Conveying mechanism of inflaming retarding high-resistance composite membrane cutting and perforating machine

A technology of high-barrier composite film and conveying mechanism, which is applied in metal processing and other directions, can solve the problems of simple structure and position deviation, and achieve the effects of improved perforation, convenient use and good conveying stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

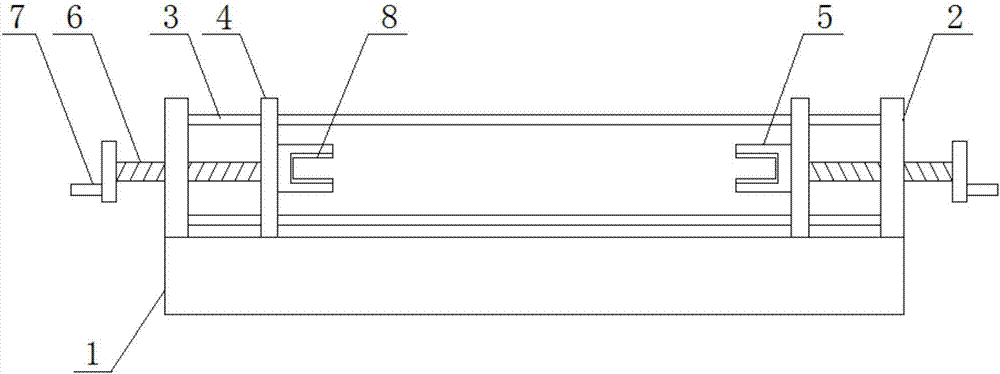

[0014] Such as figure 1 As shown, the present invention discloses a conveying mechanism for a flame-retardant high-barrier composite film material cutting and punching machine, including a workbench 1, and a vertical stand is fixed vertically at the left and right ends of the upper surface of the workbench 1, respectively. Plate 2, two smooth rods 3 are fixed horizontally between the two vertical boards 2, the two ends of the two smooth rods 3 are fixedly connected with the vertical boards 2 on both sides respectively, the two smooth rods 3 are distributed up and down, and the two vertical boards Two compression plates 4 are vertically arranged between the two, and the upper and lower ends of the compression plate 4 are movable and sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com