A door cover production line

A technology for the production of assembly lines and door pockets, which is applied in the direction of manufacturing tools and wood processing appliances, etc. It can solve the problems of difficulty in ensuring mutual space positions, high requirements for splicing or bonding precision, and low efficiency, and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The content of the present invention will be further described in detail below in conjunction with specific embodiments:

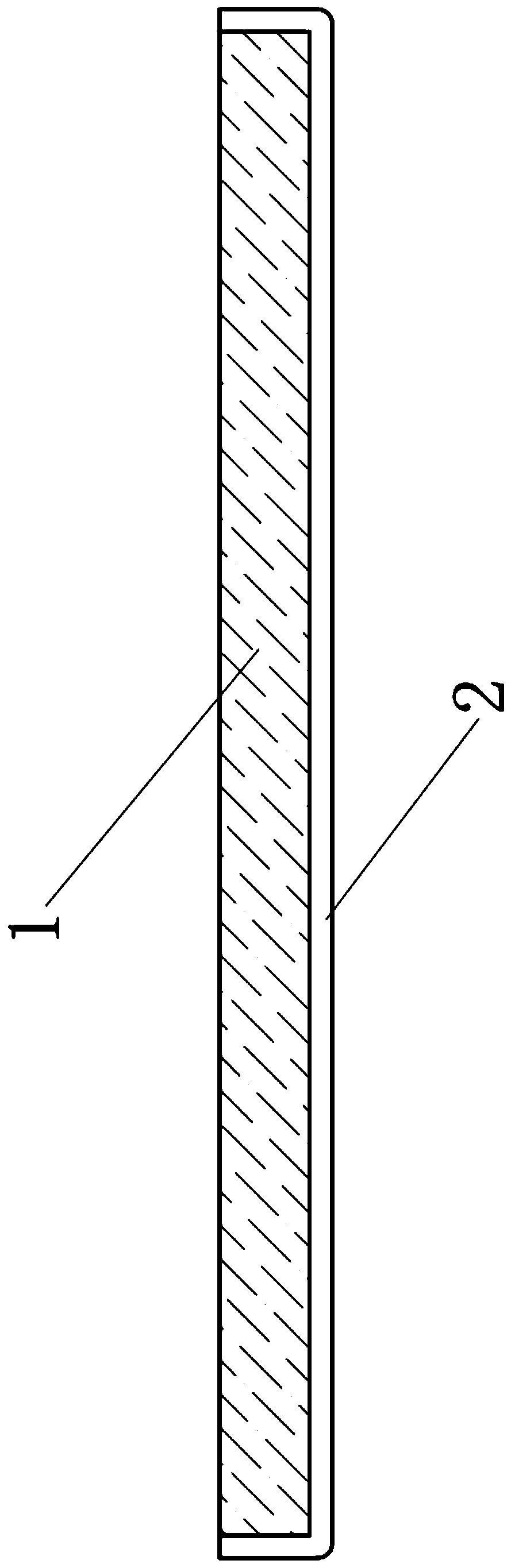

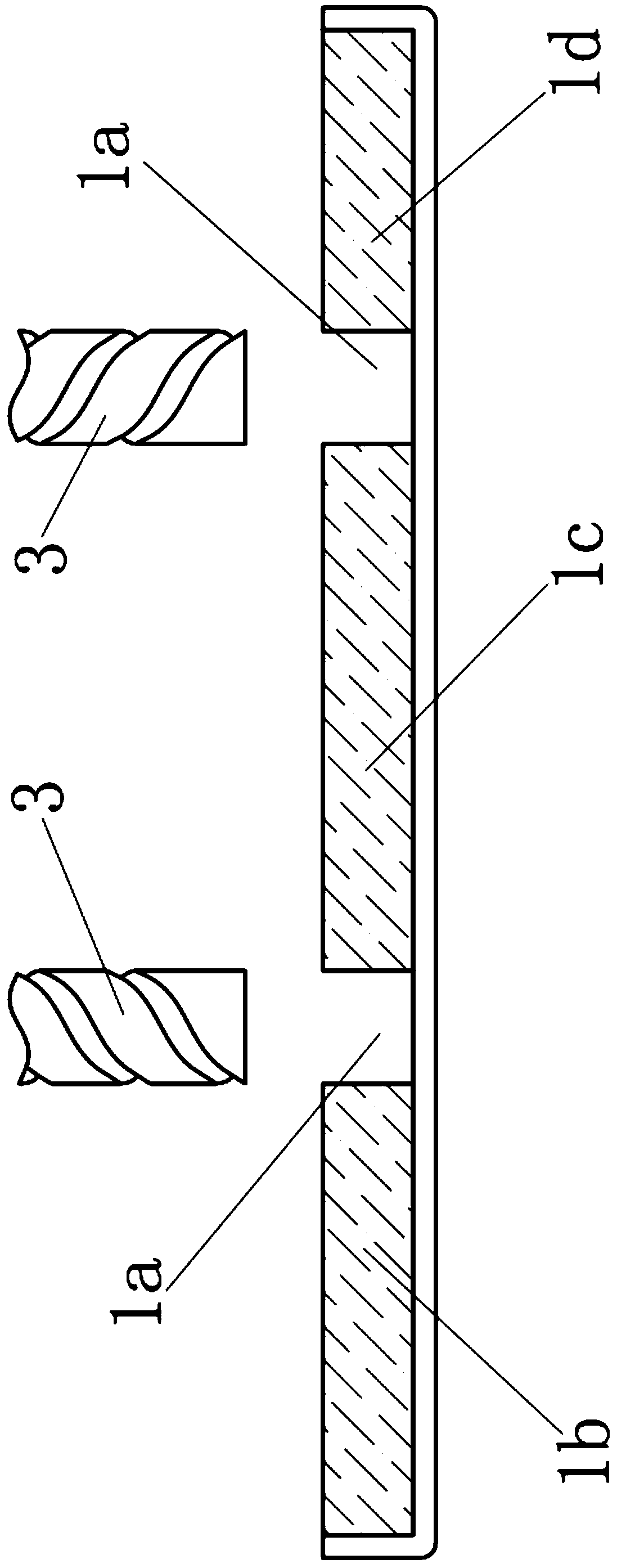

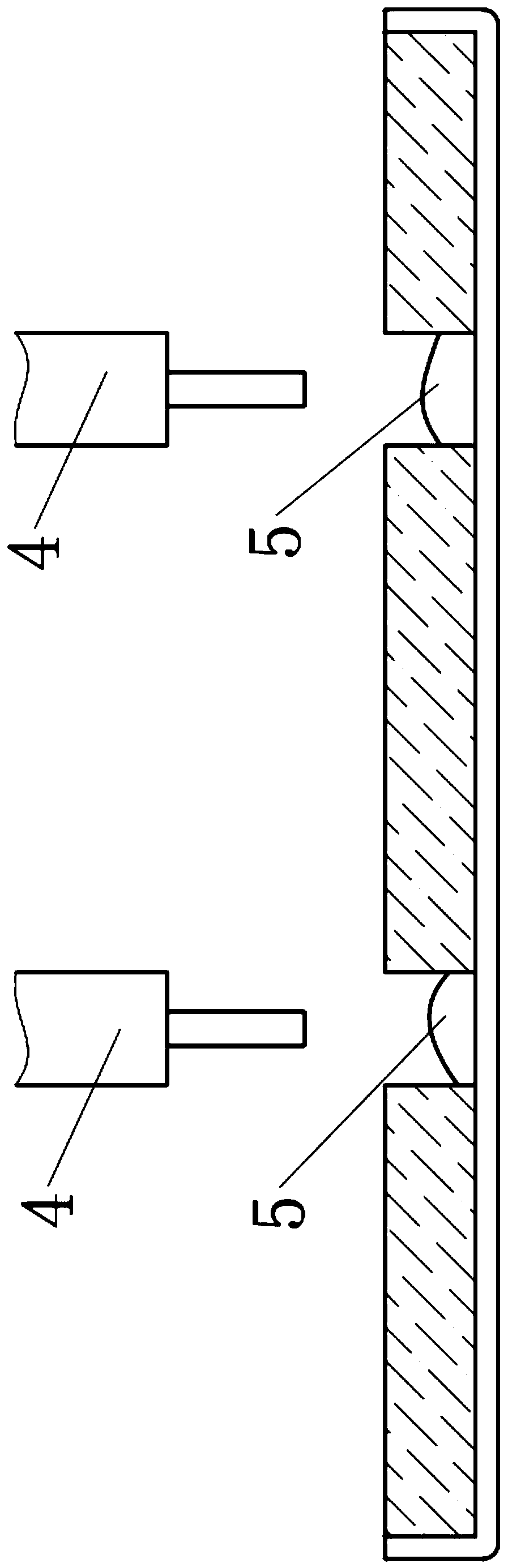

[0038] In order to achieve the purpose of the present invention, a door cover production line includes: a milling cutter 3, one side of the core plate 1 is pasted with a skin 2, and two milling cutters 3 are cut out on the side of the core plate 1 that is not pasted with the skin 2 Parallel grooves 1a, the width of the grooves 1a is not less than the thickness of the core board 1, the two grooves 1a divide the core board 1 into two sides of the first section 1b, the third section 1d and the second section 1c in the middle; The hose 4 is injected with glue into the groove 1a; the cambered wheel 10 is arranged below the first section 1b and the third section 1d, and the cambered wheel 10 has a convex arc profile in a cross-sectional view along its axis; The wheel 10 has a degree of freedom of movement in the vertical direction; the cambered wheel 10 chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com