Sprayed quick-setting waterproof rubber asphalt coating, and preparation and construction methods thereof

A technology of quick-setting rubber asphalt and waterproof coating, applied in the field of materials, can solve the problems of easy sticking to feet, damage of waterproof coating layer, poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

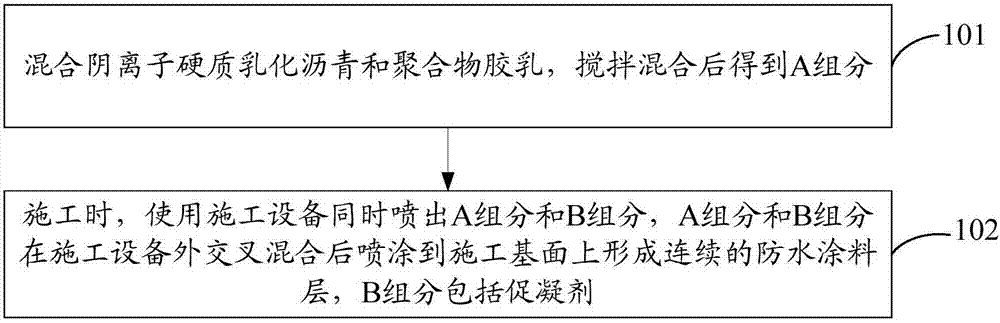

Method used

Image

Examples

preparation example Construction

[0050] According to the preparation and construction method of the above-mentioned waterproof coating, a continuous waterproof coating layer can be formed on the construction base surface, and the waterproof coating layer has higher tensile strength and better heat resistance.

[0051] Preferably, during the preparation and construction of the spraying quick-setting rubber asphalt waterproof coating, when the polymer latex is a modified polymer latex, the modified polymer latex is reacted with a carboxyl-containing polymer latex and a cross-linking agent that can react with a carboxyl group. When obtained, before step 101 is performed, the method may further include: mixing a carboxyl-containing polymer latex and a carboxyl-reactive cross-linking agent at 20-25° C. to obtain a modified polymer latex.

[0052] Based on the existence of the above-mentioned carboxyl reaction, the reaction between the carboxyl-containing polymer latex and the crosslinking agent is carried out at no...

Embodiment 1

[0055] Spray quick-setting rubber asphalt waterproof coating includes A component and B component.

[0056] Wherein, A component comprises the anionic hard emulsified bitumen of 90 parts by weight and the polymer latex of 10 parts by weight, and the penetration of anionic hard emulsified bitumen is 30-50; The parts by weight of B component is 15, Including inorganic salt coagulant;

[0057] Anionic hard emulsified asphalt includes SBR modified anionic hard emulsified asphalt;

[0058] Component B is an inorganic salt coagulant accelerator solution, the solvent is water, the inorganic salt coagulant includes calcium chloride, aluminum sulfate and zinc sulfate, and the concentration of component B is 15%.

[0059] The present invention tests the performance of the sprayed quick-setting rubber asphalt waterproof coating provided in this embodiment, and the test results show that the tensile strength of the sprayed quick-setting rubber asphalt waterproof coating reaches more than...

Embodiment 2

[0061] Spray quick-setting rubber asphalt waterproof coating includes A component and B component.

[0062] Wherein, A component comprises the anionic hard emulsified asphalt of 30 parts by weight and the polymer latex of 70 parts by weight, and the penetration of anionic hard emulsified asphalt is 30-50; The parts by weight of B component is 8, Including inorganic salt coagulant;

[0063] Anionic hard emulsified asphalt includes unmodified anionic hard emulsified asphalt;

[0064] Component B is an inorganic salt coagulation accelerator solution, the inorganic salt coagulation accelerator includes aluminum sulfate, and the concentration of component B is 20%.

[0065] The present invention tests the performance of the sprayed quick-setting rubber asphalt waterproof coating provided in this embodiment, and the test results show that the tensile strength of the sprayed quick-setting rubber asphalt waterproof coating reaches more than 1.5MPa, and the heat resistance reaches mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Heat resistance | aaaaa | aaaaa |

| Low temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com