Automobile exhaust tube connecting device

An automobile exhaust and pipe connection technology, which is applied in the field of auto parts, can solve problems such as loud noise and severe vibration of the whole vehicle, and achieve the effects of ensuring shock absorption, uniform force, and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

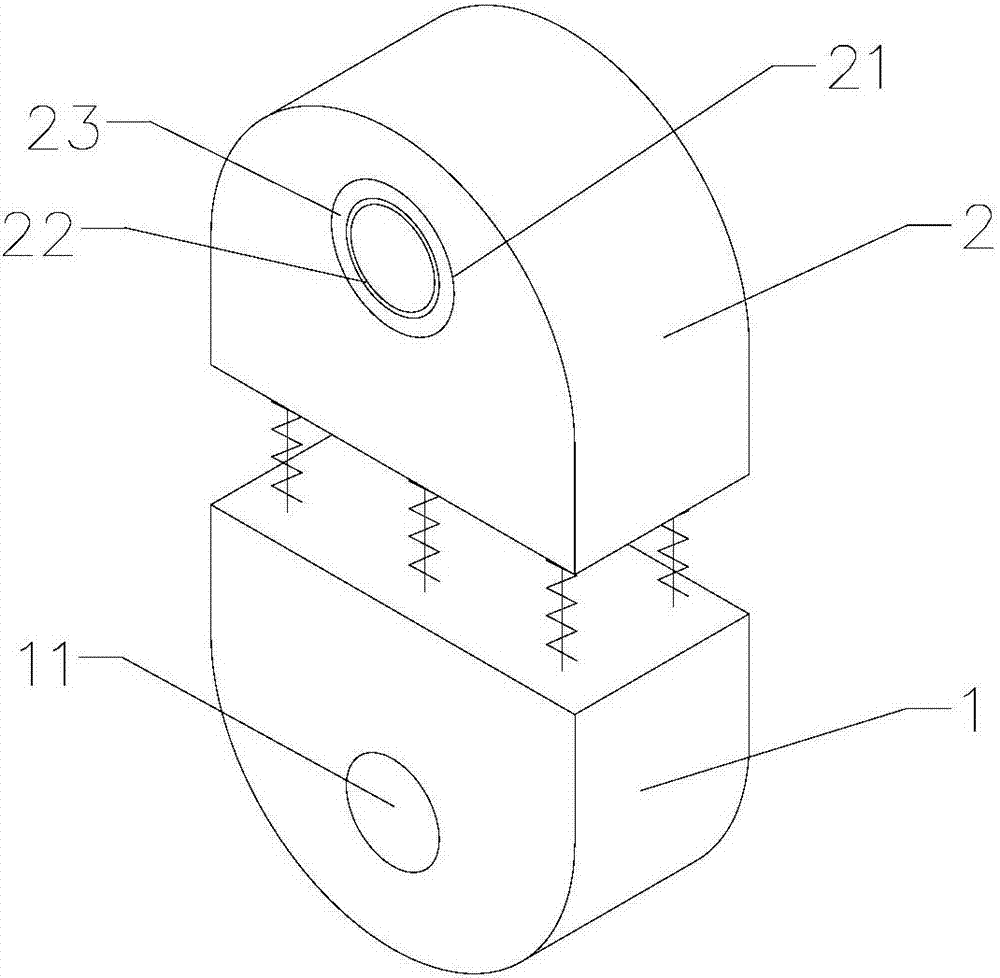

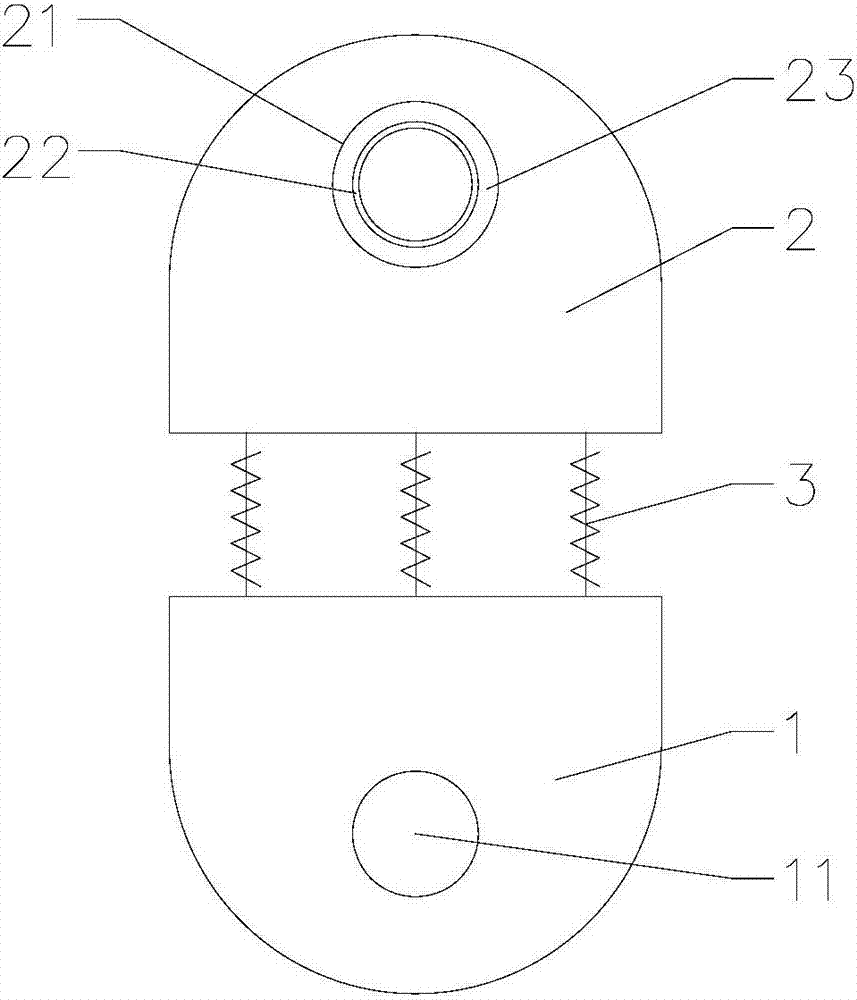

[0025] Such as Figure 1 to 3 As shown, the present invention provides an automobile exhaust pipe connecting device, which includes a fixing portion 1 and a connecting portion 2 arranged above the fixing portion 1. The fixing portion 1 is provided with a fixing hole 11 for fixed connection with the automobile chassis, and the connecting portion 2 A connecting hole 21 is provided. The connecting part 2 and the fixed part 1 are connected by a spring 3. The spring 3 provides elasticity, which acts as a shock absorber when the exhaust pipe vibrates, preventing the exhaust pipe from transmitting the vibration to the car chassis; connecting hole 21 There is a rubber collar 22 matched with the exhaust pipe. The exhaust pipe and the connecting part 2 are