Multistage filtering device used for extractor hood

A range hood and stage filtration technology, which is applied in the direction of removing oil fumes, applications, household stoves, etc., can solve problems such as complex structures, and achieve the effect of improving the oil filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

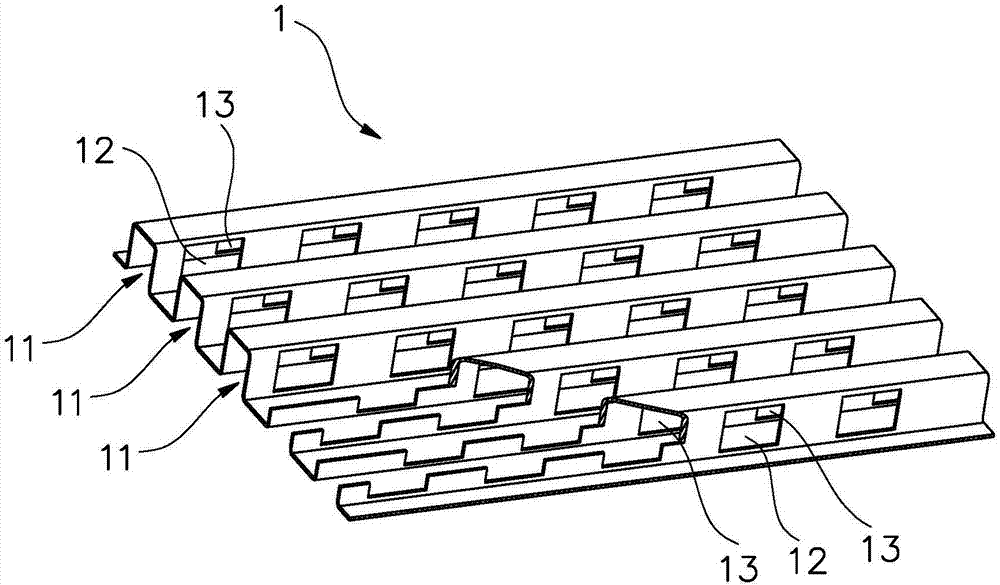

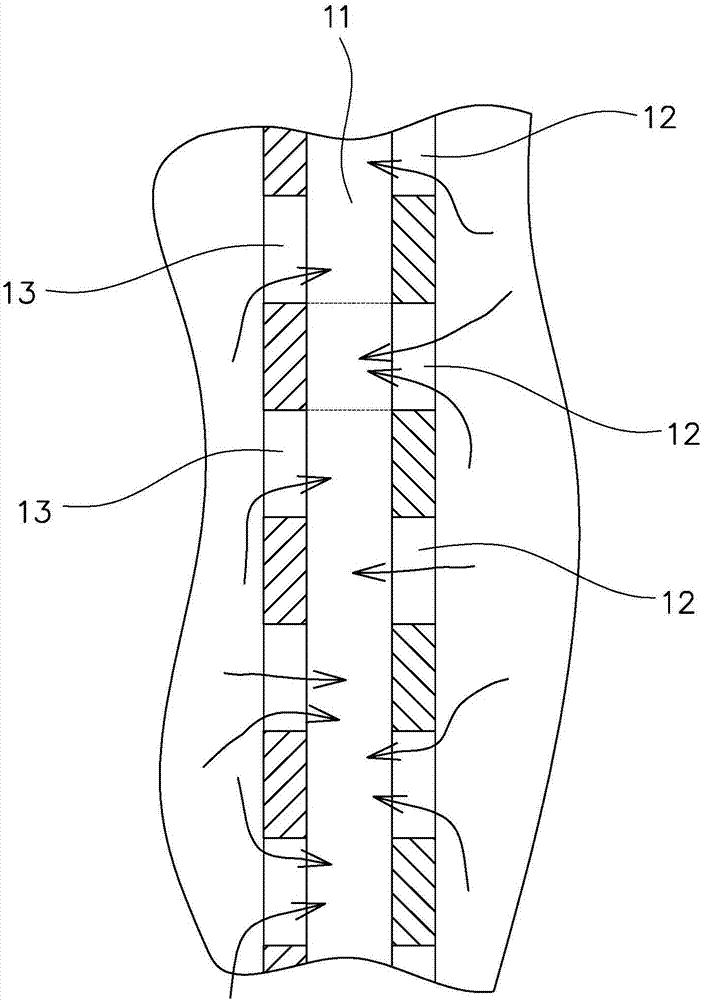

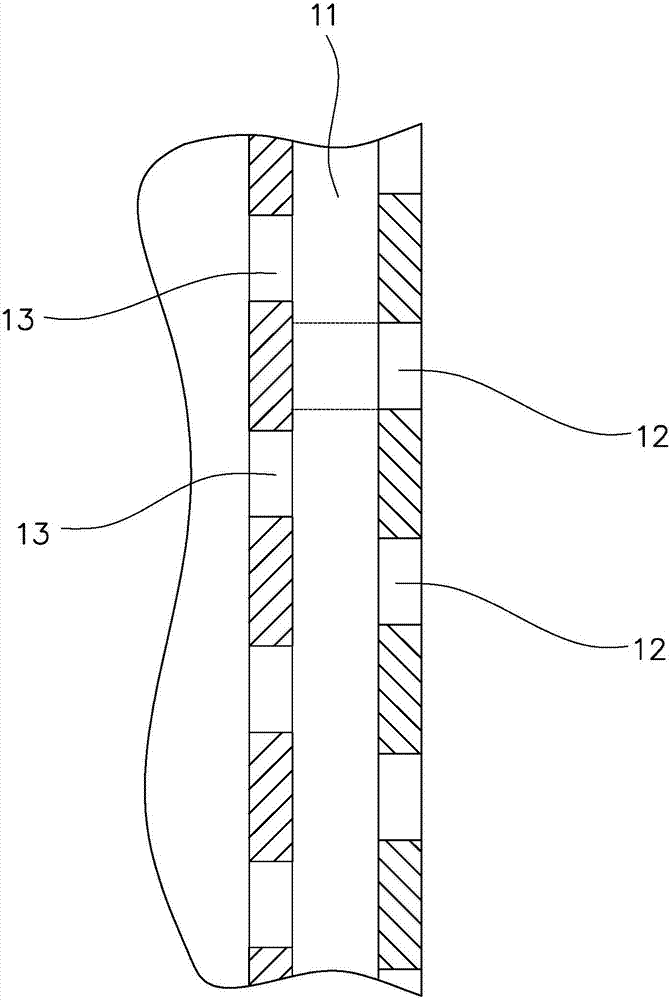

[0021] Such as figure 1 As shown, the multi-stage filter device used for range hoods in this embodiment includes an oil filter plate 1, and the oil filter plate 1 has a U-shaped oil filter groove 11 formed by indenting toward the same side of the oil filter plate, and the U-shaped oil filter groove 11 are parallel to each other and distributed at intervals in turn, and the two opposite side walls of the U-shaped oil filter groove 11 are all vertically arranged. A first oil filter hole 12 and a second oil filter hole 13 are respectively opened on two opposite side walls of the U-shaped oil filter groove 11, and the first oil filter hole 12 and the second oil filter hole 13 are all along the U-shaped oil filter groove 11. The length direction of the distribution is spaced apart and staggered from each other.

[0022] In this embodiment, the first oil filter hole 12 and the second oil filter hole 13 are completely staggered in the length direction of the U-shaped oil filter groo...

Embodiment 2

[0027] Such as Figure 6 As shown, the first oil filter holes 12 and the second oil filter holes 13 are distributed in clusters at intervals, and each cluster of the first oil filter holes 12 and the second oil filter holes 13 includes at least three small round holes, And the projections of any first oil filter hole 12 and any second oil filter hole 13 on the same vertical plane do not overlap.

[0028] The oil fume filtering process of the oil filtering device of this embodiment is the same as that of Embodiment 1, and will not be further described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com