Anti-collision chemical engineering charging basket

An anti-collision and chemical technology, which is applied in the direction of preventing mechanical damage, bottle/can parts, rigid containers, etc., can solve the problems of no anti-impact, etc., to prevent external impact, prevent the sleeve from falling off, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

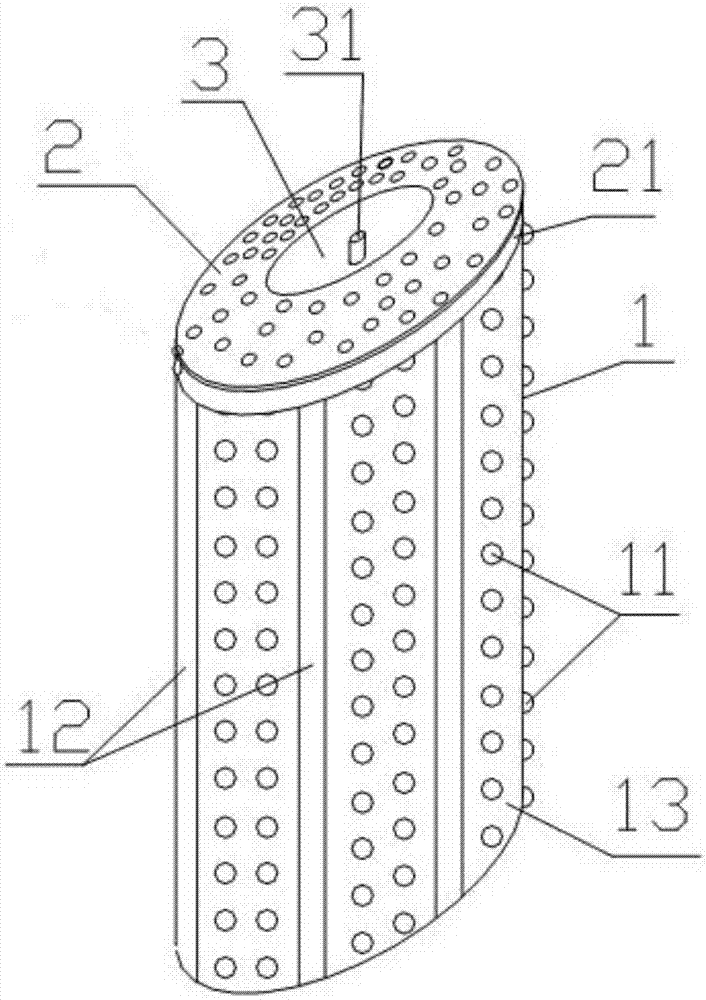

[0019] Such as figure 1 As shown, the present embodiment provides a kind of anti-collision chemical material barrel, a kind of anti-impact chemical material barrel, comprises barrel body and sleeve; There is a discharge hole in the middle of the lid; the sleeve is matched with the charging cylinder and set outside the charging cylinder, the bottom of the sleeve is a circular rubber ring, and the side wall of the sleeve It is surrounded by rubber belts arranged at intervals and longitudinal tightening belts; the zipper on the upper edge of the sleeve is connected with a ring-shaped shrinking ring that matches the barrel cover, and the ring-shaped shrinking ring is not far from the discharge hole. less than 2cm; the outer sides of the rubber band, the circular rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com