FPGA-based end plug defect detection device and method

A defect detection and defect technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of difficult to detect workpieces, subjective influence of detection accuracy, high labor intensity, etc., to improve the degree of intelligence and automation, eliminate missed detection and error Detect defects, improve real-time and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

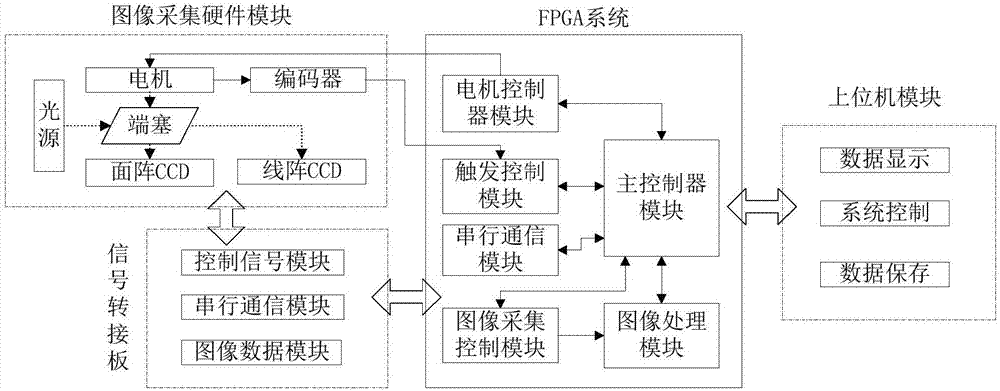

[0083] refer to figure 1 and figure 2 , an FPGA-based end plug surface defect detection device, including a rotating detection table, an image acquisition module, a signal adapter board 11, an FPGA main control module 12, and a host computer 13. The image acquisition module is connected to the input end of the signal adapter board 11 , the output end of the signal adapter board 11 is connected to the FPGA main control module 12 , and the FPGA main control module 12 is connected to the host computer 13 .

[0084] The rotary detection platform includes a detection platform 8 arranged horizontally, a motor 10 and a decoder; the detection platform 8 is connected to the motor 10, and the motor 10 drives the detection platform 8 to rotate at a constant speed, the motor 10 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com