Inulin-enriched low-fat emulsion-type sausage and production method thereof

A technology of emulsified sausage and inulin, which is applied in the functions of food ingredients, food science, applications, etc., can solve the problems of lowering product quality, high fat content, and not reducing the quality of emulsified sausage, so as to increase yield and reduce cooking loss , the effect of maintaining texture and sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

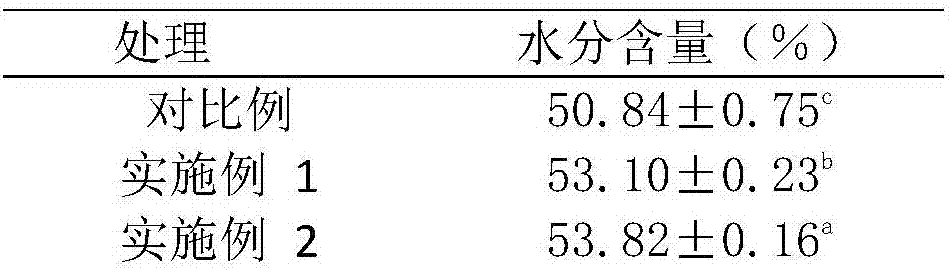

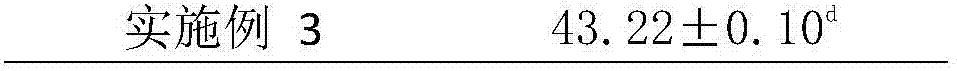

Embodiment 1

[0029] 1500g of trimmed lean meat and 410g of backfat, 671g of ice water, 24g of salt, 7.2g of polyphosphate and 137g of inulin were taken as raw materials. Put 1500g of trimmed pork hind leg lean meat into a chopping machine for chopping and mixing. The rotating speed of the chopping machine is 1500rpm, and the chopping time is 0.5min; then add 24g of salt and ice water of 2 / 3 weight, and adjust the rotating speed to 3000rpm, chopping time is 1min, stop chopping and let it stand for 2min to facilitate the dissolution of salt-soluble protein; add 410g of minced backfat, 7.2g of polyphosphate, the remaining 1 / 3 of ice water and inulin 137 grams, the speed of the chopping machine is 1500rpm, and the chopping time is 1min; finally, the whole minced meat system is chopped and mixed for 1-1.5min at the speed of 3000rpm; About 60g, the tightness should be enough to touch the sausage with two fingers; steam the semi-finished emulsified sausage in water, start timing when the water te...

Embodiment 2

[0031] 1500g of trimmed lean meat and 410g of backfat, 533g of ice water, 24g of salt, 7.2g of polyphosphate and 275g of inulin were taken as raw materials. Put 1500g of trimmed pork hind leg lean meat into a chopping machine for chopping and mixing. The rotating speed of the chopping machine is 1500rpm, and the chopping time is 0.5min; then add 24g of salt and ice water of 2 / 3 weight, and adjust the rotating speed to 3000rpm, chopping time is 1min, stop chopping and let it stand for 2min to facilitate the dissolution of salt-soluble protein; add 410g of minced backfat, 7.2g of polyphosphate, the remaining 1 / 3 of ice water and inulin 275 The rotating speed of the chopping machine is 1500rpm, and the chopping time is 1min; finally, the whole minced meat system is chopped and mixed for 1-1.5min at a rotating speed of 3000rpm; the stirred minced meat is enema, each intestine is about 15c long and weighs about 60g, the tightness should be enough to touch the sausage with two finge...

Embodiment 3

[0033]1500g of trimmed lean meat and 410g of backfat, 396g of ice water, 24g of salt, 7.2g of polyphosphate and 412g of inulin were taken as raw materials. Put 1500g of trimmed pork hind leg lean meat into a chopping machine for chopping and mixing. The rotating speed of the chopping machine is 1500rpm, and the chopping time is 0.5min; then add 24g of salt and ice water of 2 / 3 weight, and adjust the rotating speed to 3000rpm, chopping time is 1min, stop chopping and let it stand for 2min to facilitate the dissolution of salt-soluble protein; add 410g of minced backfat, 7.2g of polyphosphate, the remaining 1 / 3 of ice water and inulin 412 grams, the speed of the chopping machine is 1500rpm, and the chopping time is 1min; finally, the whole minced meat system is chopped and mixed for 1-1.5min at the speed of 3000rpm; About 60g, the tightness should be enough to touch the sausage with two fingers; steam the semi-finished emulsified sausage in water, start timing when the water tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com