A kind of ship and method for mechanized harvesting kelp

A technology for kelp and boats, which is applied in the field of mechanized harvesting kelp, can solve the problems of difficult operation, compression of farming benefits, and difficulty in mechanization, and achieve the effects of reducing the probability of entanglement, avoiding missed collection of kelp, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

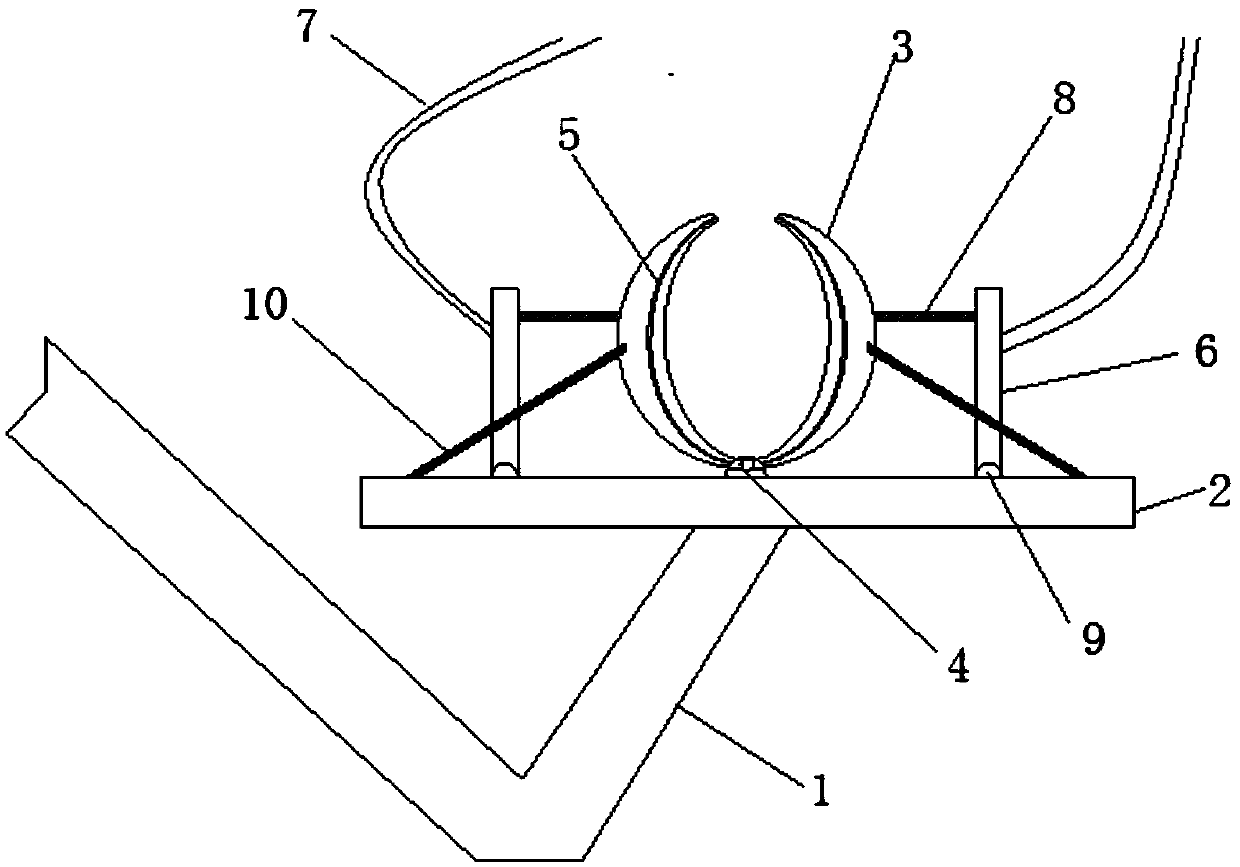

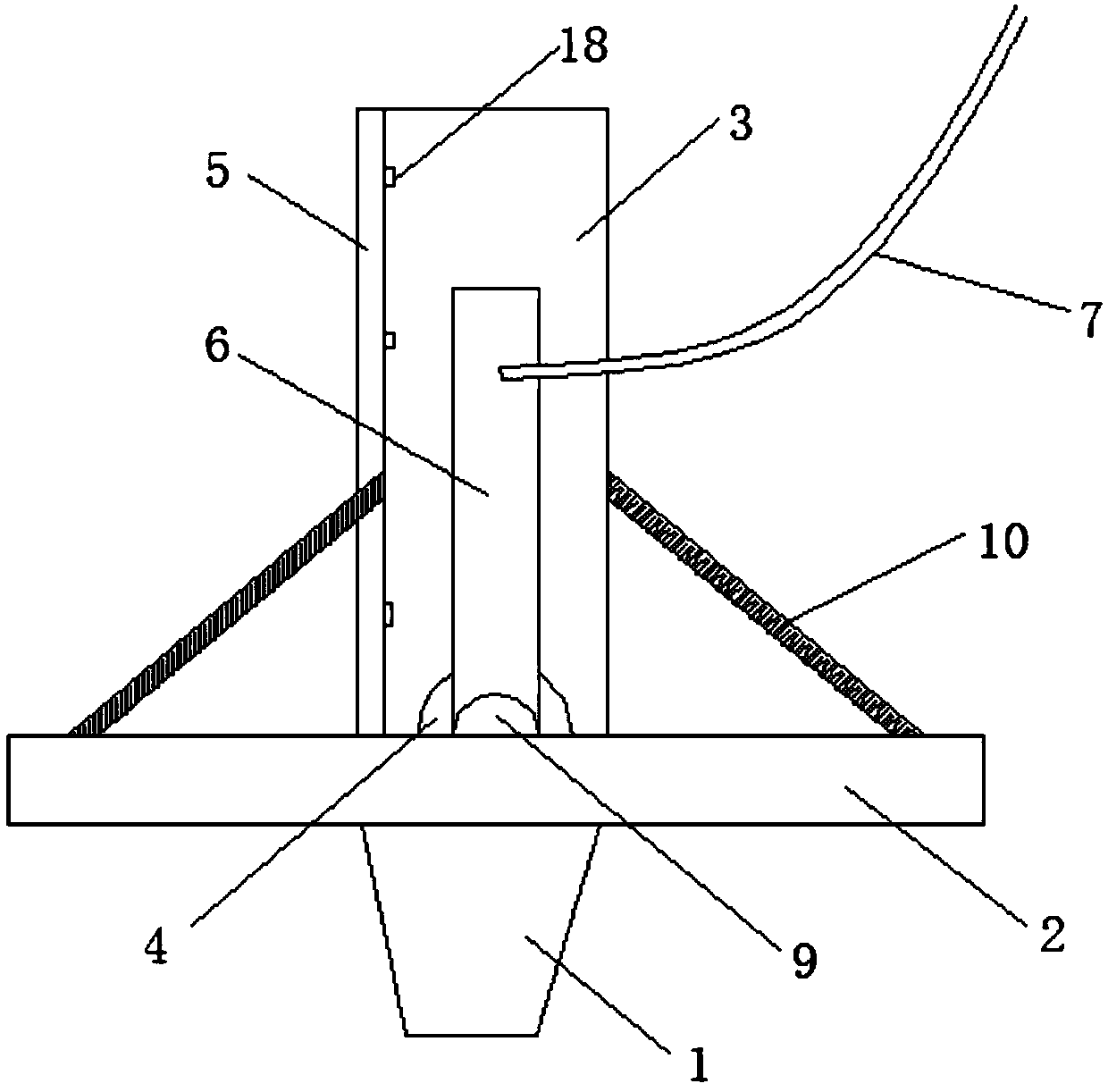

[0033] The invention provides a ship and method for mechanized harvesting kelp, such as Figure 6 As mentioned above, the ship and method can greatly improve the harvesting efficiency of kelp and reduce labor costs.

