Blueberry cultivation medium modifier, preparation method thereof and application of modifier

A technology of cultivation substrate and improver, which is applied in the direction of planting substrate, botany equipment and methods, applications, etc., can solve the problems of high logistics cost and high planting cost, and achieve the effect of reducing planting cost and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

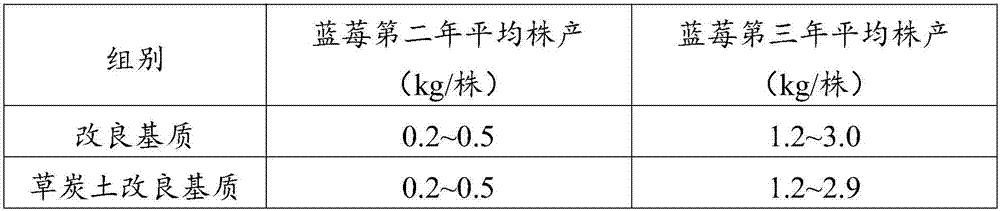

Image

Examples

preparation example Construction

[0038] The present invention also provides a preparation method of the blueberry cultivation substrate improver described in the above-mentioned technical scheme, comprising the following steps:

[0039] (1) mixing sulfur with the organic material according to the mass-to-volume ratio described in the above-mentioned technical scheme to obtain the fermentation raw material;

[0040] (2) inoculating the EM fermentation broth into the fermentation raw material to obtain a fermentation mixture, the moisture content of the fermentation mixture is 40% to 60%;

[0041] (3) performing aerobic fermentation on the fermentation mixture at a temperature of 25-35°C to obtain an aerobic fermented product;

[0042] (4) Anaerobically fermenting the aerobic fermented product under the condition of 25-35° C. to obtain a blueberry cultivation substrate improver.

[0043]The present invention mixes the sulfur and organic materials in the raw materials of the blueberry cultivation substrate impr...

Embodiment 1

[0056] In parts by weight, get 20 parts of cow dung, 20 parts of sheep manure, 40 parts of mushroom dregs, 10 parts of rice husk, 5 parts of sawdust and 5 parts of pine bark scraps and mix them to obtain organic materials. According to the quality of sulfur and the volume of organic materials than 0.5kg:1m 3 The ratio is mixed to obtain the first mixture. The mushroom dregs of shiitake mushrooms are from Fujian, mainly composed of sawdust and cottonseed hulls, and have a pH of 6.0. The rice husk, sawdust, and pine bark are first pulverized to a particle size of 5 mm and then mixed.

[0057] Take commercially available EM bacterial liquid, brown sugar and water in a ratio of 1:1:33 and mix to obtain EM fermentation liquid. The EM fermentation broth and the first mixture are sprayed on the surface of the first mixture according to the mass ratio of 1000:35, and 40 parts by weight of water are added to obtain a fermentation mixture with a water content of 40-60%.

[0058] Stac...

Embodiment 2

[0063] In parts by weight, get 40 parts of cow dung, 40 parts of Flammulina velutipes slag, 15 parts of rice husk and 5 parts of sawdust and mix to obtain organic material, according to the quality of sulfur and organic material volume ratio 1kg:1m 3 The ratio is mixed to obtain the first mixture. The sawdust is pulverized to a particle size of 3mm before mixing.

[0064] Take commercially available EM bacterial liquid, brown sugar and water in a ratio of 0.8:0.8:35 and mix to obtain EM fermentation liquid. The EM fermentation broth and the first mixture are sprayed on the surface of the first mixture according to the mass ratio of 800:32, and 20 parts by weight of water are added to obtain a fermentation mixture with a water content of 40-60%.

[0065] Stack the fermentation mixture into a stack with a height of 1.0-1.5m, and carry out aerobic fermentation at 25-35°C. When the temperature of the fermentation mixture reaches 40-50°C, roll over the material and re-stack it int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com