Super-large-diameter assembled hollow pile and assembling method thereof

A super-large-diameter, hollow pile technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as difficult transportation, difficult pouring of pile bottoms, and high heat of concrete hydration, so as to achieve convenient storage and transportation, strength assurance, The effect of quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention. .

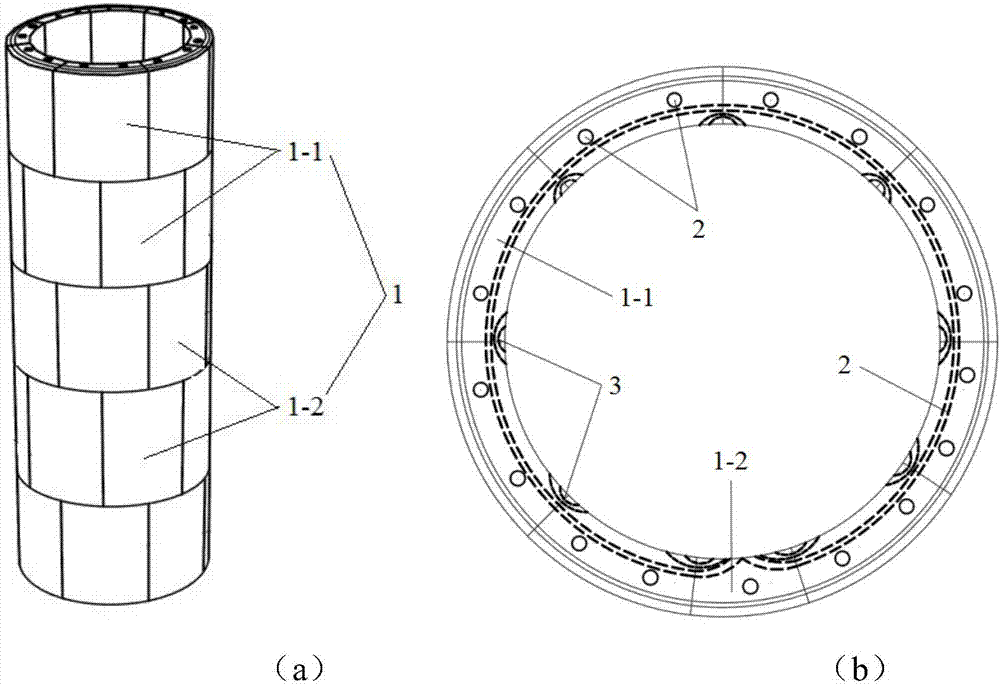

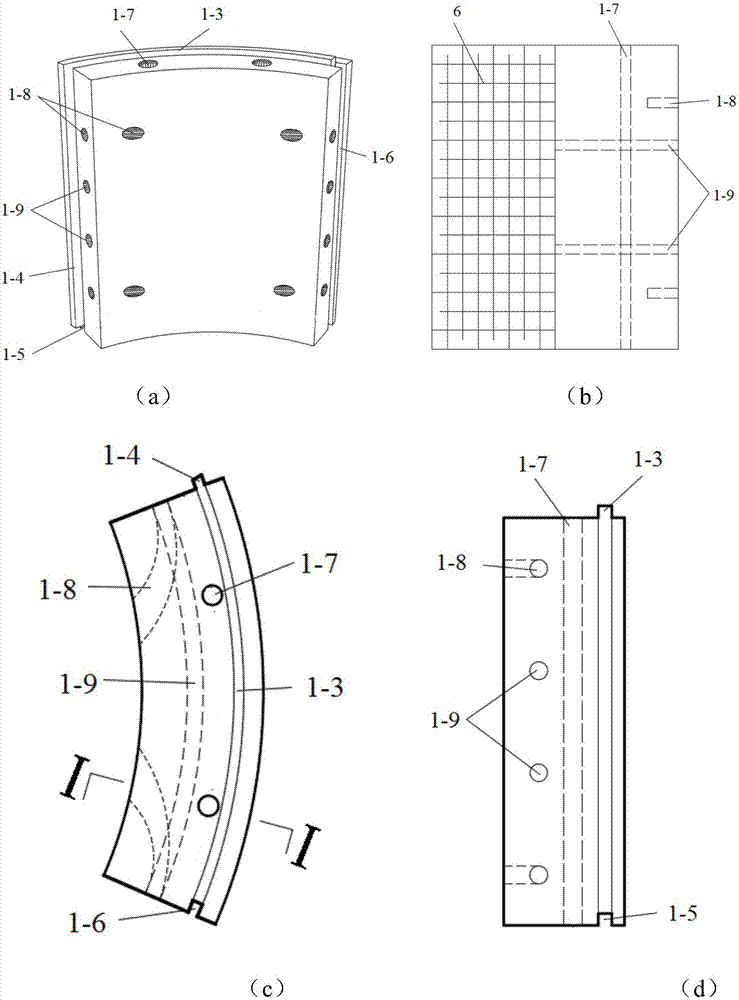

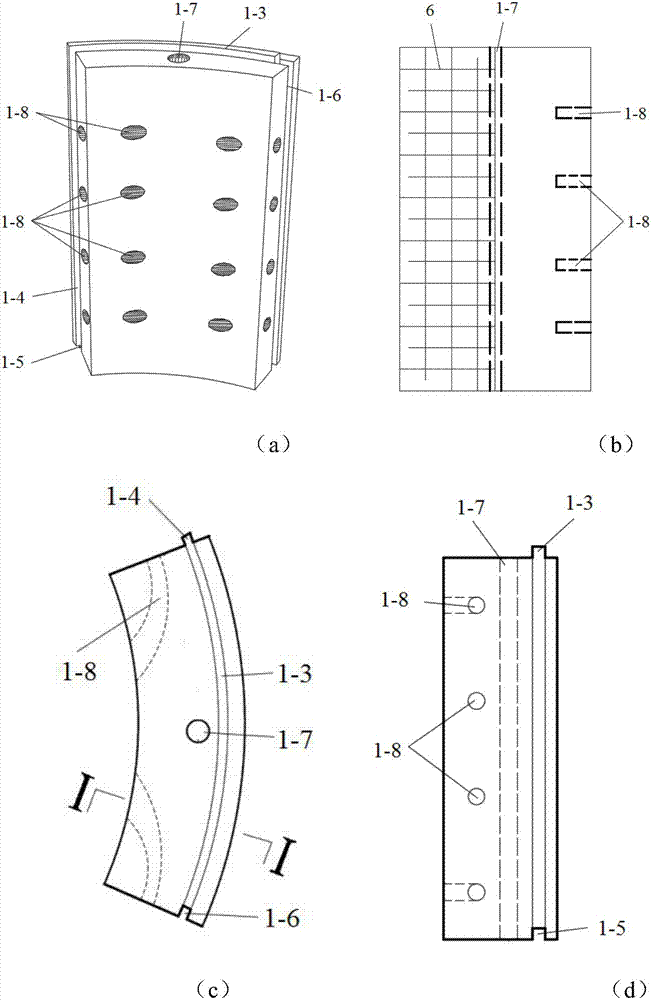

[0042] Such as figure 1 As shown, the present invention discloses a super-large-diameter assembled hollow pile, which includes a plurality of pile pieces 1, the pile pieces are arc-shaped, and a plurality of pile pieces 1 are spliced along the ring to form a closed ring-shaped splicing pile section. The spliced pile sections are spliced along the axial direction to form an assembled hollow pile; the splicing gaps in the adjacent circular spliced pile sections are staggered from each other; the axial joints between the connected pile sections are avoided, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com