Three-dimensional software-based weldment modeling method

A 3D software and modeling method technology, applied in image data processing, special data processing applications, instruments, etc., can solve problems such as inaccurate drawing, low work efficiency, and difficulty in ensuring the correct size of parts, and achieve a wide range of applications. , high accuracy, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The modeling process of all parts of the shield machine cutter body weldment is as follows:

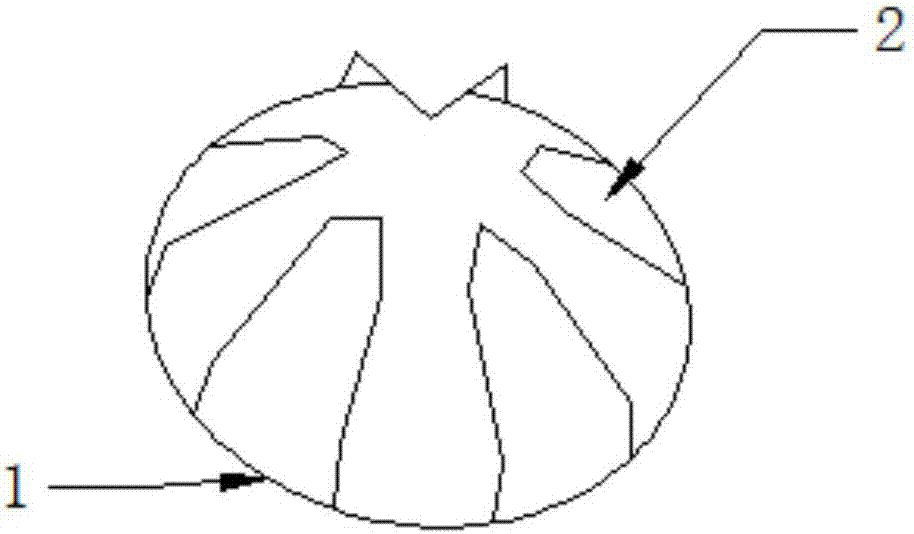

[0037] 1. Design the entire cutter body as one part, such as figure 1 As shown in , the three-dimensional model of the cutter body flange 2 and the base 1 is established first;

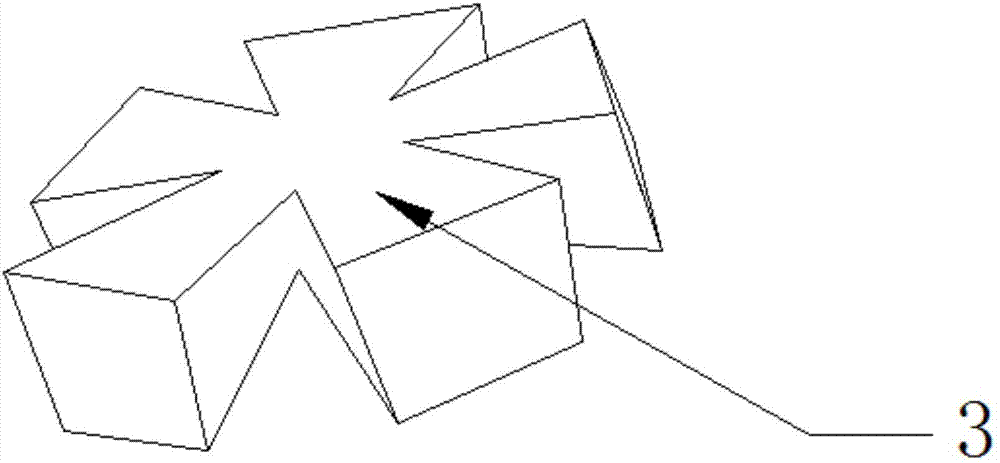

[0038] 2. If figure 2 As shown in Fig. 1, build a spoke box model other than the three-dimensional model of the cutter body flange and the base; insert the spoke box model into the base model part, position it constrainedly, and then use the Boolean operation method to combine it into one;

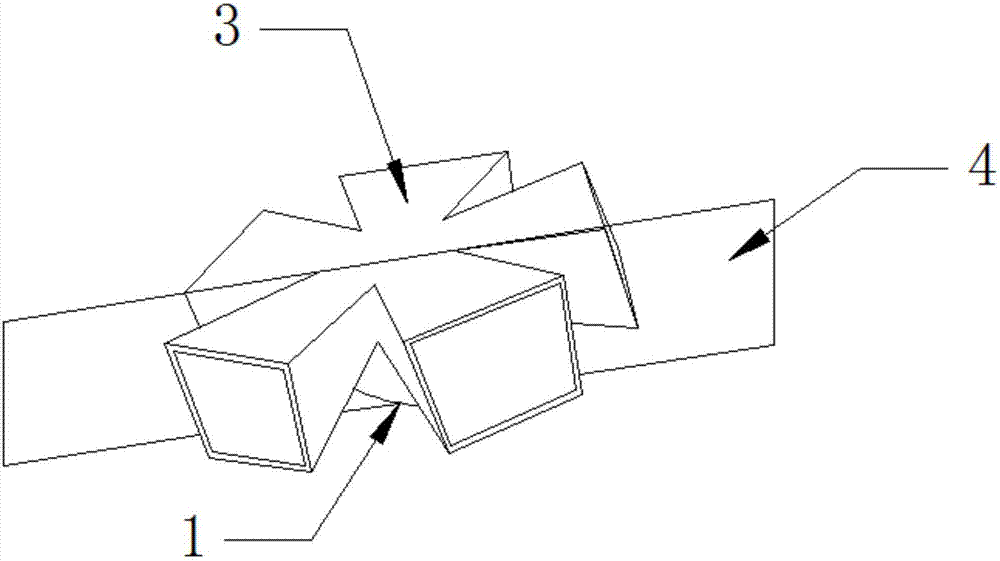

[0039] 3. If image 3 As shown in , select different surfaces according to the design requirements to extract the shell as a whole, and the thickness of the shell is divided according to the thickness of the plate;

[0040] 4. Establish the separation surface 4, and use the segmentation method to divide the whole part into spliced parts of different sizes. Its characteristic is that it is still a whole part, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com