Lattice type buttress type retaining wall with ground anchor and construction method

A lattice type and buttress type technology, which is applied in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve the problem of increasing the area of the retaining wall, and achieve the effect of small area, low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

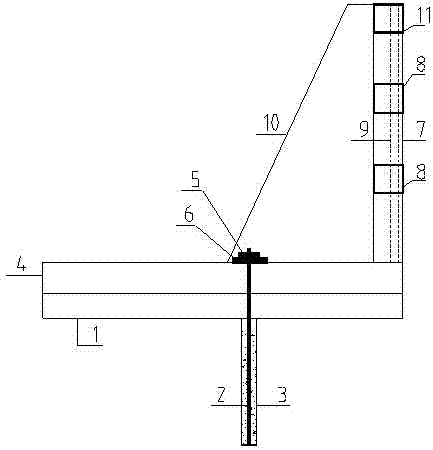

[0018] For further understanding content, characteristic and effect of the present invention, below in conjunction with example and accompanying drawing, describe in detail as follows: figure 1 As shown, the lattice type buttress retaining wall with ground anchor includes ground beam 1, anchor rod 2, anchor section 3, bottom plate 4, bolt 5, backing plate 6, column 7, beam 8, wall panel 9, Buttress 10 and crown beam 11, first set out the line to locate the slot section of ground beam 1, excavate ground beam 1 at the design position of ground beam 1 to open a slot, and then position anchor rod 2 in the slot section of ground beam 1 According to the design angle of the anchor rod 2, a hole is opened in the groove section of the ground beam 1, the anchor rod 2 is placed in the hole, and the anchorage section 3 is formed by grouting; Wall panel 4 steel bars and buttress 10 steel bars, pour concrete, after the concrete strength of ground beam 1 and base plate 4 reaches the design r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com