connected by the rubber collar 22. When the exhaust pipe collides with the rubber collar 22, it will not produce too much noise. To the effect of noise reduction; a shock absorber 23 is arranged between the rubber collar 22 and the con...

Embodiment 2

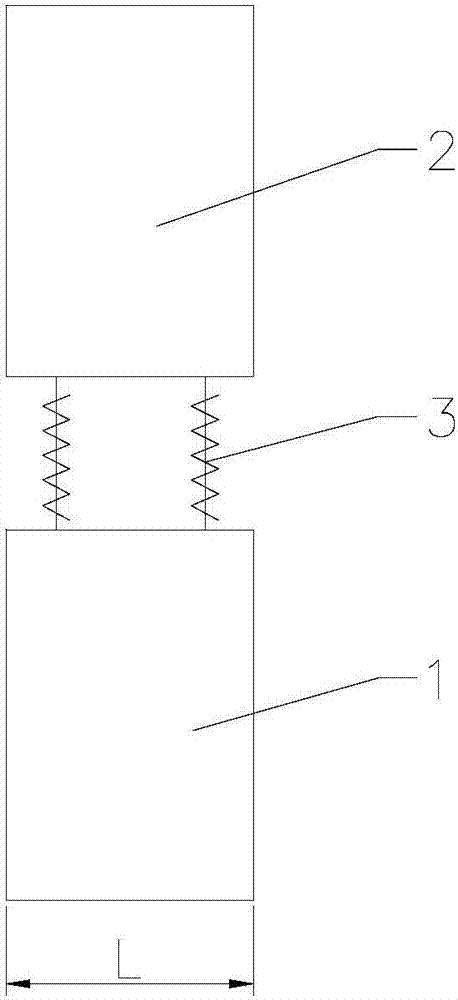

[0034] Such as Figure 4 As shown, the main difference between this embodiment and the first embodiment is that there are two fixing holes 11. There are two fixing holes 11, and the distance between the two fixing holes 11 and the connecting hole 21 is equal. The advantage of this arrangement is that the two fixing holes 11 can ensure the reliability of the connection between the automobile exhaust pipe connecting device and the automobile chassis, and the distance between the two fixing holes 11 and the connecting hole 21 is equal, so that the two fixing holes 11 An isosceles triangle is formed between the connecting hole 21 and the connecting hole 21, so that the force of the entire automobile exhaust pipe connecting device is more uniform, thereby ensuring the shock absorption effect of the automobile exhaust pipe connecting device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com