Motor tricycle tire bolt mounting and dismounting machine

A technology for motorized tricycles and loading and unloading machines, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve problems such as throwing off tires, traffic safety accidents, and the tightening force cannot meet the installation requirements, etc., and achieves good use effects , easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

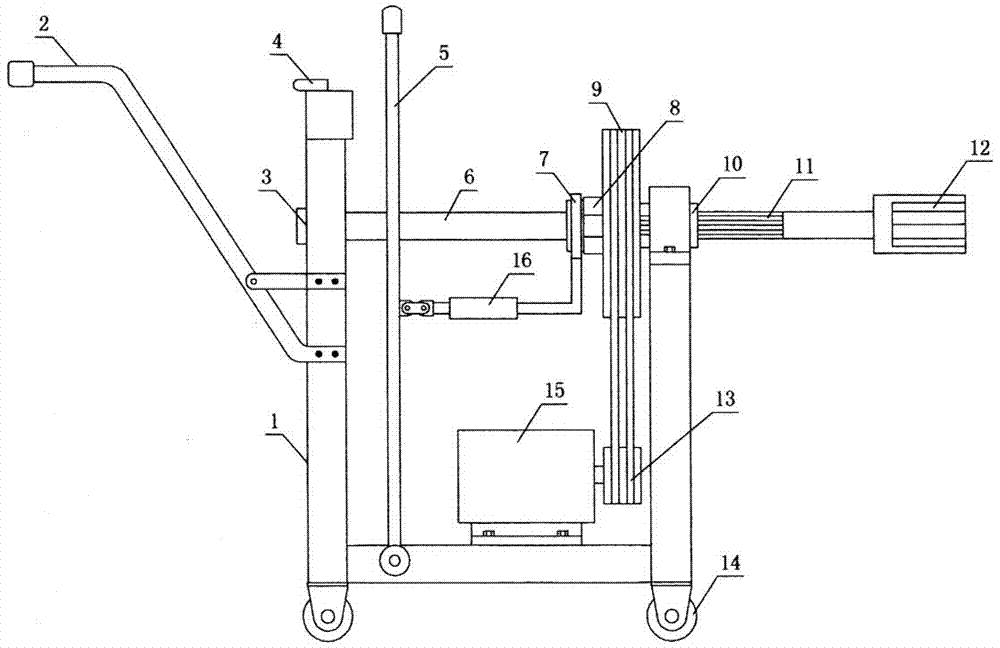

[0009] figure 1 The bottom side of frame 1 shown in is provided with motor 15, and motor pulley 13 is housed on the motor, and the front upper end of frame is provided with front axle hole 10, and the back upper end of frame is provided with rear axle hole 3, and axle hole is equipped with Bearing, central shaft 6 is housed in the front and rear shaft holes, and the central shaft is installed in the front and rear shaft holes of the frame upper end by bearings, the front end of the central shaft is shaped on a spline shaft 11, and the central shaft on the rear side of the spline shaft is provided with splines Axle sleeve 8, internal spline is shaped on in the inner edge of spline shaft sleeve, and the outside of spline shaft sleeve is provided with external spline, and power pulley 9 is housed on the external spline, and power pulley is provided with internal spline, and power pulley is provided with The inner spline is set on the spline shaft sleeve, and the rear end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com