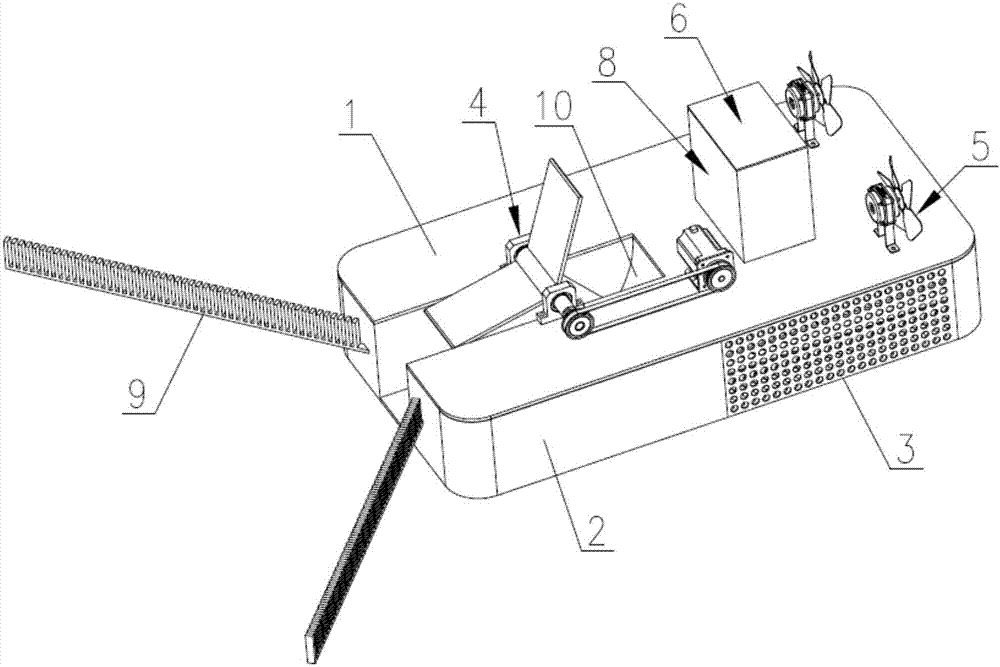

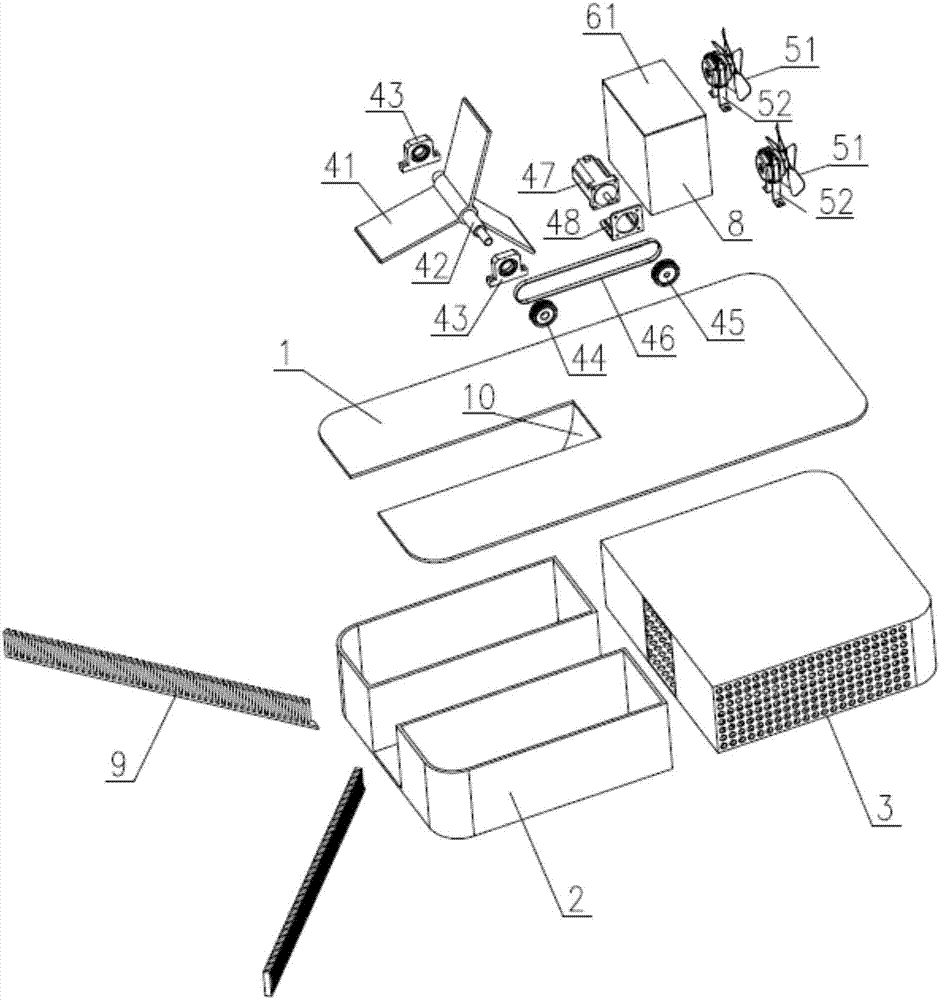

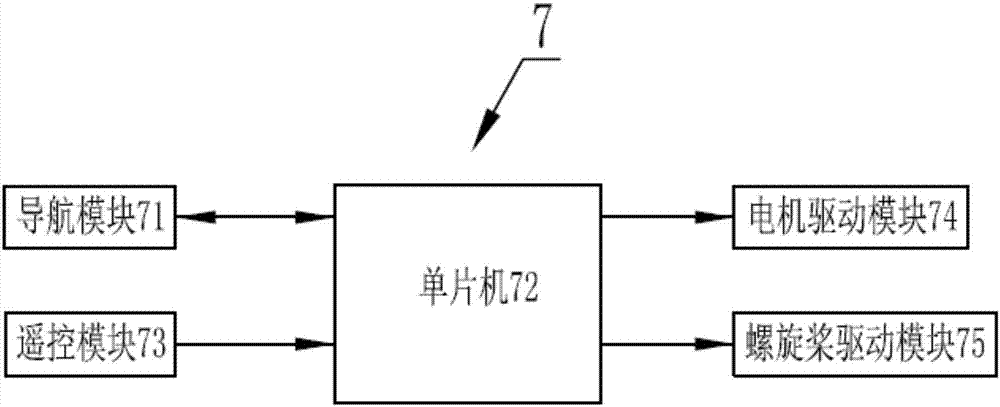

[0065] Such as Figure 1 to Figure 3 As shown, a floating garbage collection device on the water surface comprises a panel 1, a floating body box 2 fixedly installed at the bottom of the front section of the panel 1, a garbage storage box 3 fixedly installed at the bottom of the rear section of the panel 1, and a floating body box 3 fixedly installed at the bottom of the front section of the panel 1. The garbage collection mechanism 4, the power drive mechanism 5 fixedly installed on the rear section of the panel 1, and the power supply module 6 and the central processing module 7 fixedly installed on the panel 1 respectively, the power supply module 6 is used to control the garbage collection mechanism 4. The power drive mechanism 5 and the central processing module 7 supply power, and the central processing module 7 is used to send and receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com