Plate fixed-length cutting device

A cutting device and fixed-length technology, which is applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve the problems of low cutting efficiency and different cutting sizes of plates, and achieve improved cutting efficiency, uniform size, Realize the effect of cutting work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

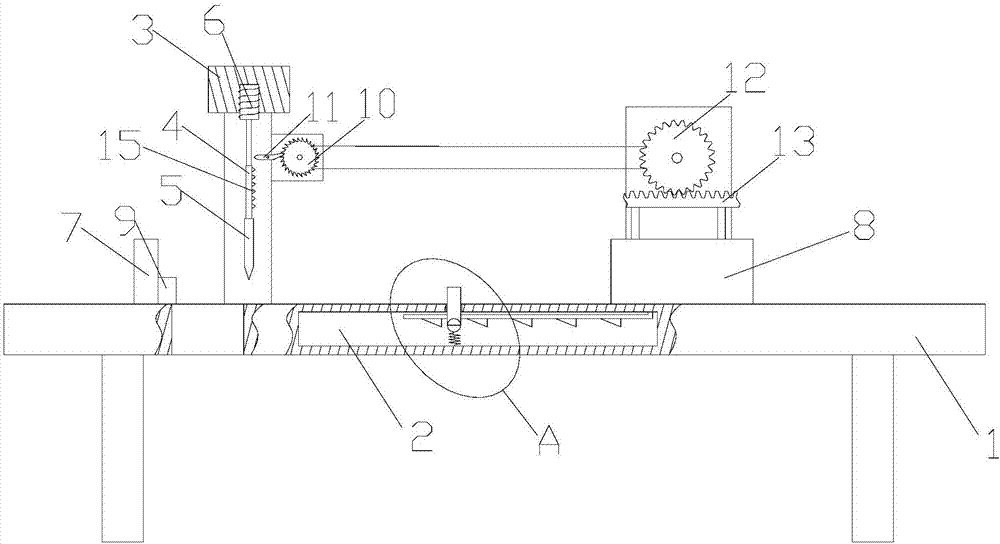

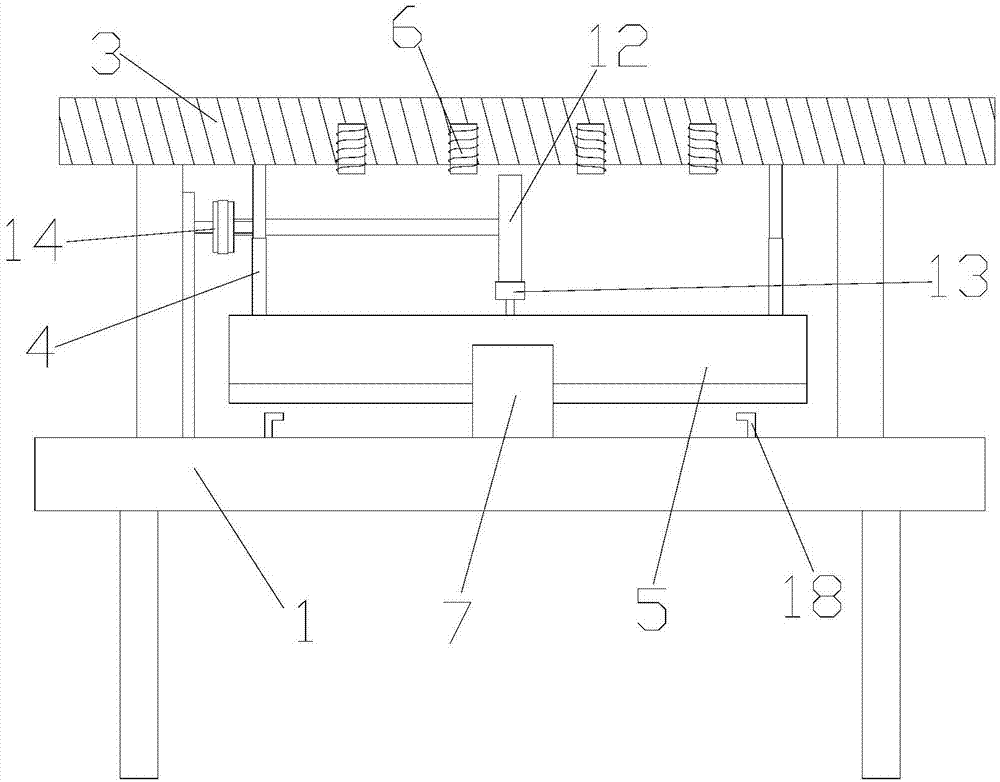

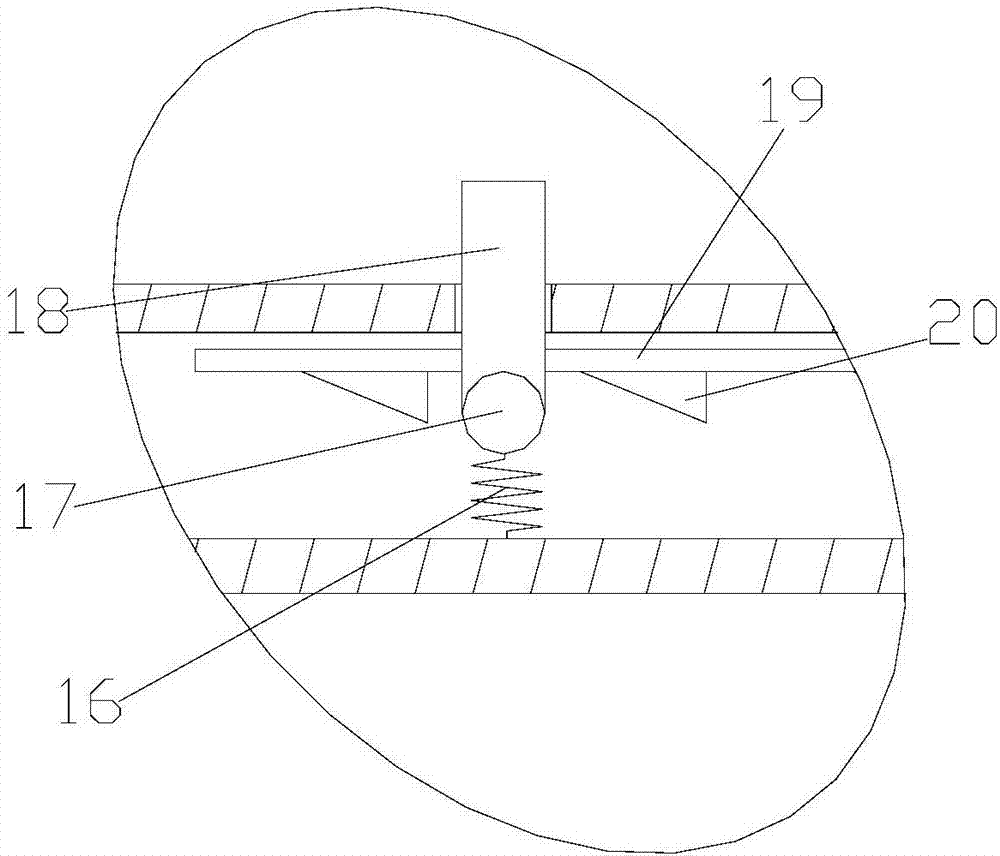

[0020] refer to Figure 1 ~ Figure 4 Shown: a plate fixed-length cutting device, including a worktable 1, a cavity 2 is opened in the worktable 1, a fixed-length feeding mechanism and a cutting mechanism are arranged on the working table 1, and the cutting mechanism drives the fixed-length feeding mechanism through a transmission mechanism Carry out feeding; Cutting mechanism comprises the gantry frame 3 that is fixedly arranged on the workbench 1 upper surface, and the crossbeam of gantry frame 3 is connected with cutting knife 5 by a plurality of telescopic rods 4, and telescopic rod 4 is two in the present embodiment, and telescopic rod 4 all include an inner rod connected to the beam of the gantry 3 and an outer hollow rod sleeved on the lower side of the inner rod, and the lower end of the outer hollow rod is connected with the cutting knife 5; the lower surface of the beam of the gantry 3 is along its axial direction A plurality of solenoids 6 are evenly distributed; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com