Deoxidation method of naphtha raw material

A naphtha and raw material technology, applied in the field of naphtha reforming process, can solve the problems of large steam volume and high cost of naphtha deoxygenation, and achieve the effect of reducing deoxygenation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

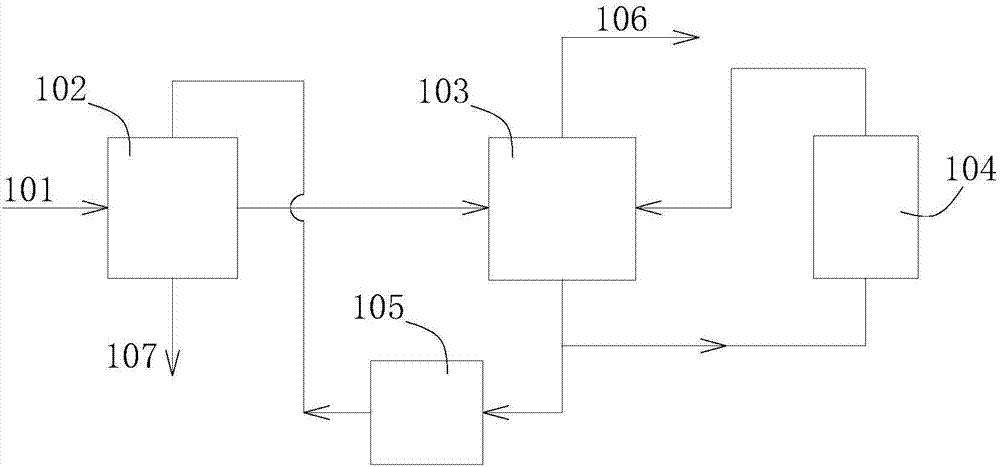

[0023] A kind of deoxygenation method of naphtha feedstock, see figure 1 , which includes the following processes:

[0024] (1) The raw naphtha 10 is heated by the raw material heater 20 and enters the deoxidation tower 30, and in the raw material heater, the raw naphtha is heated by a low-temperature heat source;

[0025] (2) In the deoxygenation tower 30, the reformed PSA analysis gas 40 is introduced, and the light components in the raw naphtha and the oxygen dissolved in the naphtha evaporate to the top of the tower together, and after cooling at the top of the tower, the light components formed The component condensate is pumped back into the tower to form a total reflux, and the non-condensable gas 50 enters the low-pressure gas system. The non-condensable gas includes reformed PSA desorption gas injected into the deoxidation tower and trace oxygen desorbed from naphtha and very small amounts of light components that are not condensed;

[0026] The deoxygenated naphth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com