Continuous hot galvanization equipment and continuous hot galvanization method for hot rolled strip steel

A technology for hot-rolled strip steel and hot-dip galvanizing, which is applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of high furnace temperature, poor furnace operating environment, long furnace length, etc. The effect of length shortening, current penetration depth is small, and space occupation is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

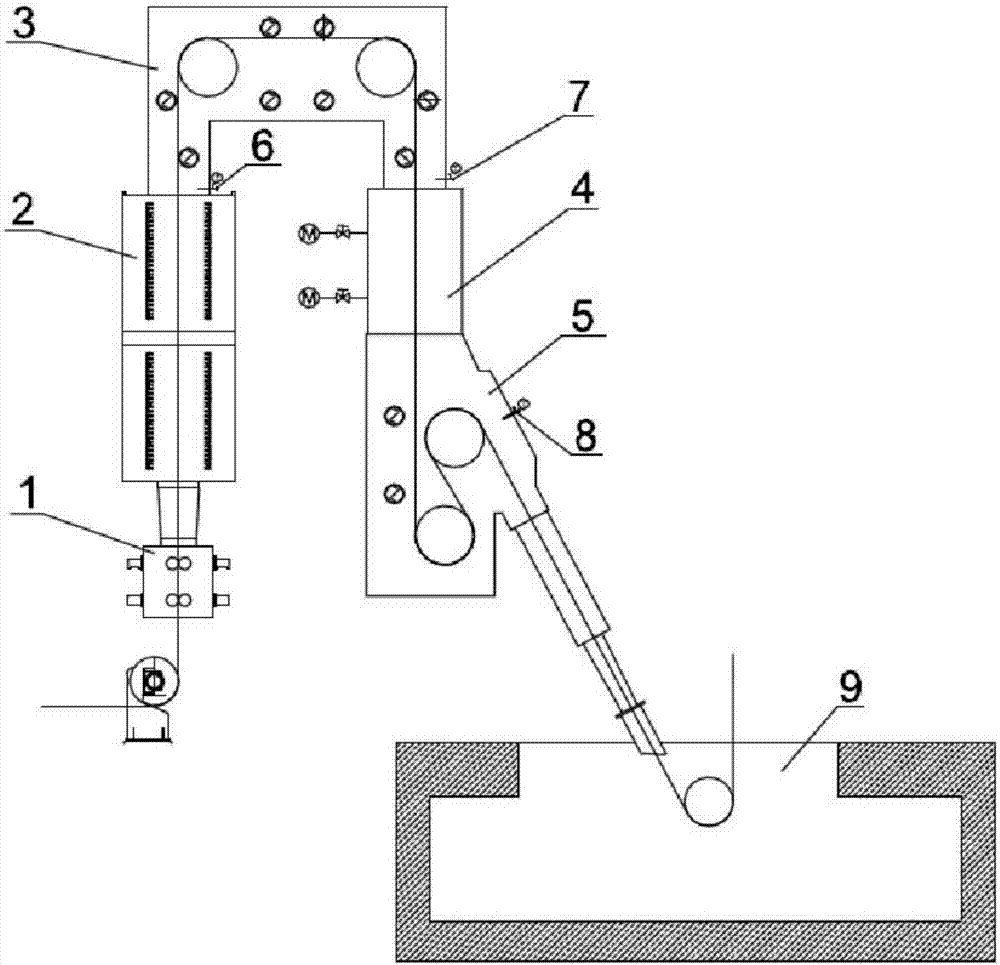

[0026] figure 1 is a schematic diagram of a hot-rolled strip continuous hot-dip galvanizing plant according to the present invention. As shown in the figure, in one embodiment of the continuous hot-dip galvanizing equipment for hot-rolled strip steel according to the present invention, the hot-rolled strip steel after on-line pickling enters the heating section 2 from the entrance sealing section 1, and is heated in a reducing atmosphere. Heating to above 500°C fully reduces the thin layer of iron oxide on the surface of the strip steel, and then passes through the soaking section 3 and cooling section 4 to keep the strip steel temperature at about 475°C, passes through the exit section 5, and then enters the zinc pot 9 for galvanizing. The temperature entering the zinc pot should be adjusted according to the thickness and variety of the strip steel. Wherein, the heating section 2 is an induction heating section, the soaking section 3 is an electric heating soaking section, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com