Folded vacuum noise reduction glass window

A glass window and glass technology, applied in parallel glass structures, windows/doors, door/window applications, etc., can solve the problems of high noise, cumbersome glass replacement, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

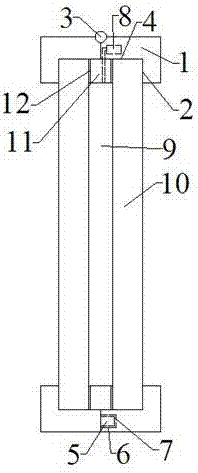

[0018] Embodiment 1, the embodiment of the present invention includes: a folding vacuum noise-reducing glass window, including: two frames 1, two frames 1 are provided with a groove 2 opposite to each other symmetrically, and the two grooves 2 are combined A glass installation groove 4 is formed, and two glasses 10 are installed in the glass installation groove 4, and the glass installation groove 4 is used for installing the two glasses 10.

[0019] A partition frame 11 is installed between the two glasses 10, and a sealing layer 12 is installed between the partition frame 11 and the two glasses 10, so that the sealing between the partition frame 11 and the glasses 10 is better .

[0020] An air extractor 8 is installed on one of the frames 1, and the conduit on the air extractor 8 runs through the partition frame 11 and is connected with the vacuum space 9 surrounded by the partition frame 11 and the glass 10. , the air extractor 8 is used for evacuating the vacuum space 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com