Cooling working table for plastic forklift plates after setting

A forklift plate and workbench technology, applied in applications, household appliances, other household appliances, etc., can solve the problems of time-consuming and laborious handling, large floor space, etc., and achieve the effects of improving stability, small footprint, and high cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

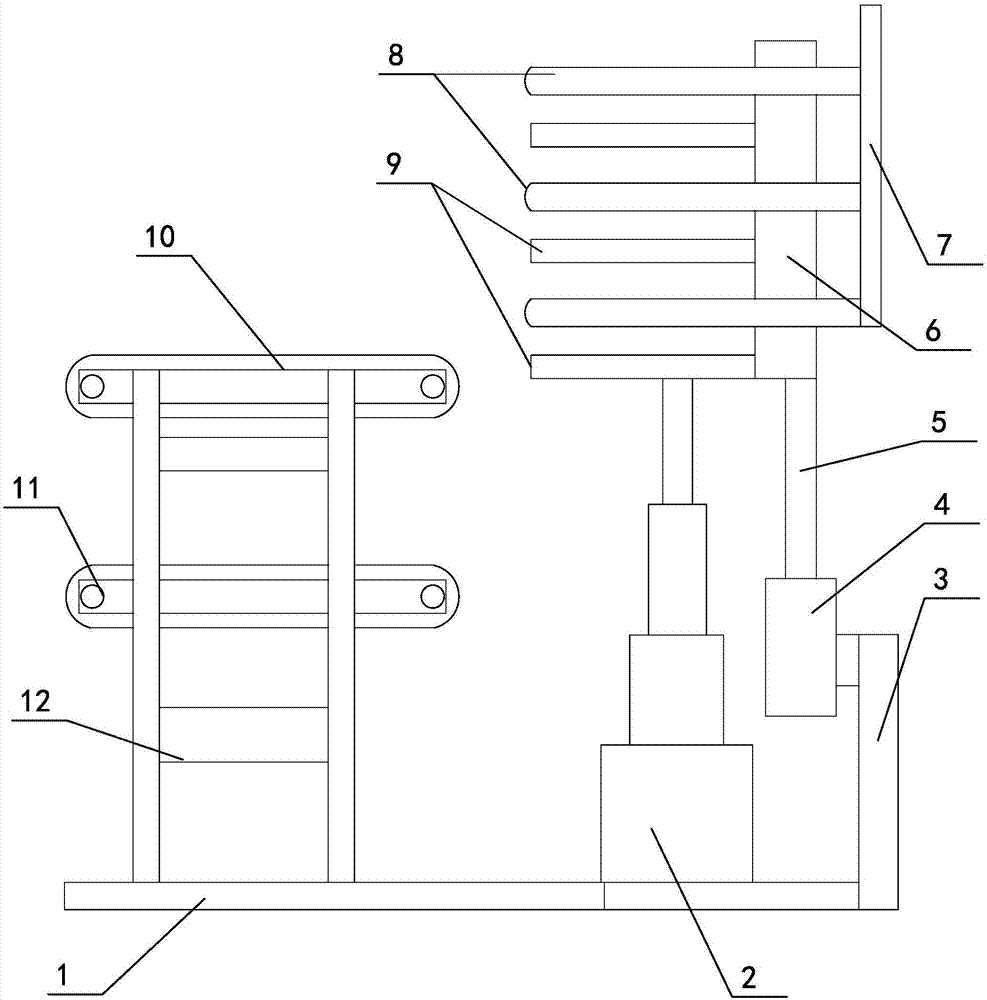

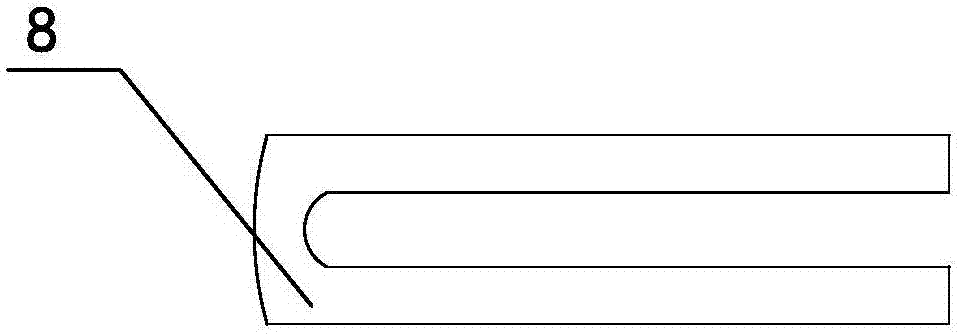

[0018] Such as figure 1 , figure 2 As shown, the cooling workbench for plastic forklift plates after finalization includes a horizontally arranged base plate 1, on which a mounting bracket 12 is vertically installed, and on the mounting bracket 12, there are progressively installed horizontally from top to bottom. The material conveyor 10 and the discharge conveyor 11 are vertically equipped with a support frame 3 on the bottom plate 1 on the right side of the mounting bracket 12, and are vertically fixed with a guide sleeve 4 on the left side of the support frame 3, and are worn in the guide sleeve 4. There is a guide rod 5 that slides up and down with it, a mounting plate 6 is vertically fixed on the top of the guide rod 5, a placement plate 9 is horizontally fixed on the left side of the installation plate 6, and a cooling circulation pipe 8 is horizontally arranged above the placement plate 9. The cooling circulation pipe 8 is in a "U" shape, and the cooling circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com