A kind of dust removal environmental protection equipment

An environmental protection equipment and dust technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of affecting the use time, easy to blow the dust bag, affecting the dust removal effect, etc., to improve the dust removal effect. The effect of gas dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

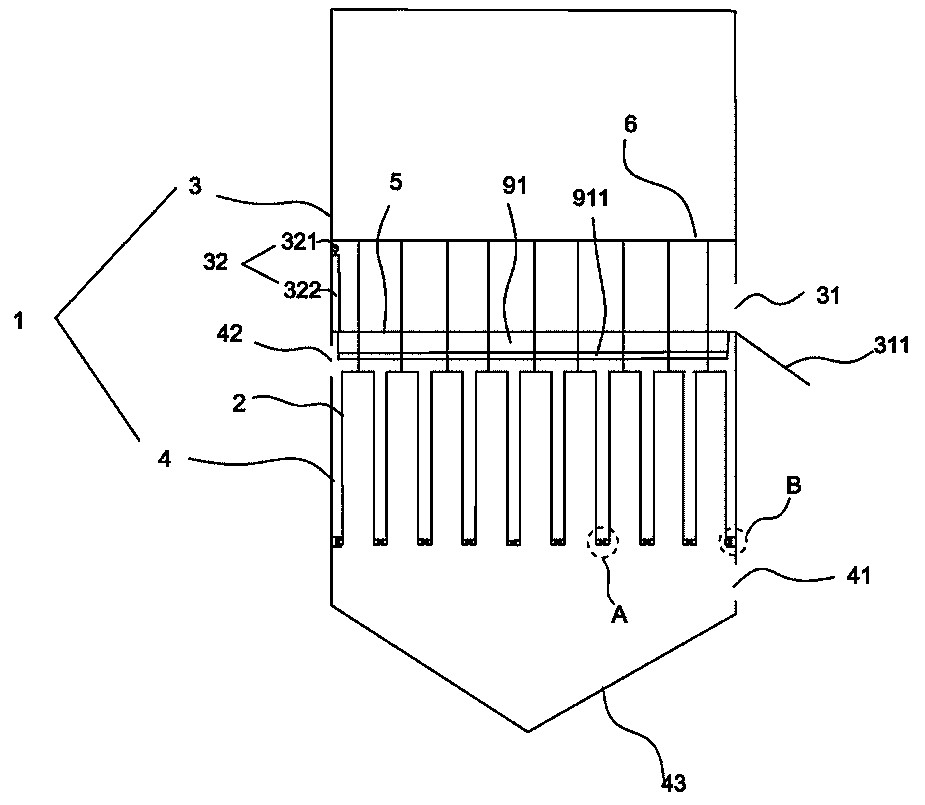

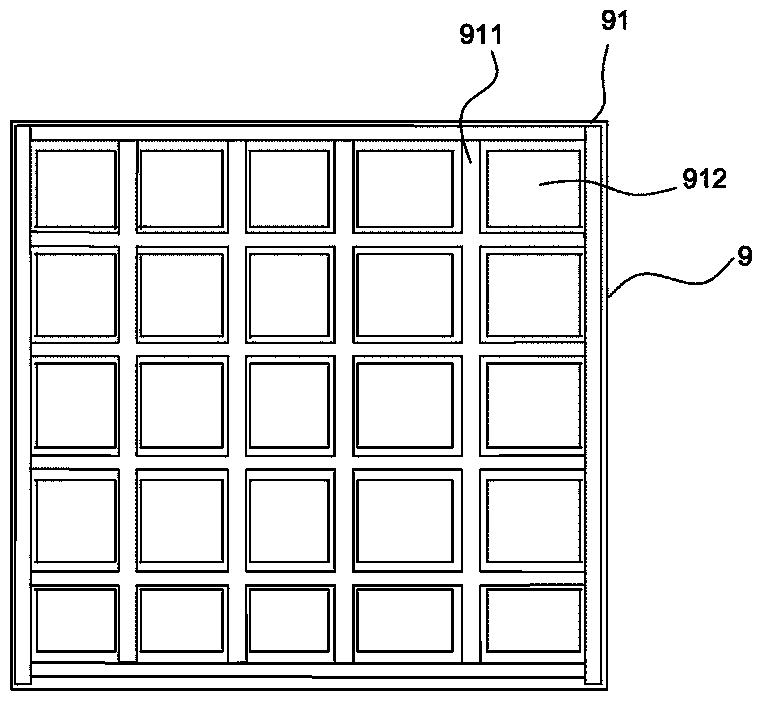

[0030] Such as Figures 1 to 6 The dust-removing environmental protection equipment shown includes a housing 1 and a plurality of dust-removing cloths 2 arranged in the housing 1 .

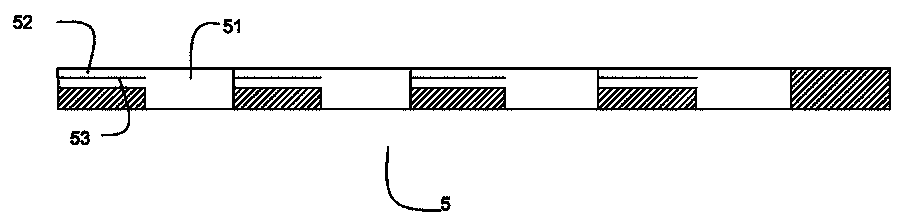

[0031] The casing 1 is divided into an upper casing 3 and a lower casing 4. The upper casing 3 is provided with a dust outlet 31, and the lower casing 4 is provided with an air inlet 41 and an air outlet 42. Between the upper casing 3 and the lower casing 4 A partition 5 is provided, and the partition 5 separates the dust removal of the gas from the cleaning of the dust bag to achieve a better gas dust removal effect. The partition 5 includes a plate portion 52 provided with a plurality of through holes 51 and a sealing sheet 53 which is arranged in the plate portion 52 and can seal the through holes 51. The through holes facilitate the entry and exit of the dust bag from the upper shell portion and the lower shell portion. During the cleaning process of the dust bag, the sealing sheet is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com