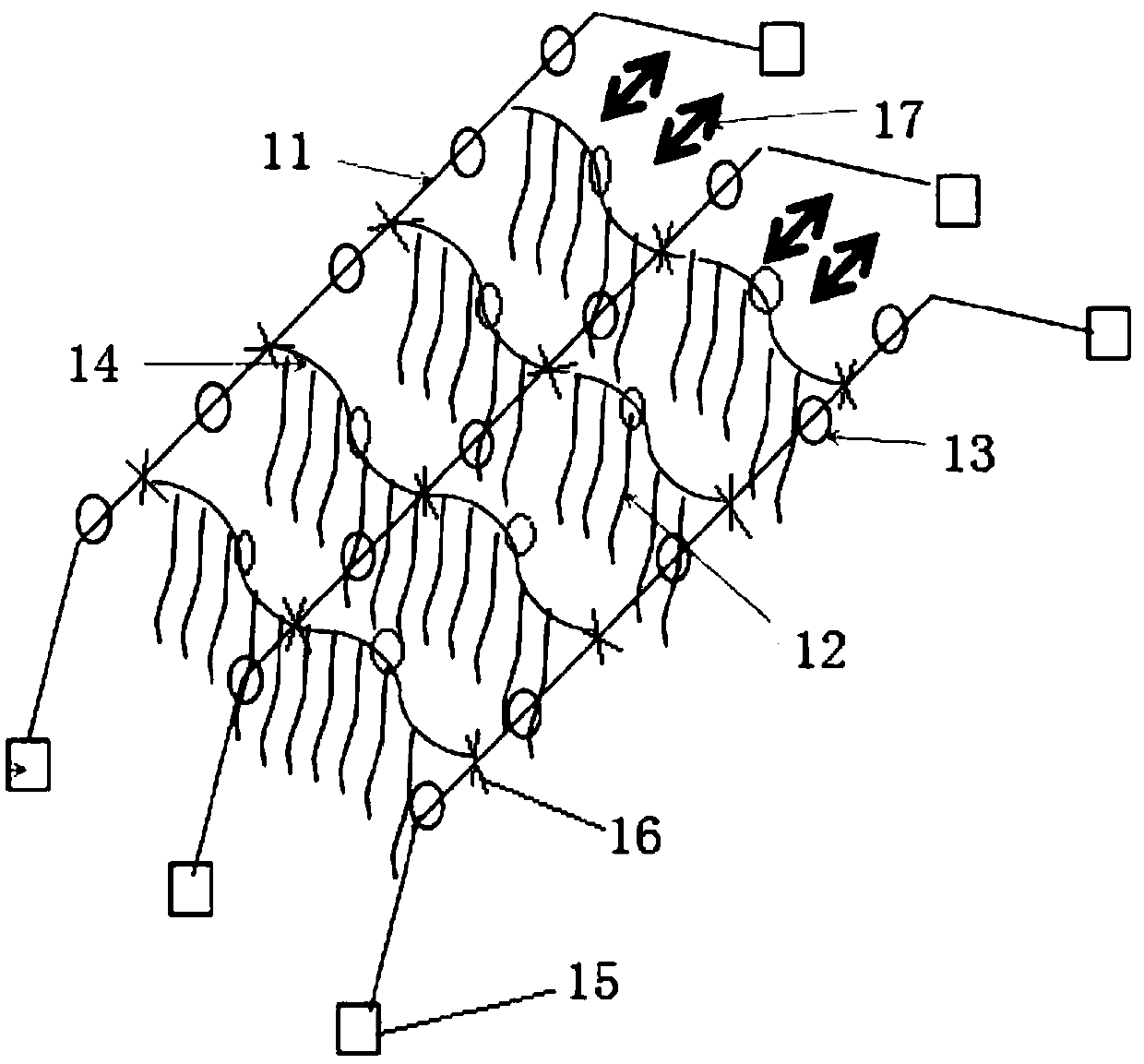

[0034] The new breeding pattern disclosed by the present invention is as Figure 4 , the kelp 12 is fixed on the kelp seedling rope 14, and the kelp seedling rope 14 is fixed on it longitudinally along the kelp raft frame stem rope 11 directly, and the sea current direction 17 is perpendicular to the kelp raft frame stem rope 11 direction. or as Figure 5 Shown, do not need kelp raft frame stalk rope 11, directly connect with kelp seedling rope 14 along the direction of former kelp raft frame stalk rope 11 longitudinally, and the buoyant ball 13 of different si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com